Scale type helical-flow air concentrating and separating device

A spiral flow and separator technology, applied in the field of gas separation devices, can solve the problems of waste of resources, mine danger and high concentration, and achieve the effects of simple structure, large gas processing capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

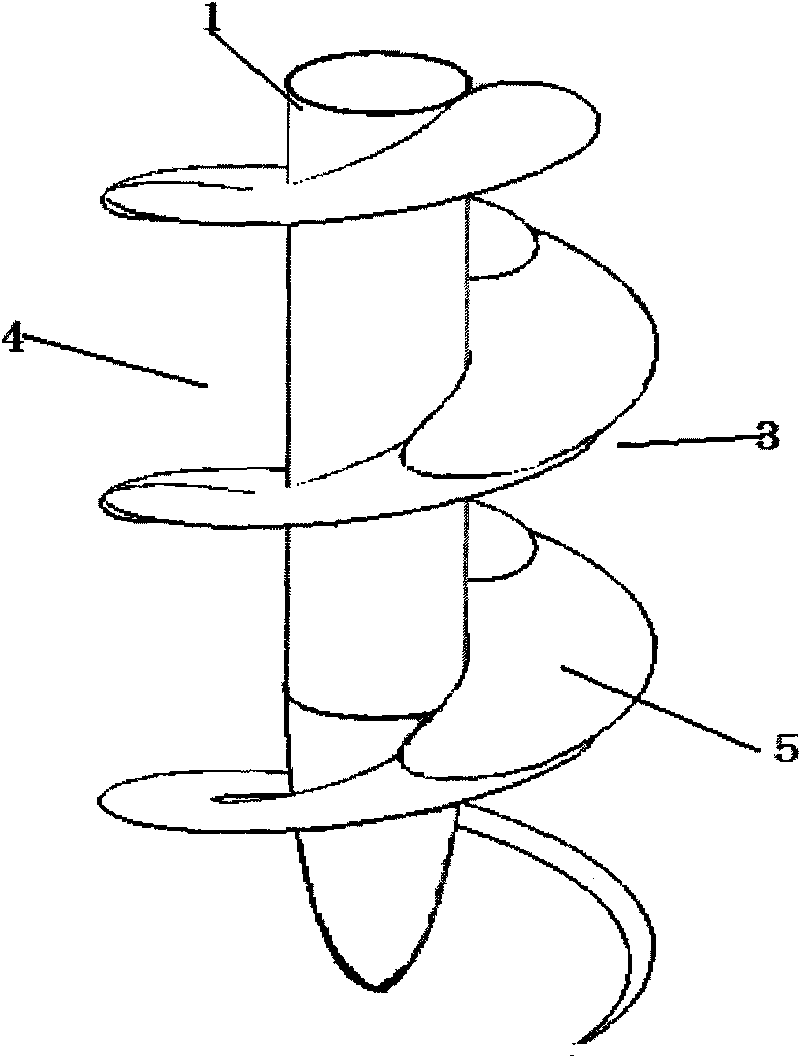

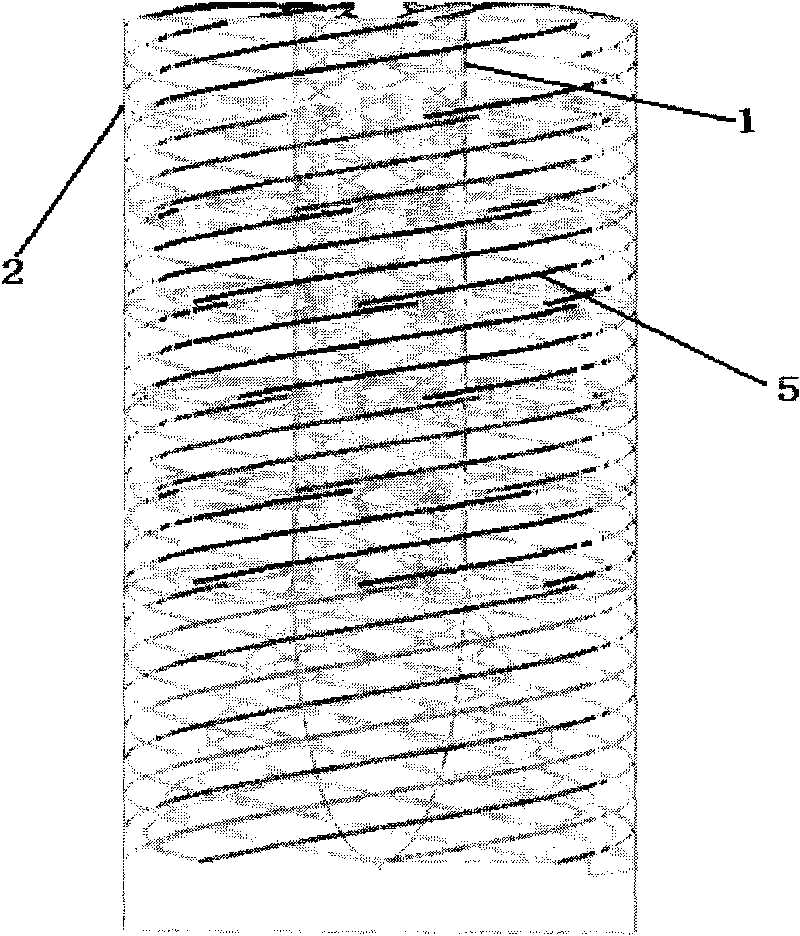

[0018] like figure 1 , 2 As shown, a scale-type spiral flow gas concentration separator includes an inner cylinder 1, an outer cylinder 2, and a spiral panel 3, and the spiral panel 3 is arranged on the inner cylinder 1 in a spiral manner along the inner cylinder 1 Between the outer surface of the outer cylinder 