Installation method of complicated group anchors

An installation method and complex technology, which is applied in the direction of construction and building construction, can solve problems affecting building quality, anchor bolt slippage, large errors, etc., and meet the requirements of installation accuracy, accurate installation position, and avoid secondary errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purpose of the present invention is to provide a method for installing complex group anchors, which can meet the installation accuracy requirements of self-cutting bottom anchor bolts, and has accurate installation positions and good fixing effects.

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

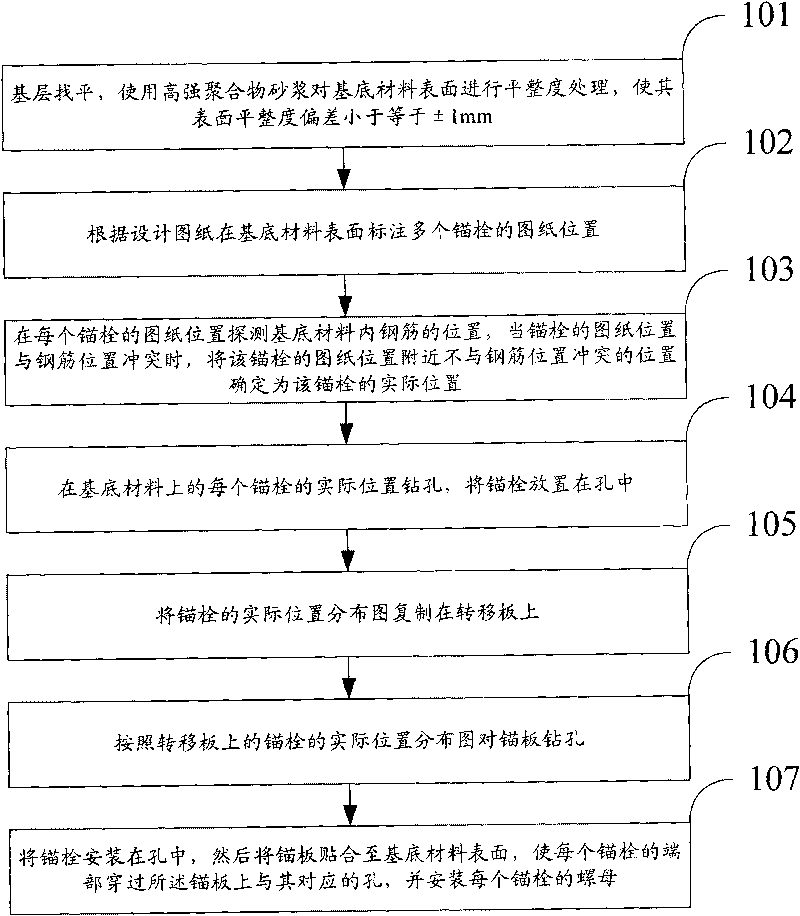

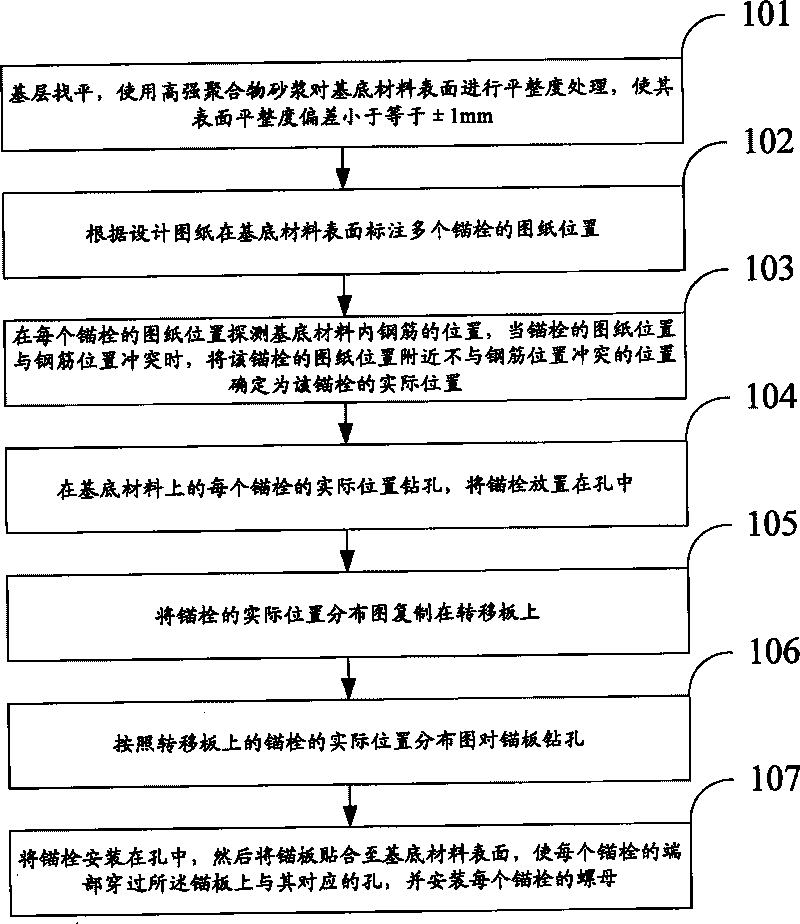

[0037] figure 1 It is a flow chart of the complex group anchor installation method of the present invention. like figure 1 As shown, the installation method of the complex group anchor of the present invention is used to fix the anchor plate to the surface of the base material, the method comprising:

[0038] Step 101, leveling the base, using high-strength polymer mortar to smoothen the surface of the base material, so that the deviation of the flatness of the surface is less than or equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com