Method for remotely monitoring real-time working condition of engineering mechanical vehicles

A construction machinery and remote monitoring technology, applied in the direction of registration/instruction of vehicle operation, time register, registration/instruction, etc., can solve the problems of time and traffic waste, less data volume, misinformation, etc., and reduce management costs , Convenient fault handling, accurate fault analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

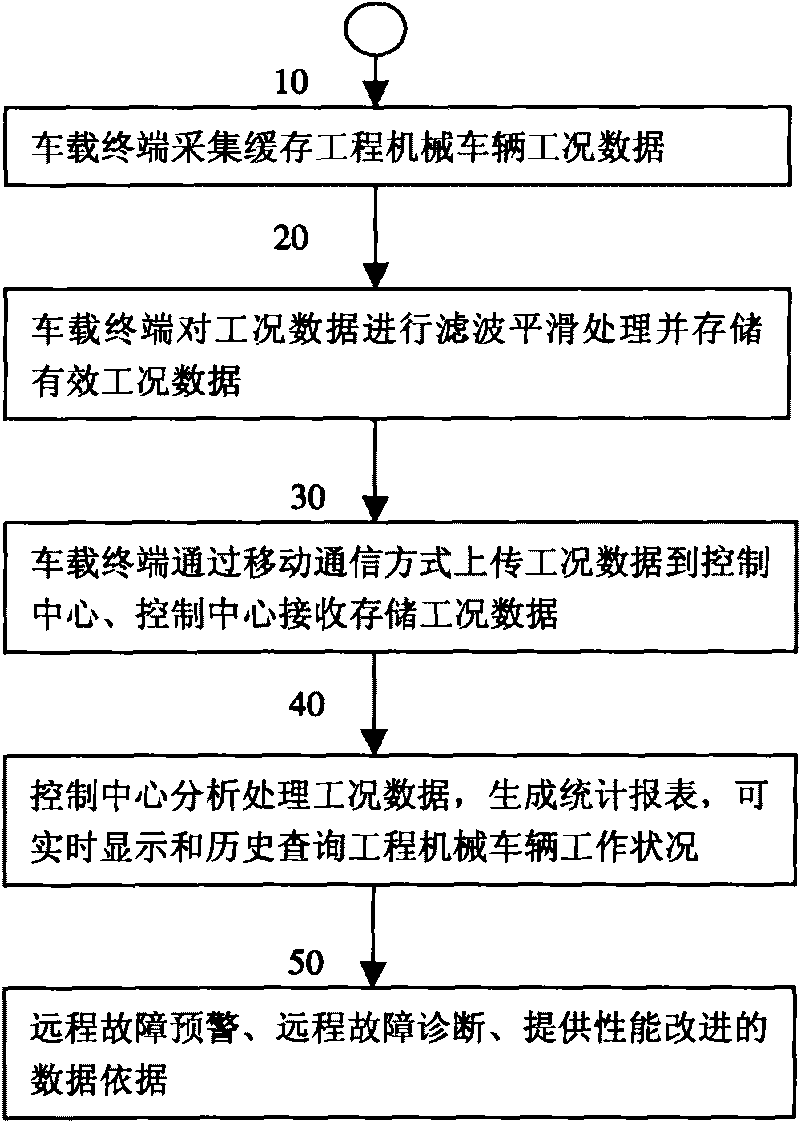

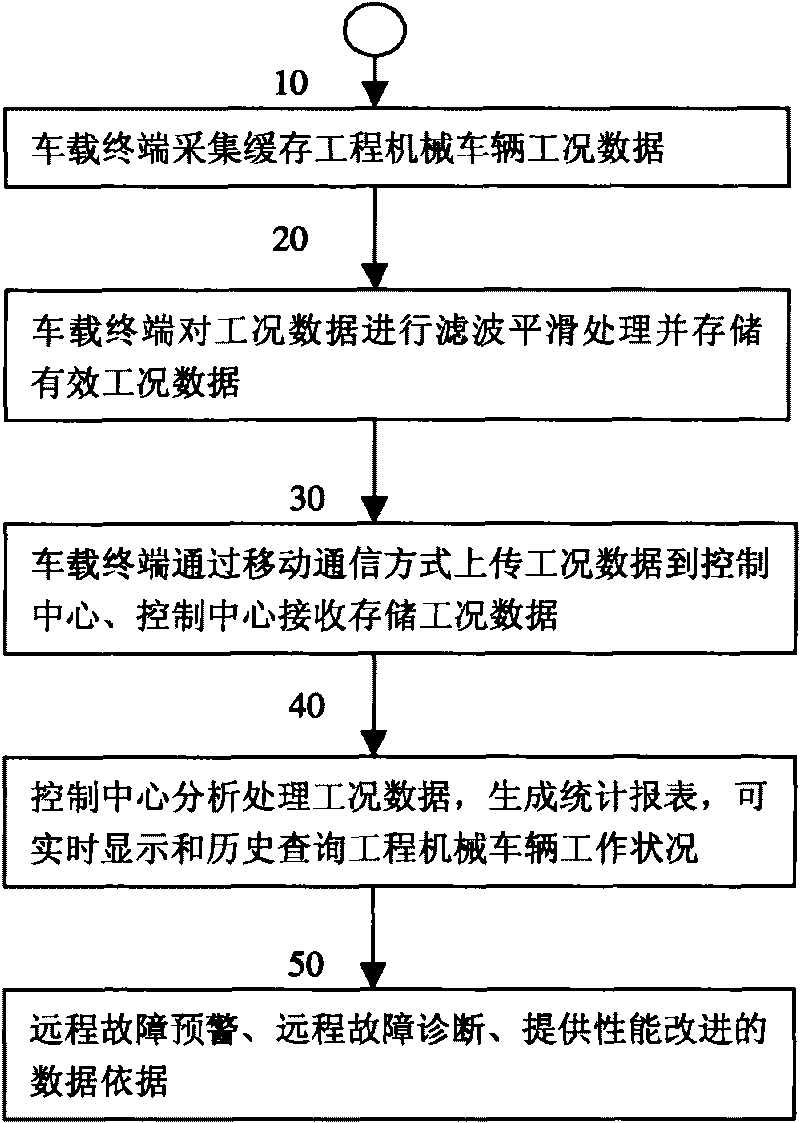

[0023] Referring to the accompanying drawings, a method for remotely monitoring the real-time working conditions of construction machinery vehicles of the present invention includes the following steps:

[0024] Data collection steps: such as figure 1 Shown in the middle frame 10; the working condition data acquisition module of the vehicle-mounted terminal regularly collects various types of working condition data corresponding to construction machinery vehicles, the GPS module of the vehicle-mounted terminal collects GPS data in real time, and the central processing module of the vehicle-mounted terminal collects various types of working conditions regularly collected Condition data and GPS data are temporarily stored in the buffer of the vehicle-mounted terminal; in this data collection step, the timing interval for the vehicle-mounted terminal to collect construction machinery vehicle condition data is 1 second; various types of condition data include water temperature, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com