Dual-bulb tube high-voltage oil tank

A high-pressure fuel tank and bulb technology, applied in X-ray equipment, electrical components, etc., can solve problems such as complex structure, achieve small size, improve X-ray quality, and reduce ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

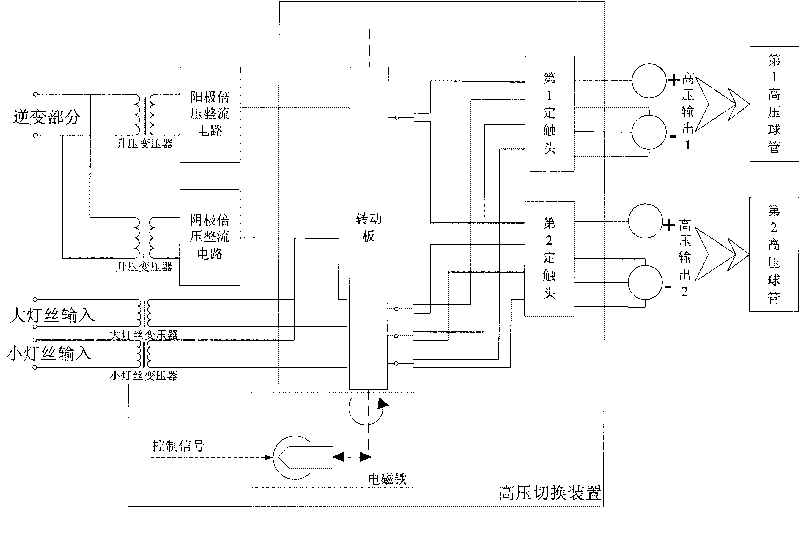

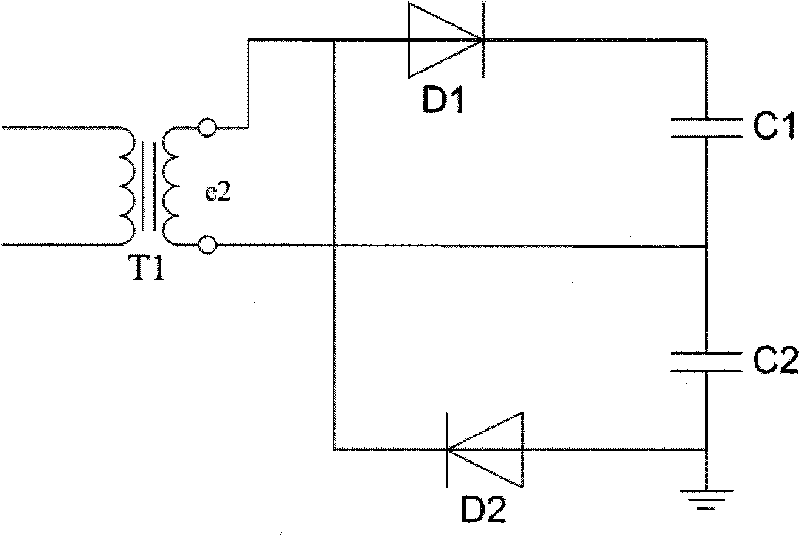

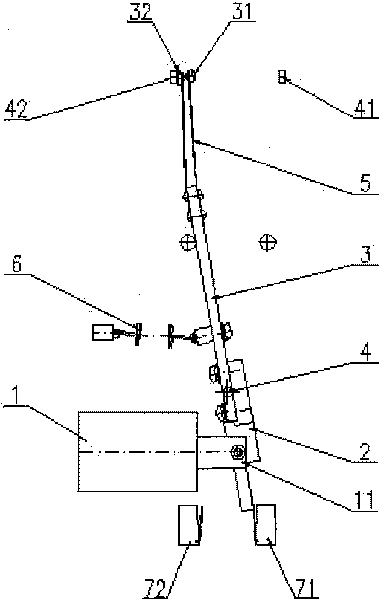

[0017] like figure 1 , 2 As shown, the double-tube high-pressure fuel tank of the present invention is installed in the X-ray high-voltage generator, and is provided with a voltage doubler rectifier circuit in the high-pressure fuel tank (i.e. figure 1 The anode voltage doubler rectifier circuit and cathode doubler rectifier circuit), step-up transformer, filament transformer and high voltage switching device are all immersed in insulating oil. There is also an insulating framework inside the oil tank, on which the voltage doubler rectifier circuit, step-up transformer, filament transformer and high-voltage switching device are all fixedly installed, which can ensure reliable insulation between each part and between each part and the tank. The primary winding of the step-up transformer is connected to the inverter part of the high-voltage generator, and the voltage output by the inverter part is boosted and then output to the voltage doubler rectifier circuit through the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com