Three-dimensional photoetching method for antenna manufacture

A three-dimensional, lithography technology, applied in antennas, antenna parts, optics, etc., can solve the problems of difficult production and assembly of RF components, unstable coordination relationship, and changes in RF performance, reducing raw material costs, shortening design cycles, Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Describe in detail below in conjunction with accompanying drawing.

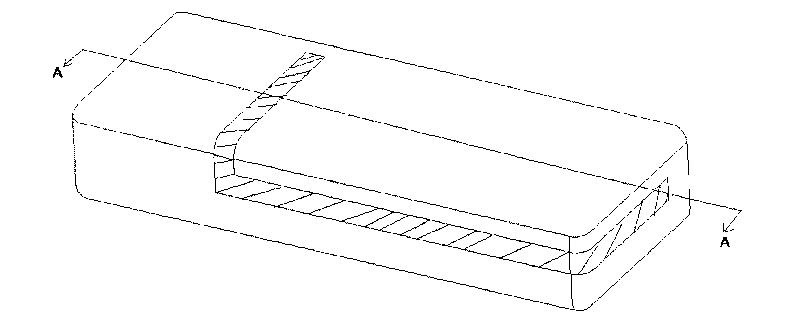

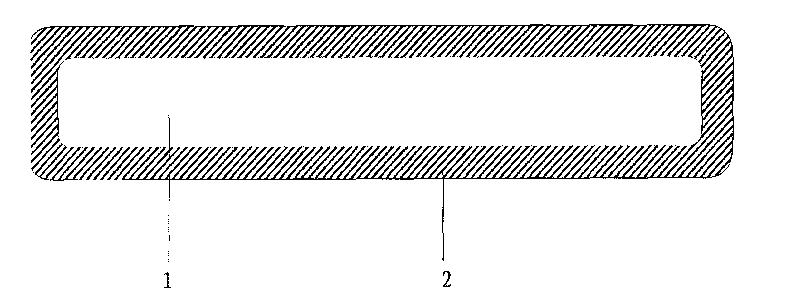

[0037] figure 1 It is the final schematic diagram of the present invention. figure 1 The shaded part of is the shape of the antenna. It can be seen that the shape of the antenna is distributed on three planes, which is three-dimensional. Therefore, the present invention is to complete the fabrication of three-dimensional antennas at one time, rather than only for two-dimensional planes. The fabrication of two-dimensional planar antennas is a special case of this method. The antenna pattern in this example is arbitrary, and its specific production aspects are as follows:

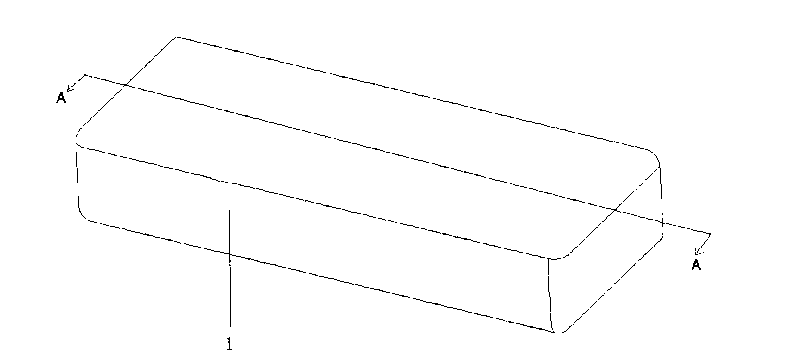

[0038] first step, such as figure 2 , providing a base structural member 1 .

[0039] The base structural member 1 can be made of metallizable plastic such as ABS, etc., by traditional techniques such as injection molding, and its shape can be customized as required. The base structural member 1 is three-dimensional, and any th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com