Drive of light emitting diode (LED) light source

A technology of LED light source and driver, which is applied in the field of LED light source and can solve problems such as the short board of LED driver quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

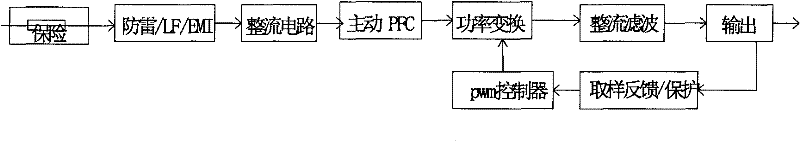

Problems solved by technology

Method used

Image

Examples

Embodiment 1

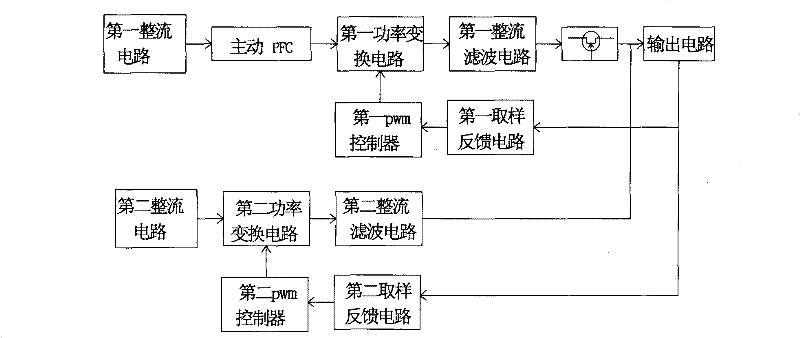

[0054] Such as figure 2 As shown, a driver for an LED light source includes a main circuit, and the main circuit includes:

[0055] The first rectification circuit, the input end of which is connected to the mains, converts the mains from AC to pulsating DC;

[0056] Active PFC, connected in series to the output circuit of the first rectifier circuit, corrects the phase of the input voltage and current through high-frequency pulse switching, so as to improve the power factor of the entire power supply;

[0057] The first power conversion circuit is connected in series to the output circuit of the active PFC, and the high-voltage pulse current is converted into low-voltage and high-current alternating current through a power transformer, and at the same time, high-voltage and low-voltage electrical isolation is provided;

[0058] The first rectification filter circuit is connected in series to the output circuit of the first power conversion circuit, and converts the high-fre...

Embodiment 2

[0071] Such as image 3 As shown, a driver for an LED light source includes a main circuit, and the main circuit includes:

[0072] The first rectification circuit, the input end of which is connected to the mains, converts the mains from AC to pulsating DC;

[0073] Active PFC, connected in series to the output circuit of the first rectifier circuit, corrects the phase of the input voltage and current through high-frequency pulse switching, so as to improve the power factor of the entire power supply;

[0074] The first power conversion circuit is connected in series to the output circuit of the active PFC, and the high-voltage pulse current is converted into low-voltage and high-current alternating current through a power transformer, and at the same time, high-voltage and low-voltage electrical isolation is provided;

[0075] The first rectification filter circuit is connected in series to the output circuit of the first power conversion circuit, and converts high-frequenc...

Embodiment 3

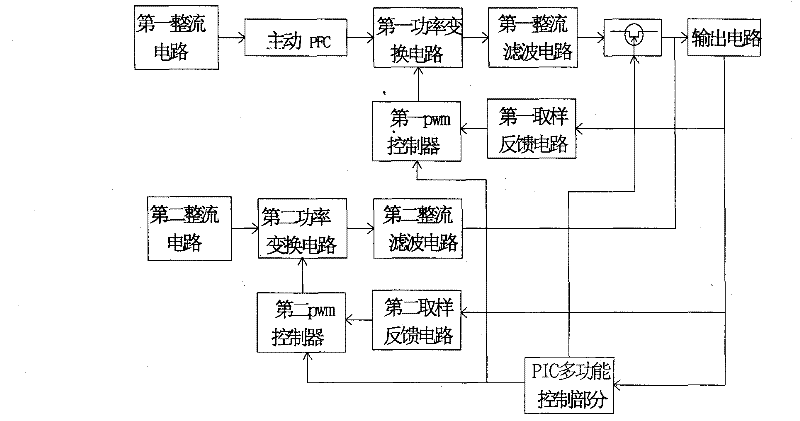

[0089] Such as Figure 4 As shown, a driver for an LED light source includes a main circuit, and the main circuit includes:

[0090] The first rectification circuit, the input end of which is connected to the mains, converts the mains from AC to pulsating DC;

[0091] Active PFC, connected in series to the output circuit of the first rectifier circuit, corrects the phase of the input voltage and current through high-frequency pulse switching, so as to improve the power factor of the entire power supply;

[0092] The first power conversion circuit is connected in series to the output circuit of the active PFC, and the high-voltage pulse current is converted into low-voltage and high-current alternating current through a power transformer, and at the same time, high-voltage and low-voltage electrical isolation is provided;

[0093] The first rectification filter circuit is connected in series to the output circuit of the first power conversion circuit, and converts high-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com