Accelerated test method of non-uniform corrosion in inbuilt electrode simulation concrete

An accelerated test, built-in electrode technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as failure to truly reflect the performance of reinforced concrete components, gaps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

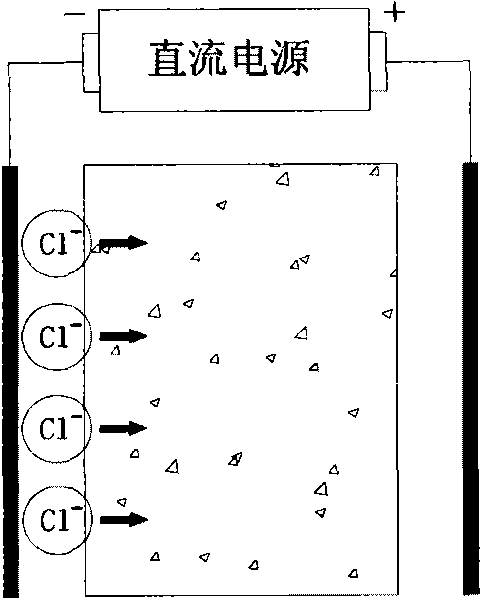

[0060] Simulate the non-uniform corrosion state of concrete in a marine environment.

[0061] (1) Preparation of concrete specimens:

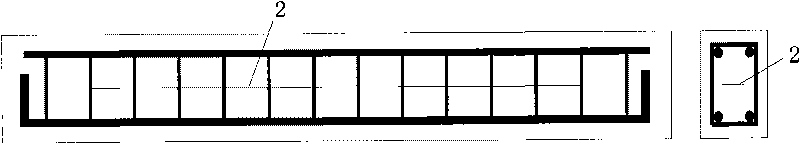

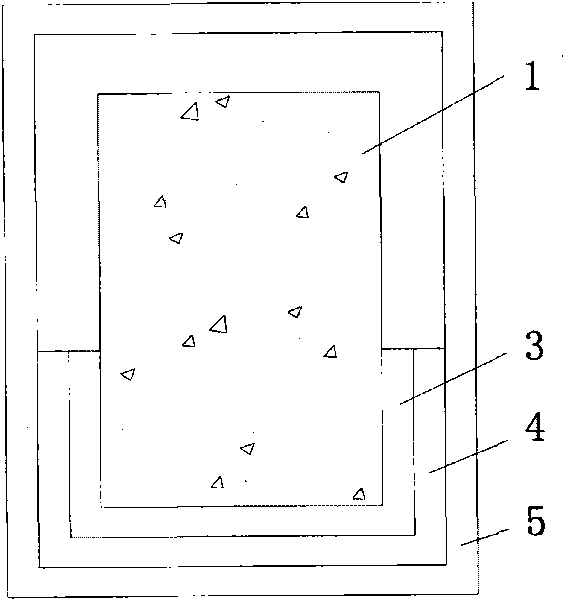

[0062] Concrete specimen 1 was prepared by embedding stainless steel sheet 2 in concrete.

[0063] The size of the concrete (curved beam) is 150×200×1500mm. The tensile longitudinal reinforcement is 2 deformed steel bars with a diameter of 16mm. It is two smooth round steel bars with a diameter of 10mm, and a stainless steel sheet with a size of 30×1300×0.2mm is arranged in the middle of the beam.

[0064] (2) Electroosmotic treatment:

[0065] Net protective layer thickness x d 0.03m; the concrete connected porosity φ is 10%; the gas constant R is 8.3145J / mol / K; the average value T of the initial and final temperature of the electroosmotic treatment of the stainless steel sheet is 298K; the stainless steel mesh and the stainless steel sheet (yin and yang poles The distance L between ) is 0.1m; the voltage U between the stainless steel mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com