High-temperature slag handling technology by tilting roller process and device

A treatment device and drum method technology, applied in the field of high-temperature slag treatment, can solve problems such as poor feeding, complex structure, deposition, etc., and achieve stable performance and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

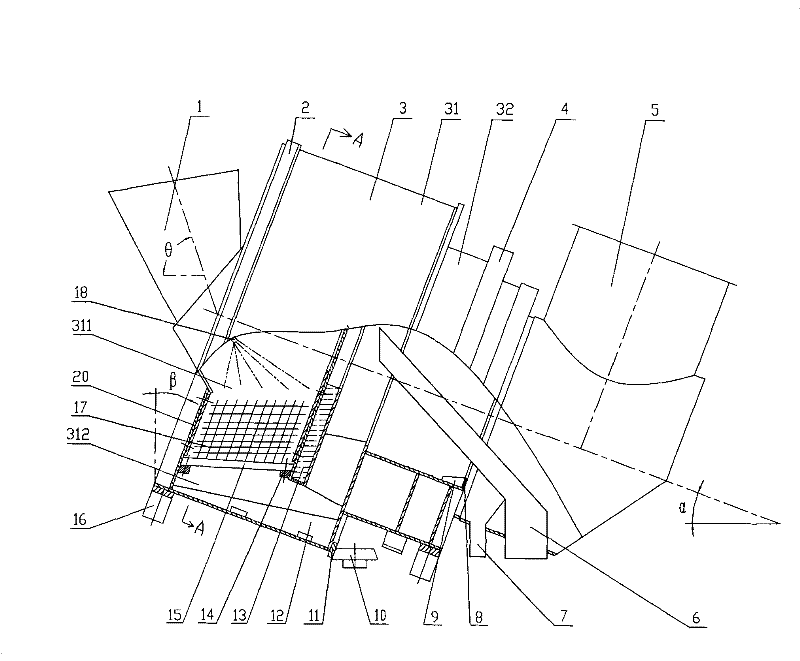

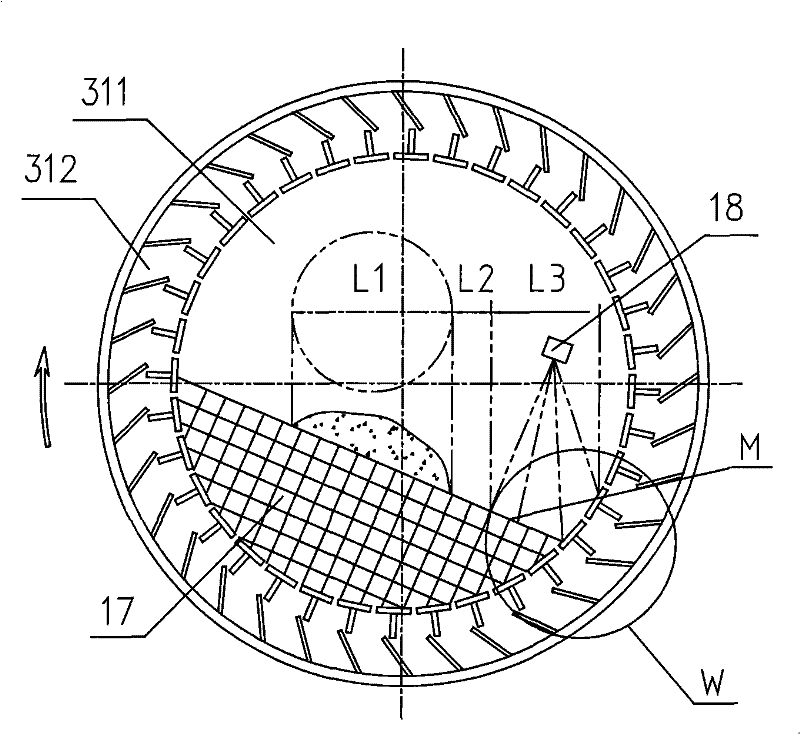

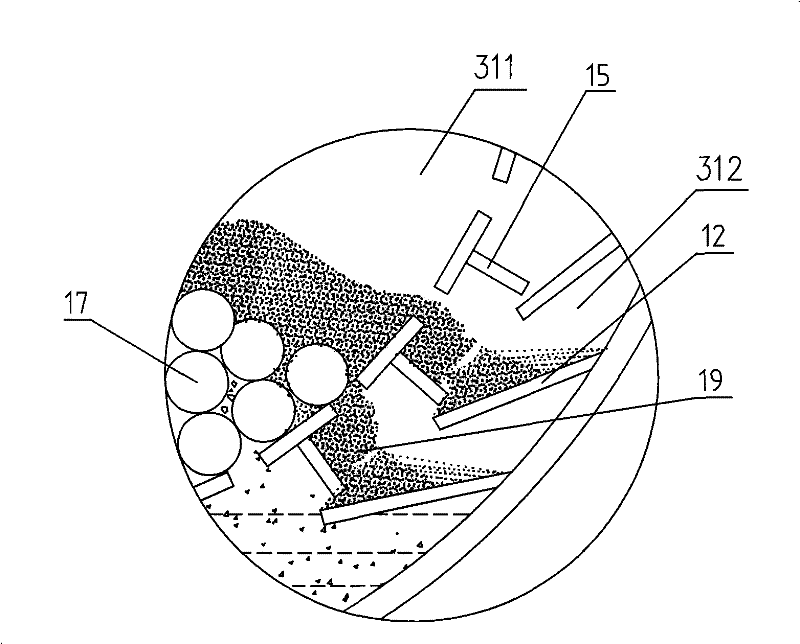

[0030] see figure 1 , an inclined drum method high-temperature slag treatment device, including a feed hopper 1, a drum device, a thrust device 10, a discharge chute 6, and a gas collection and discharge device 5. The drum device includes a working cylinder 3 composed of a front cylinder 31 and a rear cylinder 32, a nozzle 18 installed in the front cylinder 31, a device for supporting and driving the working cylinder. The front cylinder 31 is composed of an inner cylinder 311 and an outer cylinder 312. The inner cylinder 311 is composed of an end cover 20, an end motherboard 135, a liner 131, and several grate bars 15; the outer cylinder 312 is set inside The outside of the cylinder 311 is fixed by rigid parts, and the inner surface of the outer cylinder 312 is equipped with a plurality of evenly distributed cylinder lifting plates 12 with dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com