Bipolar transistor and manufacturing method thereof

A technology of bipolar transistor and manufacturing method, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problems of insufficient compatibility of bipolar transistor, difficulty in effectively controlling the breakdown voltage of emitter and collector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

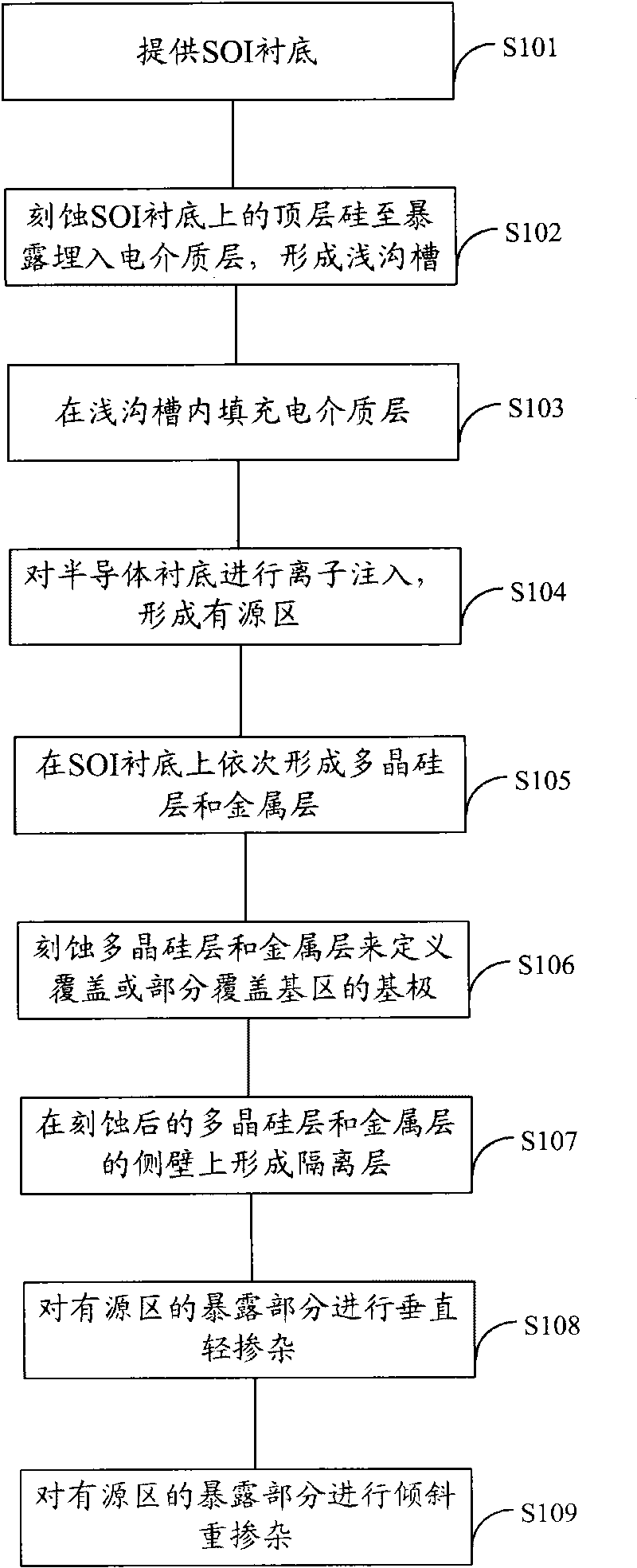

[0028] In the following, a bipolar transistor structure formed on an SOI (Silicon On Insulator, silicon-on-insulator) substrate and its manufacturing method are taken as an example, and the specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings.

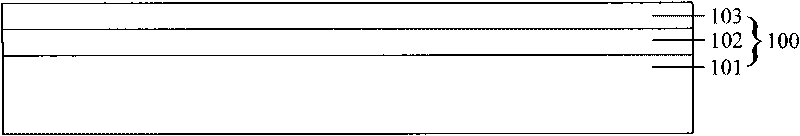

[0029] The SOI substrate has an underlying silicon substrate, a buried dielectric layer, and a first semiconductor material layer on the buried dielectric layer. The material of the first semiconductor material layer includes Si, Ge, SiGe, GaAs, InP, InAs or InGaAs, etc. In Embodiment 1, the material of the first semiconductor material layer is silicon as an example for detailed description.

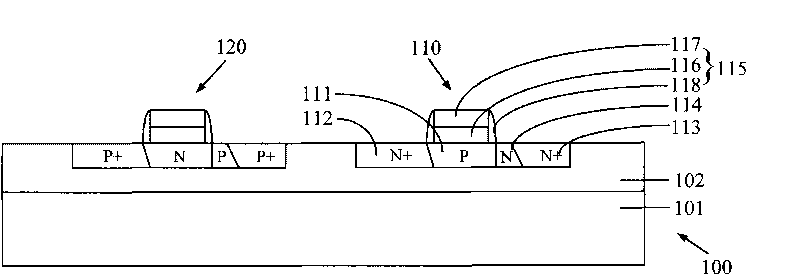

[0030] Such as figure 1 As shown, on the top layer silicon 103 of the SOI substrate 100 (reference image 3 ) is formed with an NPN bipolar transistor 110. The NPN bipolar transistor 110 includes a P-type base region 111 , an N-type emitter region 112 and an N-type col...

Embodiment 2

[0066] In this specific embodiment, a special bipolar transistor structure with a buffer zone formed on an SOI substrate and its manufacturing method are also provided, which will be described below with reference to the accompanying drawings.

[0067] Such as Figure 12 and Figure 13 As shown, the present embodiment provides a bipolar transistor 201 formed on an SOI substrate 220, including a metal base 202 formed of metal and a cylindrical semiconductor material column 203 (refer to Figure 20 ). The semiconductor material pillar 203 is, from one end to the other end, an emitter region 204 , a base region 205 , a buffer region 208 and a collector region 206 of the bipolar transistor 201 in sequence. A through hole 207 is formed in the metal base 202 , and the base region 205 is located in the through hole 207 , that is, the metal base 202 forms a wrap around the base region 205 and exposes the emitter region 204 and the collector region 206 . The length of the base regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com