A low-voltage power cabinet

A low-voltage power cabinet technology, applied in electrical components, substation/switch layout details, substation/distribution device shell, etc., can solve problems such as easy heating and poor cooling effect of low-voltage power cabinets, and achieve high heat dissipation efficiency. Good effect and easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

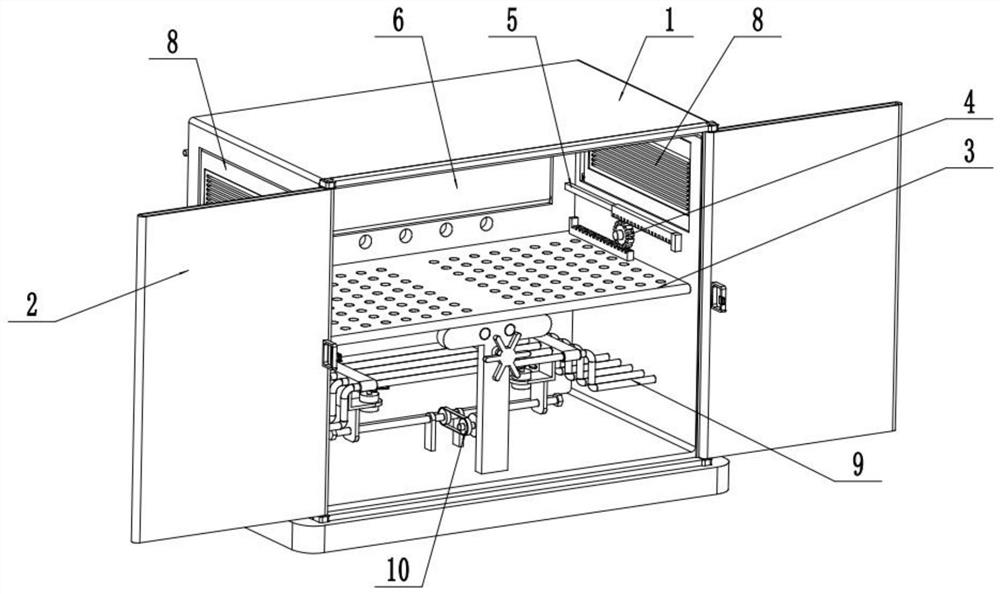

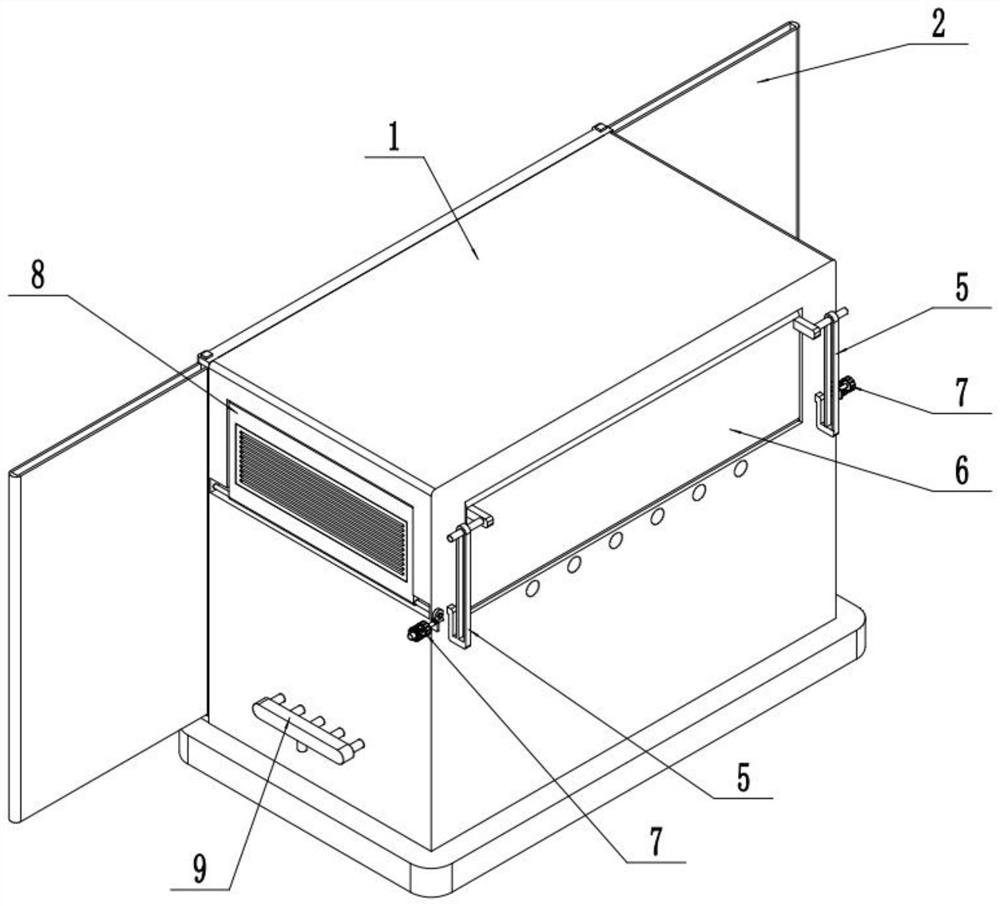

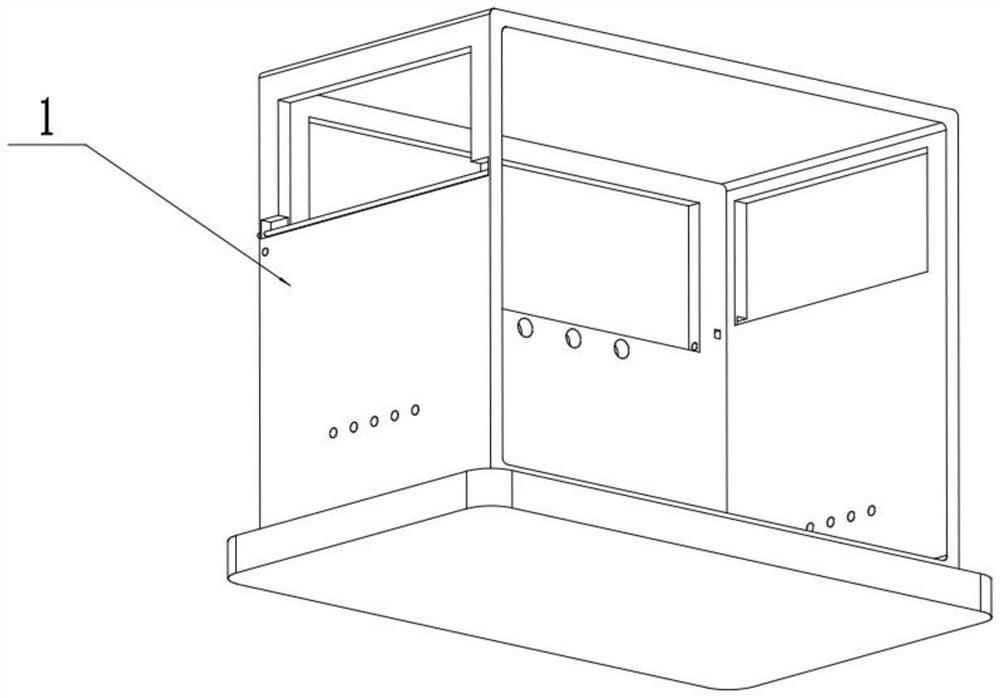

[0035] like Figure 1-15 As shown, a low-voltage power cabinet includes a cabinet body 1, a front cabinet door mechanism 2, a movable mounting plate mechanism 3, a direction changing wheel mechanism 4, a linkage opening and closing mechanism 5, a rear cabinet door mechanism 6, a transmission wheel mechanism 7, a side Cabinet door mechanism 8, water cooling mechanism 9 and air cooling mechanism 10, the front end of the cabinet body 1 is fixedly connected to the front cabinet door mechanism 2; the upper end of the movable mounting plate mechanism 3 is connected to the middle end inside the cabinet body 1, and is movably installed The lower end of the plate mechanism 3 is connected to the bottom surface inside the cabinet body 1; the left and right ends of the movable mounting plate mechanism 3 are respectively meshed and connected to a steering wheel mechanism 4, and the two steering wheel mechanisms 4 are respectively meshed and driven to connect a linkage. The opening and clos...

specific Embodiment approach 2

