Laser cutting method

A cutting method, laser technology, applied in the direction of sustainable manufacturing/processing, final product manufacturing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe in detail the features and effects of the present invention, the following preferred embodiments are given below and are described in conjunction with the drawings, wherein:

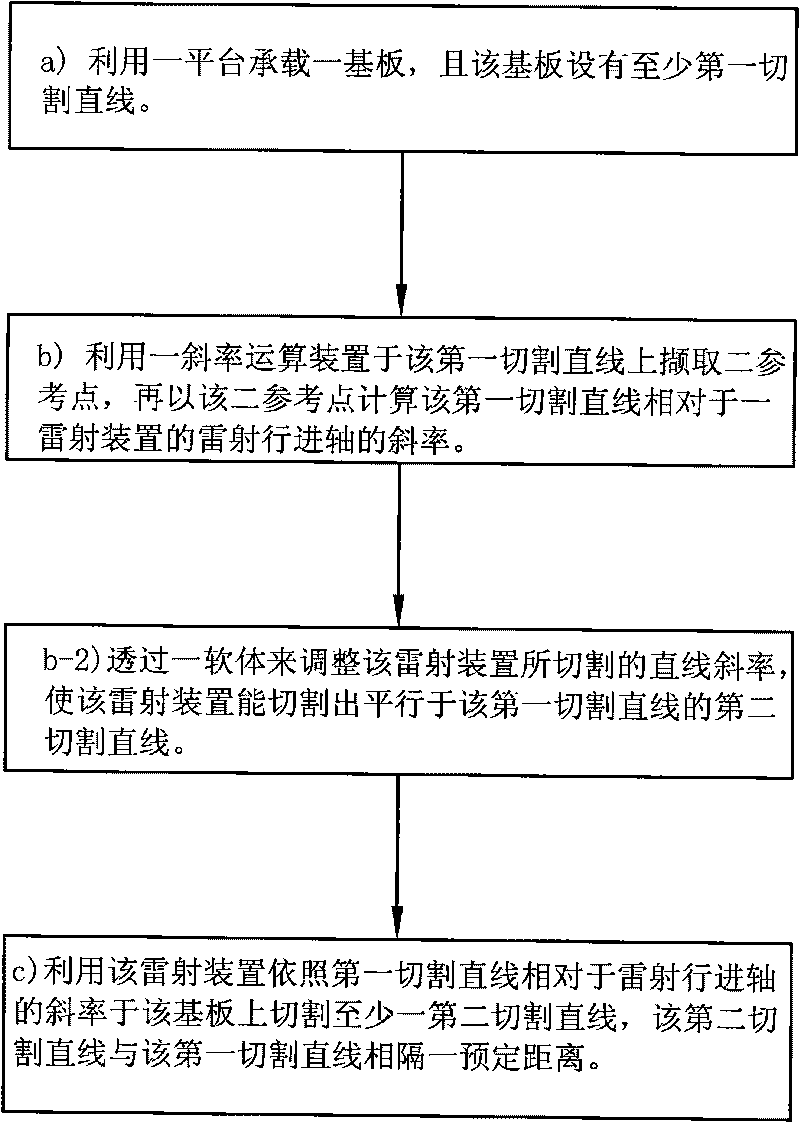

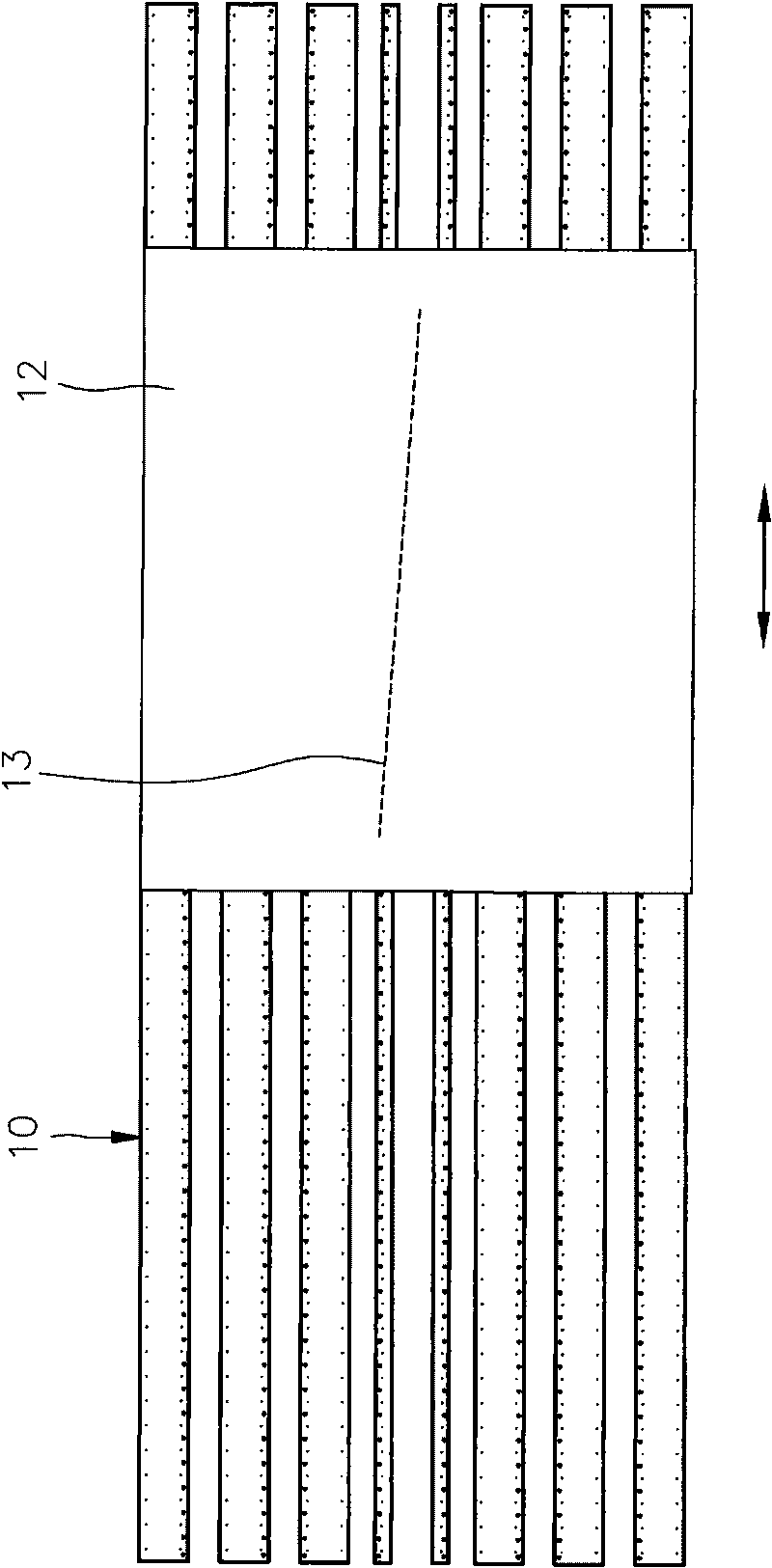

