Downdraft high-voltage electric diving pump used for explosion-proof type mines and wells

A submersible electric pump, flameproof technology, applied in the direction of non-variable-capacity pumps, pumps, pump devices, etc., can solve the problems of limited use conditions of submersible pumps, cannot be inclined, used horizontally, and is not suitable for flammable and explosive , to achieve the effect of long maintenance cycle, extended service life and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

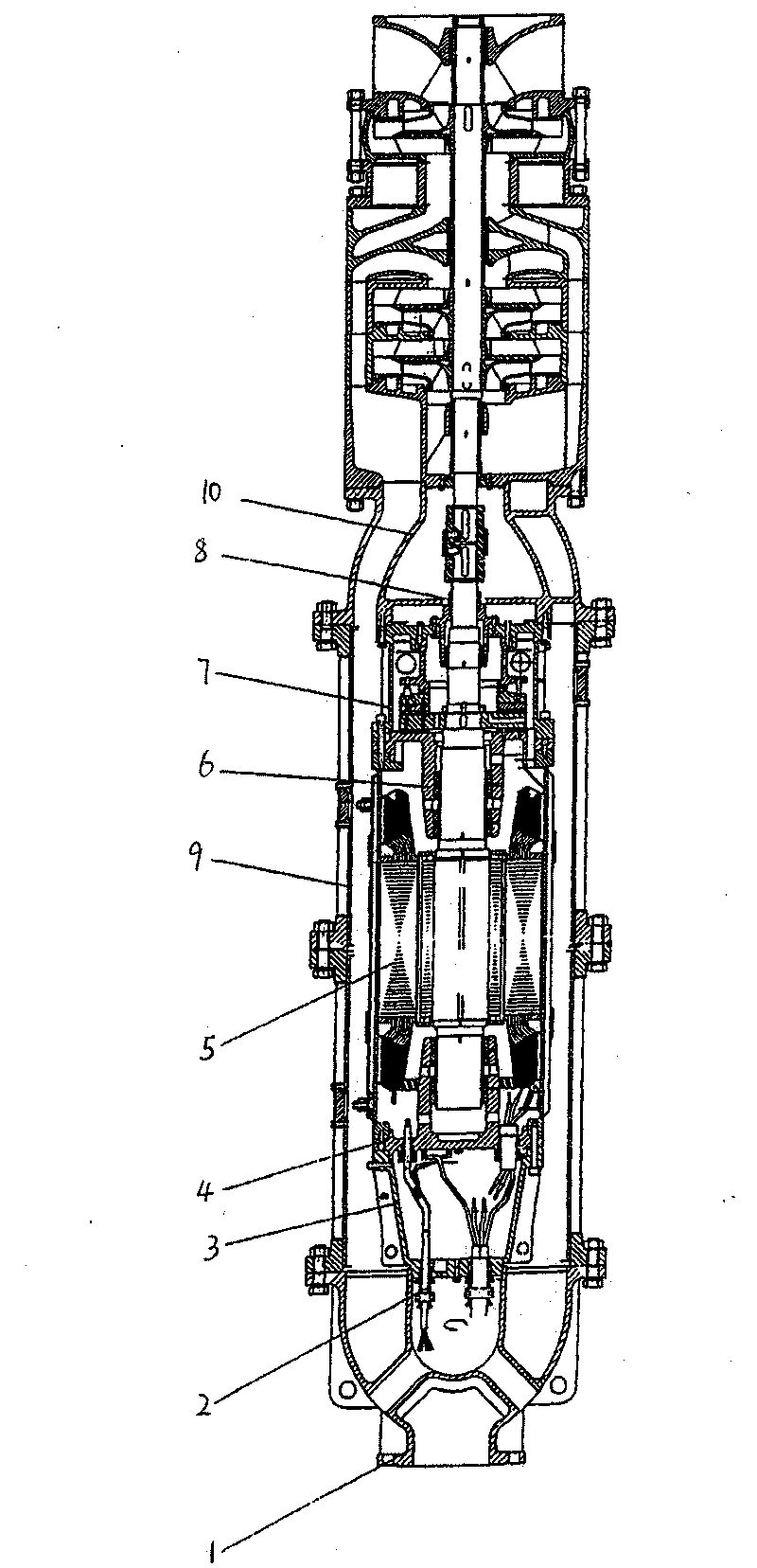

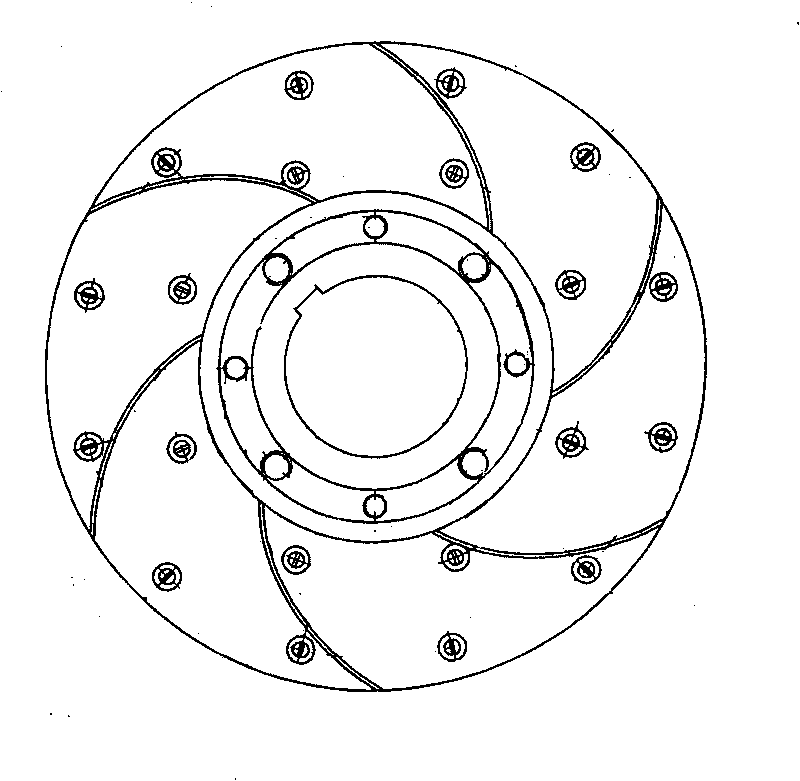

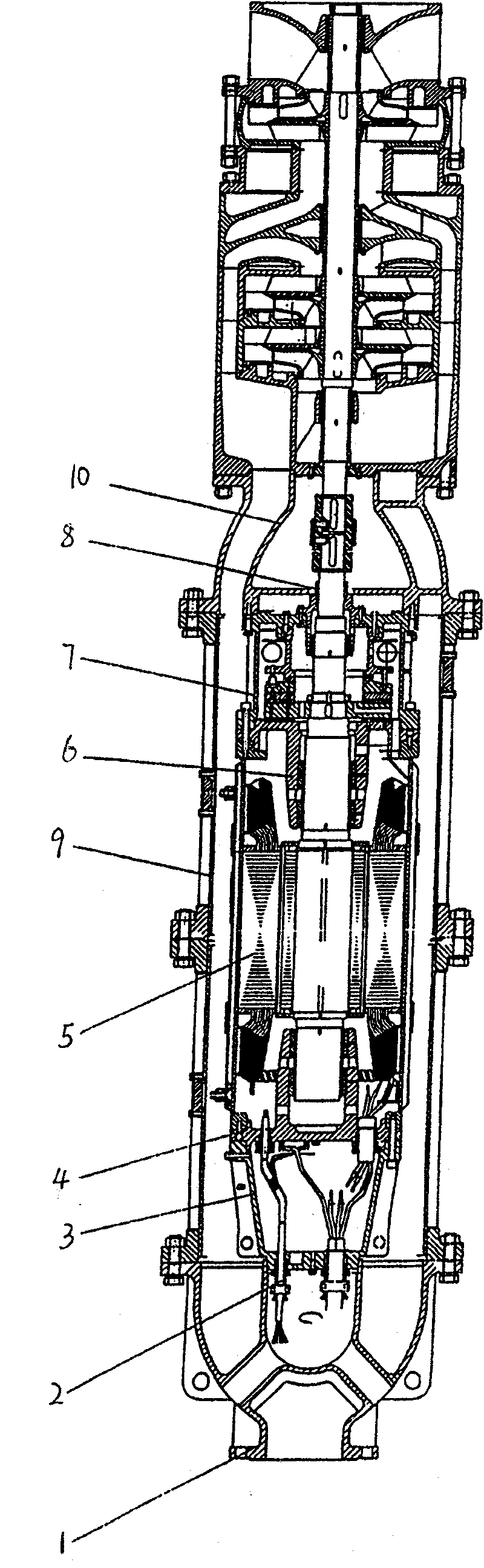

[0011] like figure 1 As shown, the present invention consists of a single-suction guide vane centrifugal pump and a water-filled explosion-proof high-voltage three-phase asynchronous motor. The explosion-proof protection of the present invention is composed of four layers, and the components of the motor inner cavity protection layer include the lead-out cable assembly (2), the rear part is sequentially connected with the junction box assembly (3), the upper guide bearing (4), the stator (5) connected with the upper guide bearing (4), and the lower guide bearing connected with the stator (5) ( 6), the rear thrust bearing assembly (7) and mechanical seal assembly (8), the components are connected by bolts; this layer forms the key first layer of flameproof protection; the second layer of protection consists of The water outlet body (1) at the top, the external water absorption cover (9) and the connection body (10) connected with the down suction pump; the other two layers of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com