Low-cost giant liquid crystal display film and preparation process thereof

A liquid crystal display, low-cost technology, applied in the field of low-cost giant liquid crystal display film and its preparation process, can solve the problems of high cost, affecting the use of film, and insufficient connection of conductive layer, so as to achieve stable electrical connection and improve contact Area and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

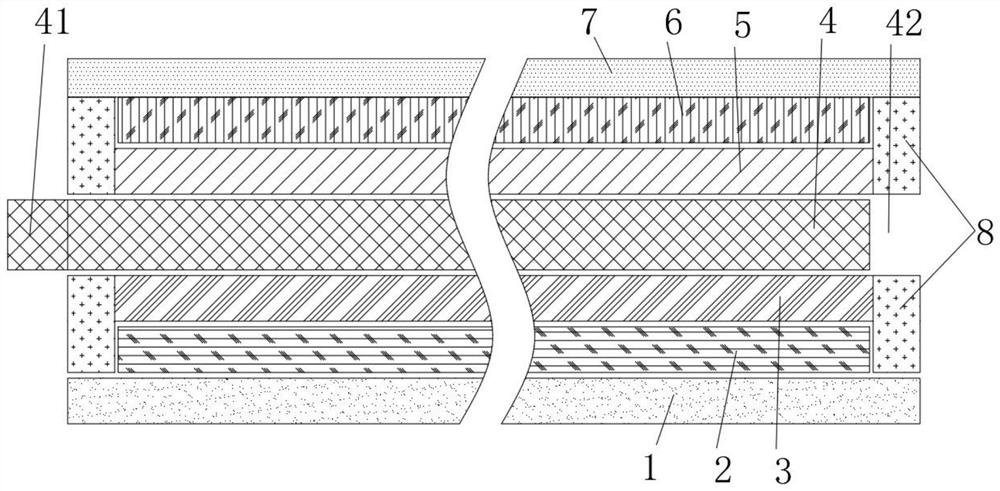

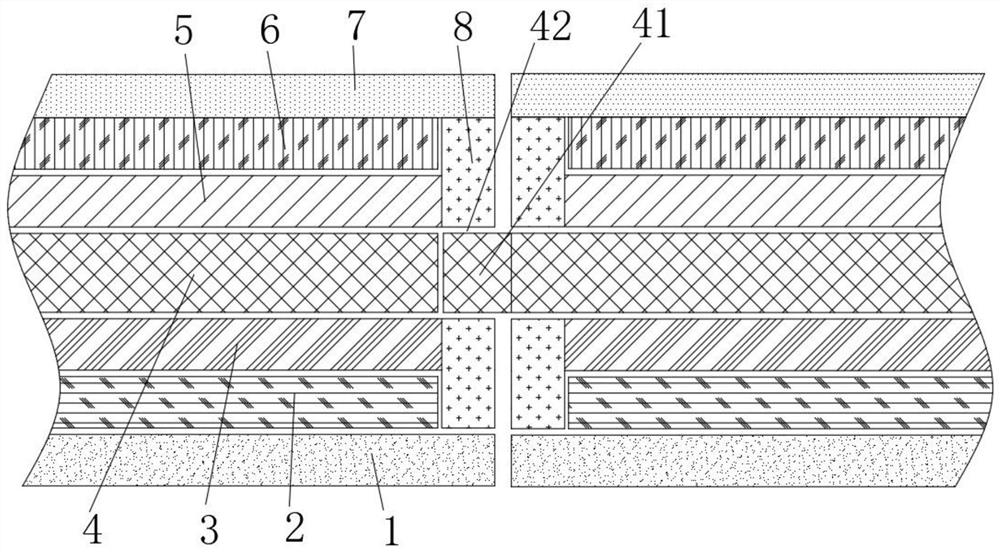

[0029] The present invention provides such as Figure 1-2A low-cost giant liquid crystal display film is shown, including the first light guide film 1, which has the characteristics of ultra-thin, uniform light emission, and multi-color changes. The point light source of LED can be converted into a surface light source through the color light guide film , with high refractive index and light transmittance, the upper surface of the first light guide film 1 is sequentially provided with a first horizontal polarizer 2, a first conductive layer lower film 3, a first cholesteric liquid crystal layer 4, a first conductive The film 5 on the layer, the first vertical polarizer 6 and the first insulating film 7, the first horizontal polarizer 2 and the first vertical polarizer 6 are polarizers, which are made according to the polarization principle of light, and have the function of effectively eliminating glare. Special function, the imaging of liquid crystal display must rely on pola...

