Lubricating device for bearing on vertical shaft of disc-type separator

A disc separator, bearing lubrication technology, applied in the direction of engine lubrication, centrifuges, mechanical equipment, etc., can solve the problems of inconvenient processing and maintenance, high mechanical cost, and achieve effective heat dissipation, low cost, and simple lubrication structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with embodiment the present invention is described in further detail.

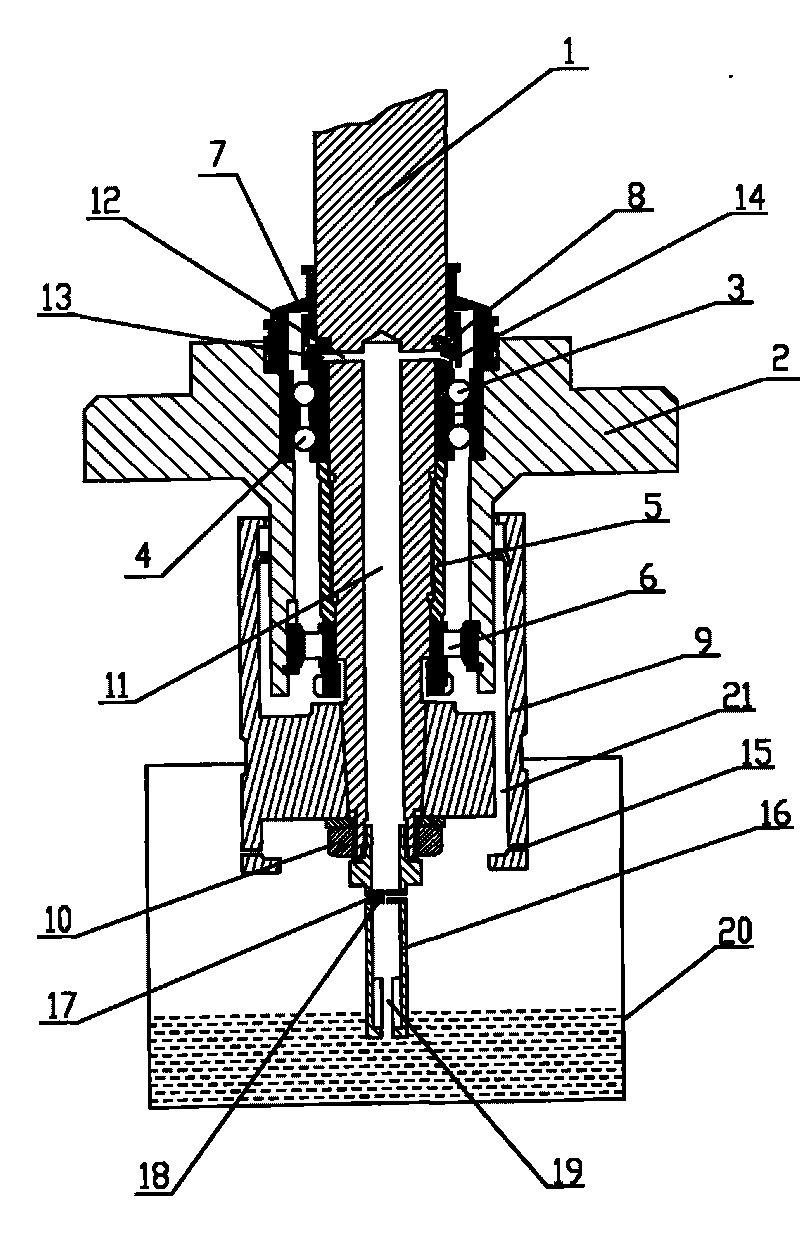

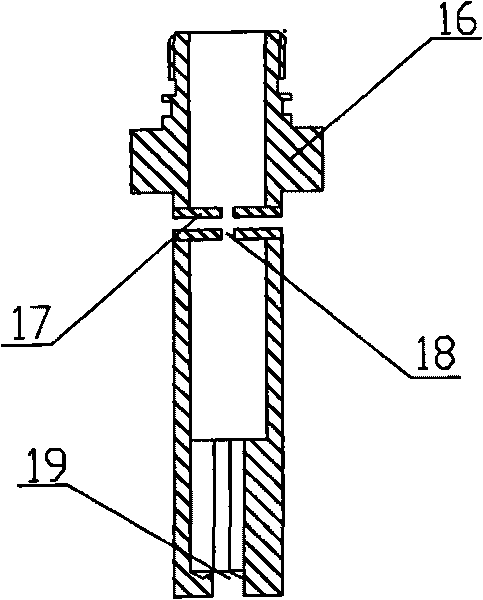

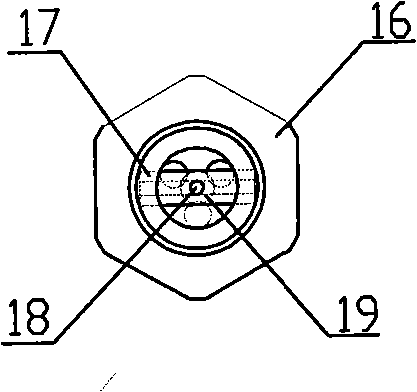

[0010] Depend on figure 1 , figure 2 and image 3 It can be seen that the bearing lubricating device on the vertical shaft of a disc separator according to the present invention includes a vertical shaft 1, a bearing seat 2, an upper bearing I3, an upper bearing II4, a spacer sleeve 5, a lower bearing 6, a gland 7, and a lubricating sleeve 8 , pulley 9, parallel nut 10; upper bearing I3, upper bearing II4, spacer sleeve 5, and lower bearing (6) are installed in the bearing seat 2 in sequence, and vertical shaft 1 passes through upper bearing I3, upper bearing II4, and spacer sleeve 5 in sequence , the lower bearing 6, a lubricating sleeve 8 is set on the vertical shaft 1 above the upper bearing 13, a gland 7 is also set on the vertical shaft 1 above the lubricating sleeve 8, and the belt pulley 9 is fixedly set on the vertical shaft 1 below the bearing seat 2, The central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com