Connecting structure of flexile printed circuit board and method for manufacturing same

A connection structure, flexible printing technology, applied in the direction of electrical connection formation of printed components, printed circuit components, electrical connection printed components, etc., can solve problems such as re-opening mold design, achieve stable electrical connections, reduce costs, and avoid time and the effect of waste of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

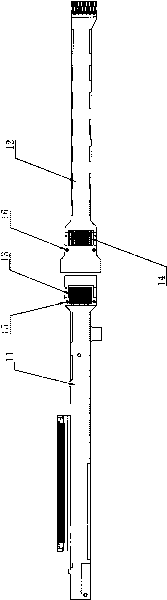

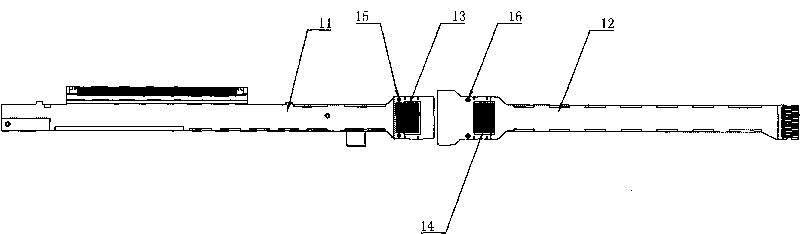

Image

Examples

Embodiment approach

[0027] Preferably, after the step B, visual inspection and tension inspection are also included. The visual inspection here is to check whether the FPC is scratched during the operation process. The main result of the flexible printed circuit board connection is the reference continuity and reliability. Whether the performance is good or not, the tensile inspection standard is generally given according to customer needs. As an implementation manner, the tensile force required by the FPC connection structure may be greater than 200 g / cm.

[0028] In the manufacturing method of the flexible printed circuit board connection structure, the electrical connection between the module FPC and the FPC is connected by ACF, which has good high temperature stability, low thermal expansion coefficient, low moisture absorption, and excellent conductivity; it can be used according to the FPC gold finger Conductive gold balls with different diameters are selected for the Pitch value between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com