Numerically controlled lathe cutting tool compensation system and numerically controlled lathe cutting tool compensation method

A technology for CNC machine tools and tool compensation, applied in the field of CNC machine tools, can solve the problems of multiple tool compensation, affecting the machining accuracy of multi-spindle CNC machine tools, and achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

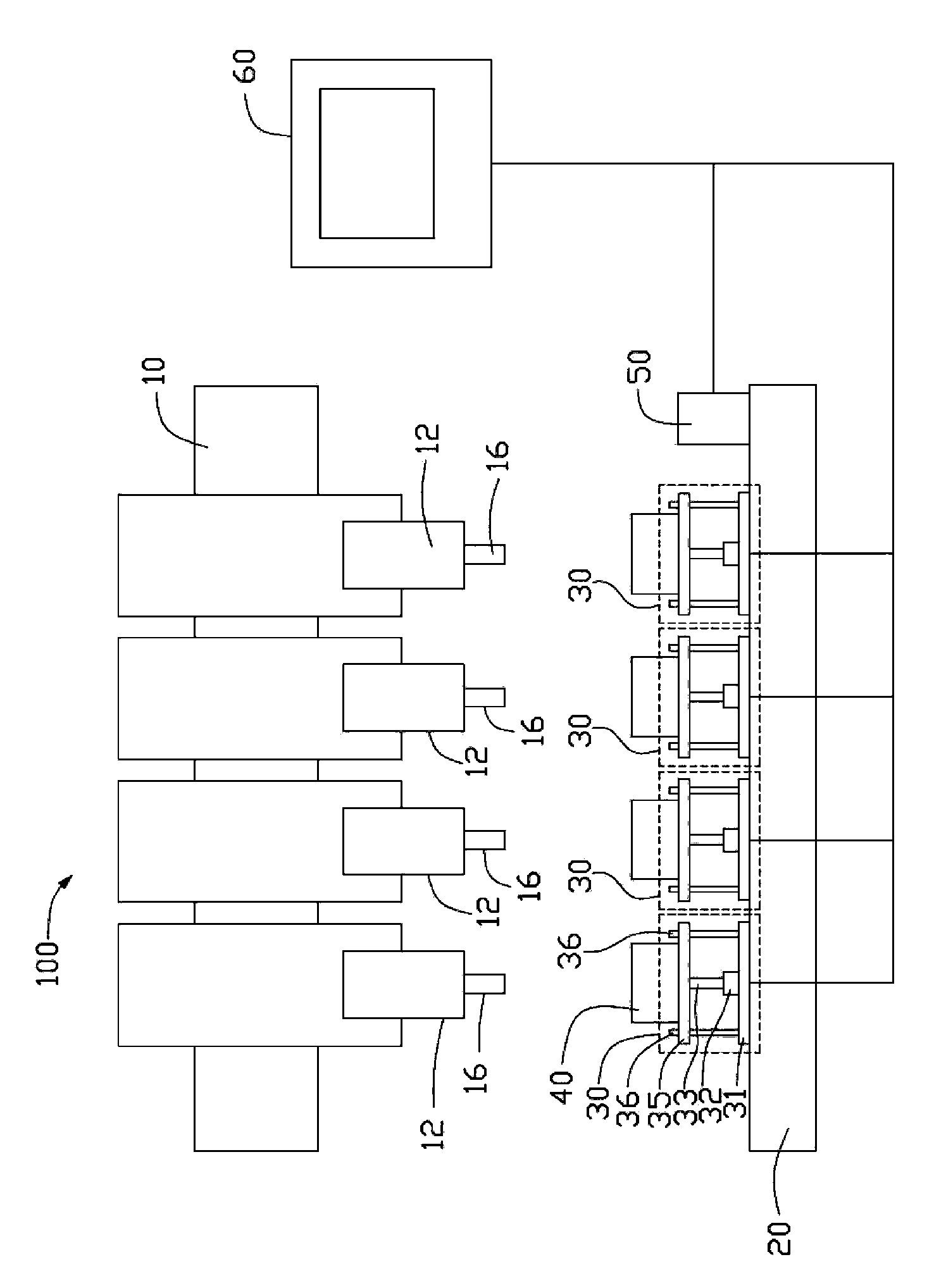

[0014] Please refer to figure 1 , the CNC machine tool tool compensation system of the present invention is used to compensate the wear of multiple cutters 16 on a multi-spindle CNC machine tool 100, and its preferred embodiment includes a body 10 provided with four spindles 12, a working platform 20, Four compensating devices 30 , a tool pairing instrument 50 and a control system 60 are arranged on the working platform 20 . Wherein, each cutter 16 is provided on a corresponding spindle 12 , and the four compensating devices 30 are respectively used to compensate the wear of the four cutters 16 . In this embodiment, the tool setting instrument 50 is connected to the control system 60 , which may be a contact tool setting instrument or a non-contact tool setting instrument. In other embodiments, the specific numbers of the spindle 12 , the tool 16 and the compensation device 30 can be adjusted according to the actual situation.

[0015] Each compensation device 30 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com