[0037] like Figure 1-15 As shown, the front cabinet door mechanism 2 includes an upper rectangular rod 2-1, a lower rectangular rod 2-2, a left rectangular rod 2-3, a right rectangular rod 2-4, a left sliding door 2-5, and a right sliding door 2 -6 and handle 2-7; the upper rectangular rod 2-1, the right rectangular rod 2-4, the lower rectangular rod 2-2 and the left rectangular rod 2-3 are sequentially fixed and connected to form a rectangular frame; the upper rectangular rod 2-1 and the rear ends of the lower rectangular rod 2-2 are respectively fixedly connected to the upper and lower ends of the front side of the cabinet body 1; the inner side of the left sliding door 2-5 is provided with a left rectangular sliding hole, and the left sliding door 2-5 The left rectangular sliding hole is slidably connected to the left rectangular rod 2-3; the inner side of the right sliding door 2-6 is provided with a right rectangular sliding hole, and the right sliding door 2-6 is slidab...

specific Embodiment approach 3

[0039] like Figure 1-15 As shown, the movable mounting plate mechanism 3 includes a mounting plate body 3-1 with a plurality of bolt connection holes on the top surface, a driving rack 3-2, a rear limit baffle 3-3, and a horizontal movable seat 3-4 , guide shaft 3-5, adjusting screw 3-6, screw disc 3-7, T-shaped vertical plate 3-8, hexagonal column 3-9 and tension spring 3-10; the top surface of the mounting plate body 3-1 The left and right ends of the driving rack 3-2 are respectively fixedly connected to a driving rack 3-2, the rear end of the top surface of the driving rack 3-2 is fixedly connected to the rear limit baffle 3-3, and the two driving racks 3-2 are meshed and connected to one The direction changing wheel mechanism 4; the horizontal movable seat 3-4 is fixedly connected to the rear end of the bottom surface of the mounting plate body 3-1; the front and rear ends of the guide shaft 3-5 are respectively fixedly connected to the T-shaped vertical plate 3-8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com