Conductive adhesive and application thereof

A technology of conductive adhesive and conductive ball, applied in the field of conductive adhesive, can solve the problems of poor fixation, inability to connect electronic components, etc., to achieve the effect of firm electrical connection, realization of product characteristics, and simplified formula process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

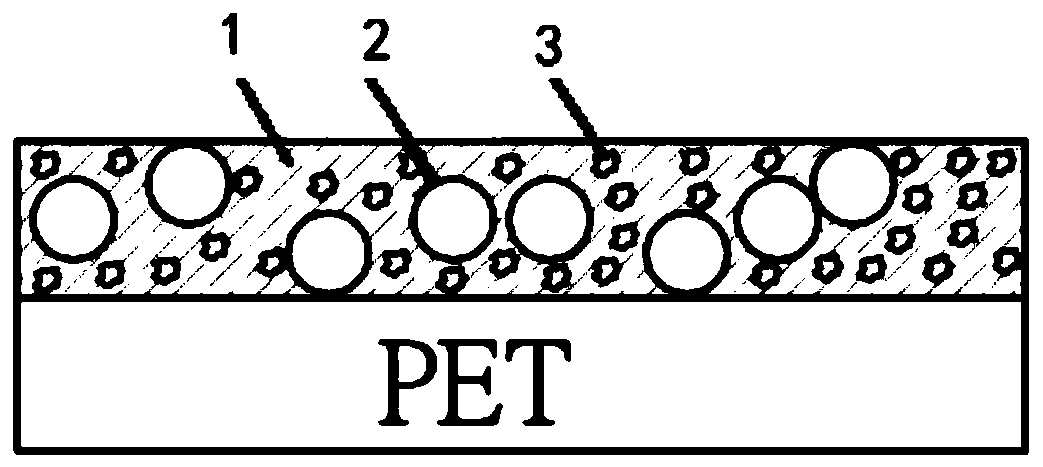

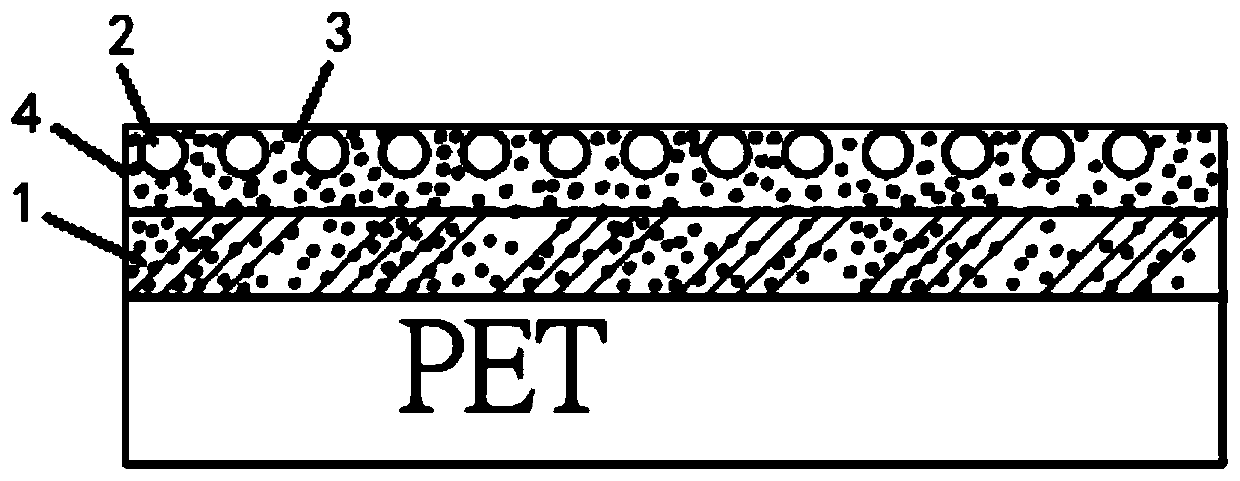

[0036] In order to achieve the purpose of the present invention, in some embodiments of a conductive adhesive and its application, such as figure 1 As shown, a conductive adhesive includes: an adhesive layer 1 , a plurality of conductive balls 2 distributed in the adhesive layer 1 , and a plurality of low-melting alloy balls / powders 3 scattered in the adhesive layer 1 .

[0037] The invention discloses a conductive adhesive, in which a plurality of low melting point alloy balls / powders are scattered and arranged in the adhesive layer 1, when electronic components are connected to each other, the low melting point alloy balls / powders 3 melt at high temperature, so that the electronic components are electrically connected Stronger, no misalignment. At the same time, the one-time mixing method of conductive ball 2, low melting point alloy ball / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com