Solid thermal conductivity detector for cylindrical thermal sensitive region

A thermal conductivity detector and columnar technology, applied in the field of solid-state thermal conductivity detectors, can solve problems such as unusability, large output signal, noise, etc., and achieve the effects of excellent repeatability of response values, expansion of application range, and large surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

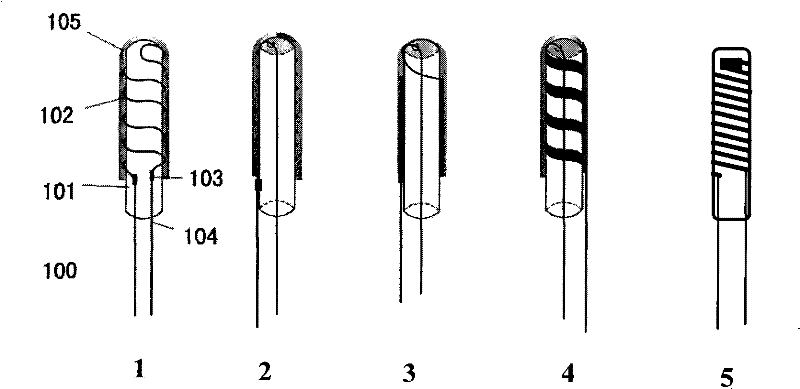

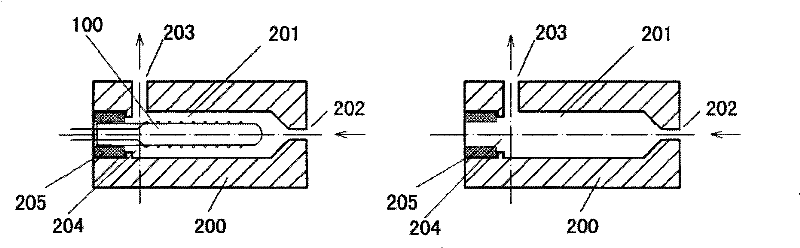

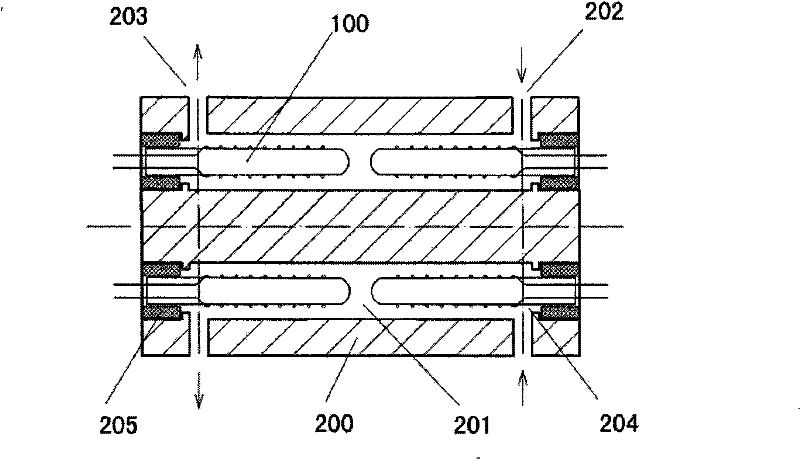

[0036] A solid-state thermal conductivity detector, on a ceramic rod 101 with a diameter of 0.6mm, a rhenium-tungsten alloy wire with a diameter of 15μm is used to wind a 100 ohm / 0°C thermistor 102, and the lead wire 103 is welded to the lead wire 104, and then the The surface is coated with a low-temperature ceramic protective layer 105 with a thickness of 2 microns. This component is referred to as thermal element 100 . The two fabricated thermosensitive elements 100 are respectively embedded in two flow cells 201 to form a detection cell, which has a gas inlet 202 and a gas outlet 203 respectively. The distance between the thermal wire 102 and the wall of the detection cell is 100-200 microns. This pair of heat-sensitive elements is connected with an external circuit to form a Wheatstone bridge.

[0037] Use two elastic quartz capillary columns with a length of 20 meters and an internal diameter of 0.53mm to be connected to the two inlets of the detector respectively, one...

Embodiment 2

[0039] Solid-state thermal conductivity detector, on a glass tube with an outer diameter of 1mm (as a support 101), a thermal electrode 102 with a resistance of 22 ohms / 0°C is wound with a platinum wire with a diameter of 20 μm, and the platinum wire lead 103 is welded to a fixed lead wire 104 , coating glass glaze with a thickness of about 1 μm on the surface of the heat-sensitive area to form a protective film 105 . The two fabricated thermosensitive elements are respectively embedded in the two flow cells 201 to form two independent detection cells. The distance between the surface of the heat-sensitive area and the wall of the detection pool is 200-300 microns. The inlet 202 of the detection cell is connected to the outlet of the chromatographic column, and the outlet 203 of the detection cell is emptied. This pair of heat-sensitive elements is connected with an external circuit to form a Wheatstone bridge.

[0040] Use two micro-packed stainless steel columns with a len...

Embodiment 3

[0042] On a quartz tube with an outer diameter of 0.8mm (as a support 101), a thermal electrode 102 with a resistance of 100 ohms / 0°C is wound with a platinum wire with a diameter of 10 μm, and the platinum wire lead 103 is welded to a fixed lead electrode 104. The surface is coated with 0.5 μm polyimide to form the protective layer 105 . The two fabricated thermosensitive elements are respectively embedded in the two flow cells 201 to form two independent detection cells. The distance between the surface of the thermistor wire and the wall of the detection cell is 50-180 microns, the inlet 202 of the detection cell is connected to the outlet of the chromatographic column, and the outlet 203 of the detection cell is emptied. This pair of heat-sensitive elements is connected with an external circuit to form a Wheatstone bridge.

[0043] Use two elastic quartz capillary columns with a length of 30 meters and an internal diameter of 0.53mm to be connected to the two inlets of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com