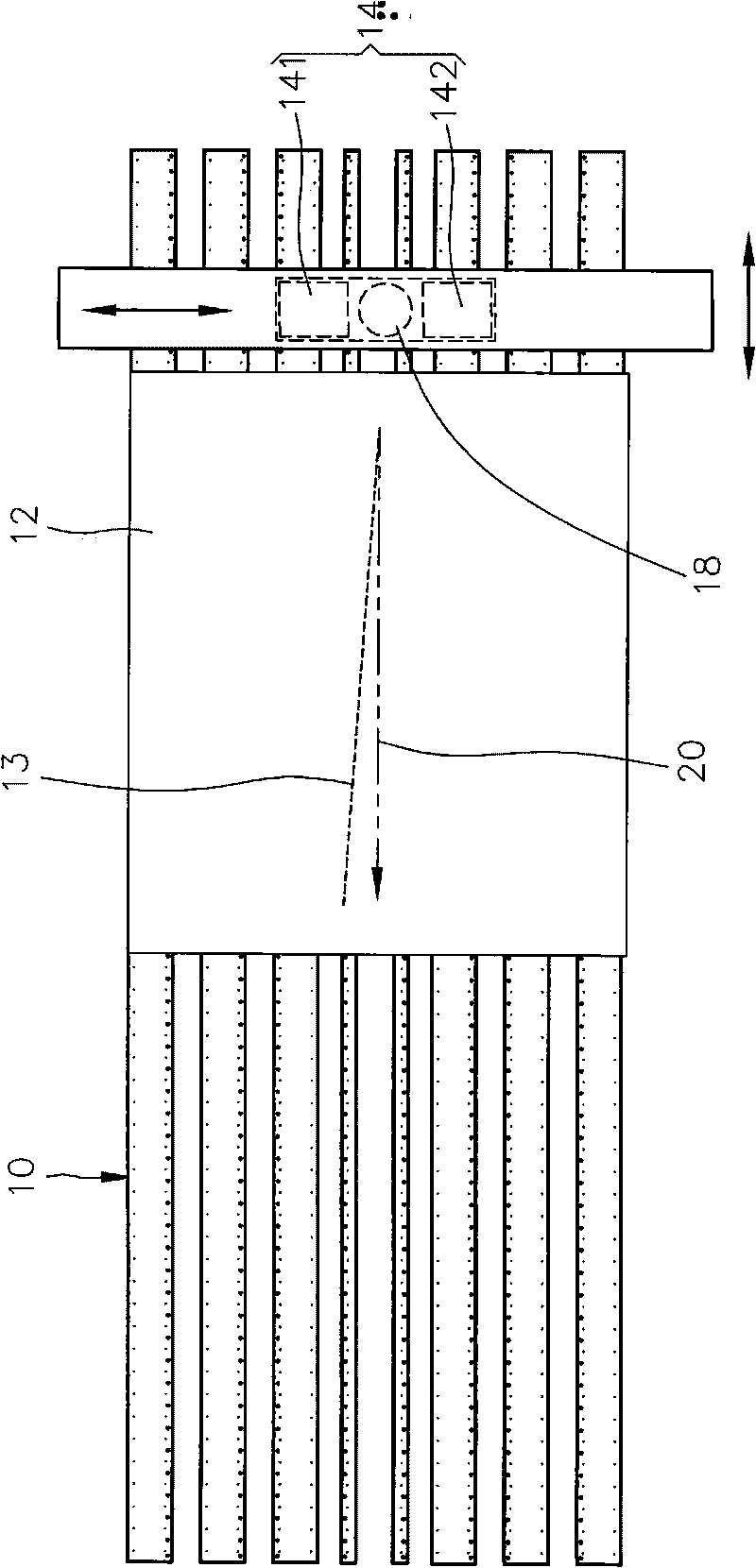

[0016] see Figure 1 to Figure 4 , a laser cutting method provided by the first preferred embodiment of the present invention, which includes the following steps: a) First, please refer to figure 2 , using a platform 10 to carry a substrate 12 , and the substrate 12 is provided with at least one first cutting line 13 . Wherein the platform 10 can be an air floating platform, and the substrate 12 can be a solar substrate; b) please refer to image 3 , use a slope calculation device 14 to capture two reference points on the first cutting line 13, and then use the two reference points to calculate the slope of the first cutting line 13 relative to the laser travel axis 20 of a laser device 18. Wherein, the slope computing device 14 includes an image capturing device 141 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com