Embodiment approach 2

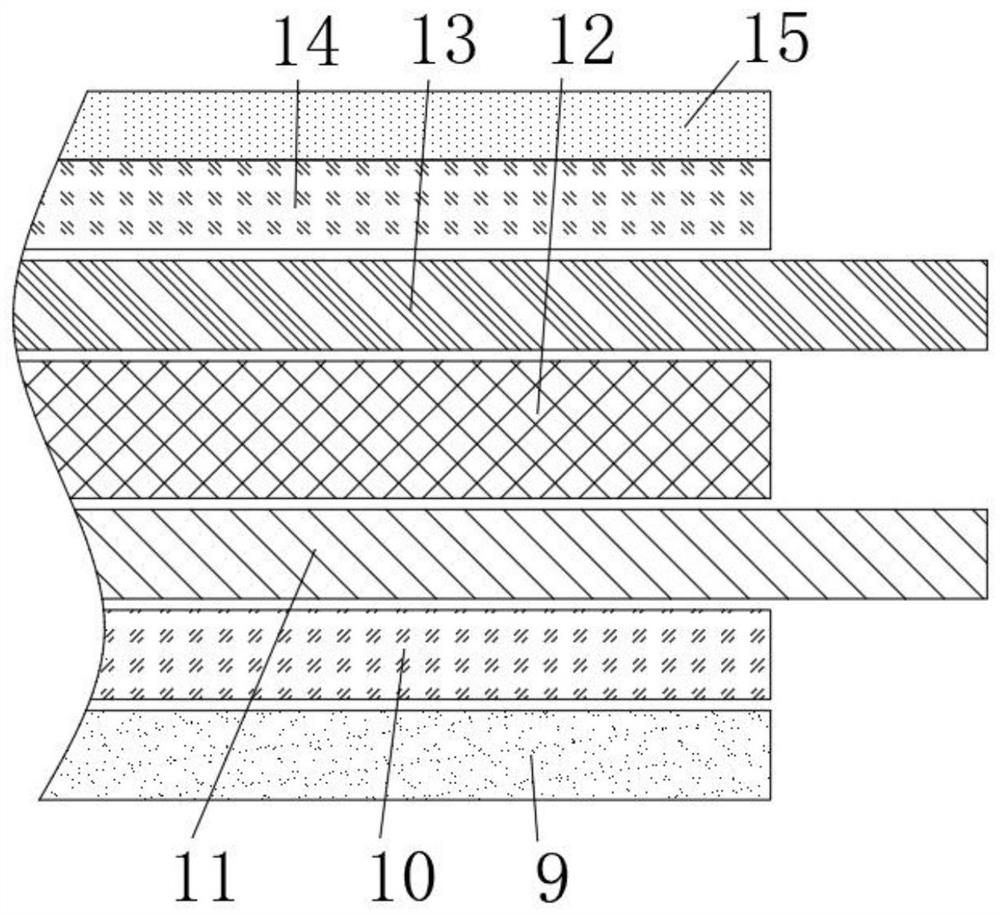

[0035] The present invention provides such as Figure 3-5 A low-cost giant liquid crystal display film shown includes a second light guide film 9 and a third light guide film 91, and the upper surface of the second light guide film 9 is provided with a second horizontal polarizer 10 and a second conductive layer in sequence. The lower film 11, the second cholesteric liquid crystal layer 12, the upper film 13 of the second conductive layer, the second vertical polarizer 14 and the second insulating film 15, the second light guide film 9, the second horizontal polarizer 10, the second The sides of the lower film 11 of the conductive layer, the second cholesteric liquid crystal layer 12, the upper film 13 of the second conductive layer, the second vertical polarizer 14 and the second insulating film 15 are all connected by OCA optical glue. , the second light guide film 9, the second horizontal polarizer 10, the lower film 11 of the second conductive layer, the second cholesteric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com