Totally-prefabricated assembling type reinforced concrete floor system

A reinforced concrete and prefabricated assembly technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of damage, difficult to repair, poor integrity of the floor, achieve clear force, reasonable structure, improve in-plane stiffness and The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

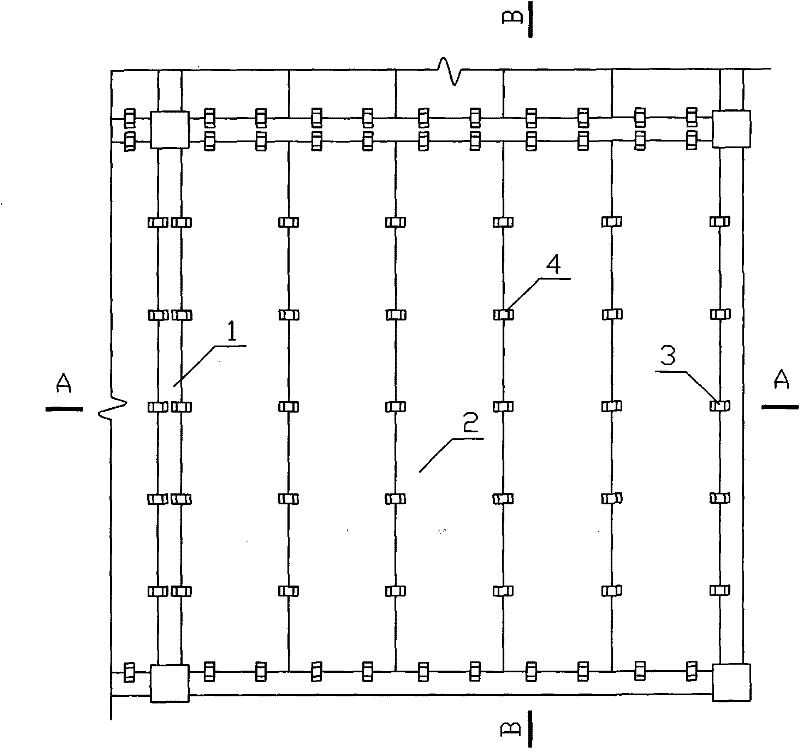

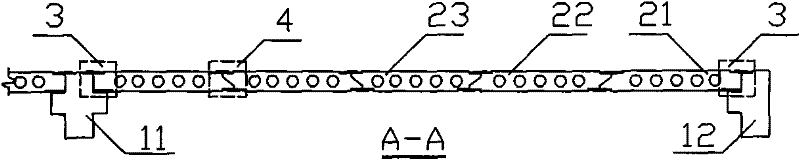

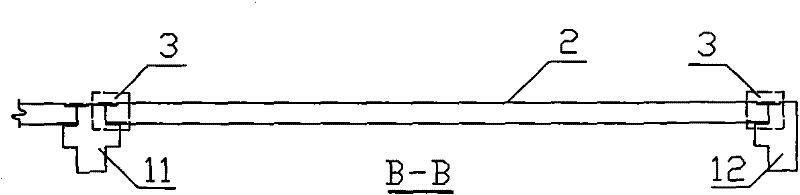

[0021] The fully prefabricated reinforced concrete floor system includes beams 1 and prefabricated slabs 2. 22 and the middle plate 23, and one side of the side plate 21 is overlapped with the beam, and the other side of the middle plate 23, the common plate 22 and the side plate 21 are overlapped sequentially, and it is characterized in that the beam 1 is an ear beam , the middle plate 23, the common plate 22 and the side plate 21 are all grooved and grooved, and the both sides of the middle plate 23 are grooved and grooved, and the both sides of the common plate 22 are grooved and grooved respectively. The other side of the side plate 21 is an upper tongue and groove, the prefabricated panels are connected by the panel-slab connector 4, and the prefabricated panel 2 and the beam 1 are connected by the beam-slab connector 3;

[0022] The plate-plate connector 4 includes a top metal cover plate 42, a bottom metal cover plate 44, and a first plate top embedded metal plate 41 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com