2 and the inner surface of the outer cylinder 2, the spiral panel 3 and the outer surface of the inner cylinder 1 and the inner surface of the outer cylinder 2 form a spiral flow channel 4.

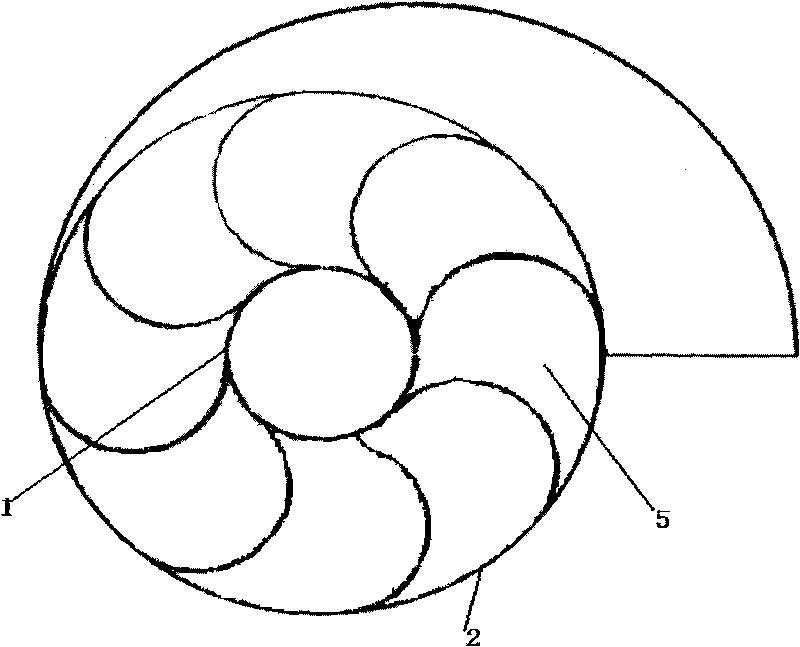

[0019] image 3 It is a top view of the scale-type spiral flow gas concentration separator of the present invention, and the spiral panel 3 is composed of short spiral channel plates 6 overlapped head to tail. like figure 2 As shown, gaps are provided between the short spiral path plates 5 at the joints of the short spiral path plates 5 .

[0020] The scale-type spiral flow gas concentration separator has the outer surface of the inner cylinder 1 and the inner surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com