High-temperature and high-pressure sealing device for small optical fiber sensor test

An optical fiber sensor, high temperature and high pressure technology, applied in the field of sensor testing, can solve the problems of repeated sealing of sensors, inconvenient operation, sensor damage, etc., and achieve the effects of simple structure, improved safety, and avoiding accidental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

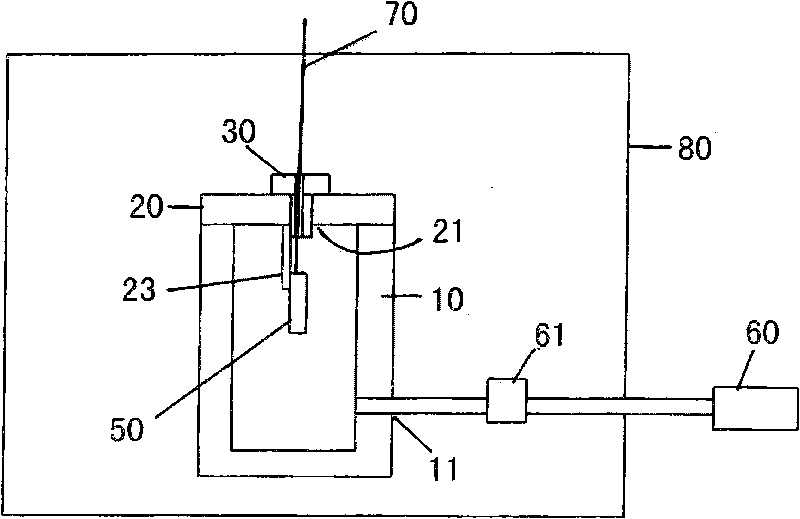

[0038] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of high temperature and high pressure sealing device that is used for small-scale optical fiber sensor experiment, comprises:

[0039] A high-pressure tank 10, which is cylindrical or rectangular, has a circular hole 11 on the side wall of the high-pressure tank 10, and has an optical fiber sensor 50 inside the high-pressure tank 10;

[0040] A sealing cover 20, sealing the high-pressure tank 10, has a screw hole 21 in the center of the sealing cover 20; at least one optical fiber sensor holder 23 is installed on the inner wall of the sealing cover 20, which is used to fix the optical fiber sensor 50 in the sealing tank position in 10;

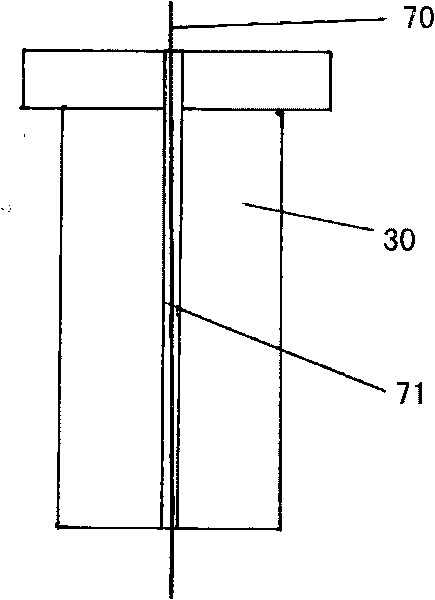

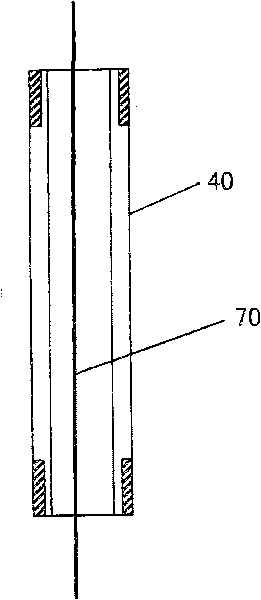

[0041] A bolt 30, the bolt 30 cooperates with the screw hole 21 on the sealing cover 20, and the longitudinal center of the bolt 30 has a through hole 31; a capillary 40 is further installed in the through hole 31 of the bolt 30 to enhance the sealing effect; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com