Plunger piston pair

A plunger pair and plunger technology, applied in the field of ultra-high pressure hydraulic components, can solve the problems of low volume efficiency of plunger pair, increase in axial size, heavy weight of plunger pair, etc., achieve compact structure and reduce oil valve body , The effect of eliminating the installation gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

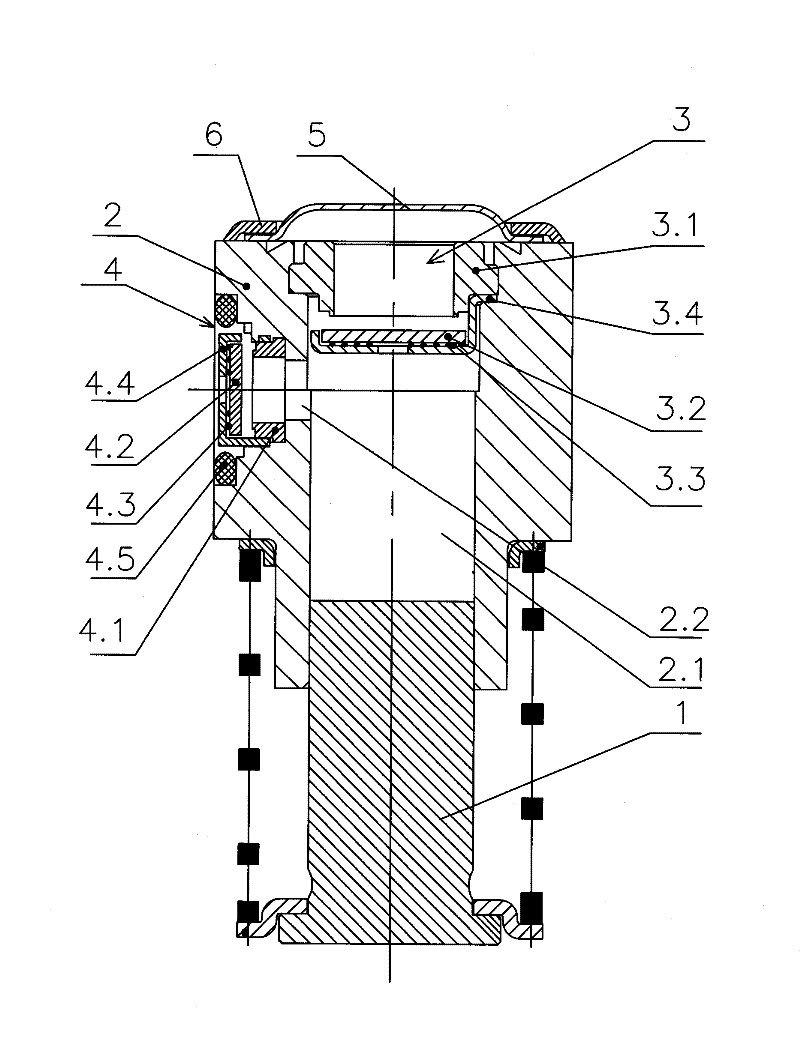

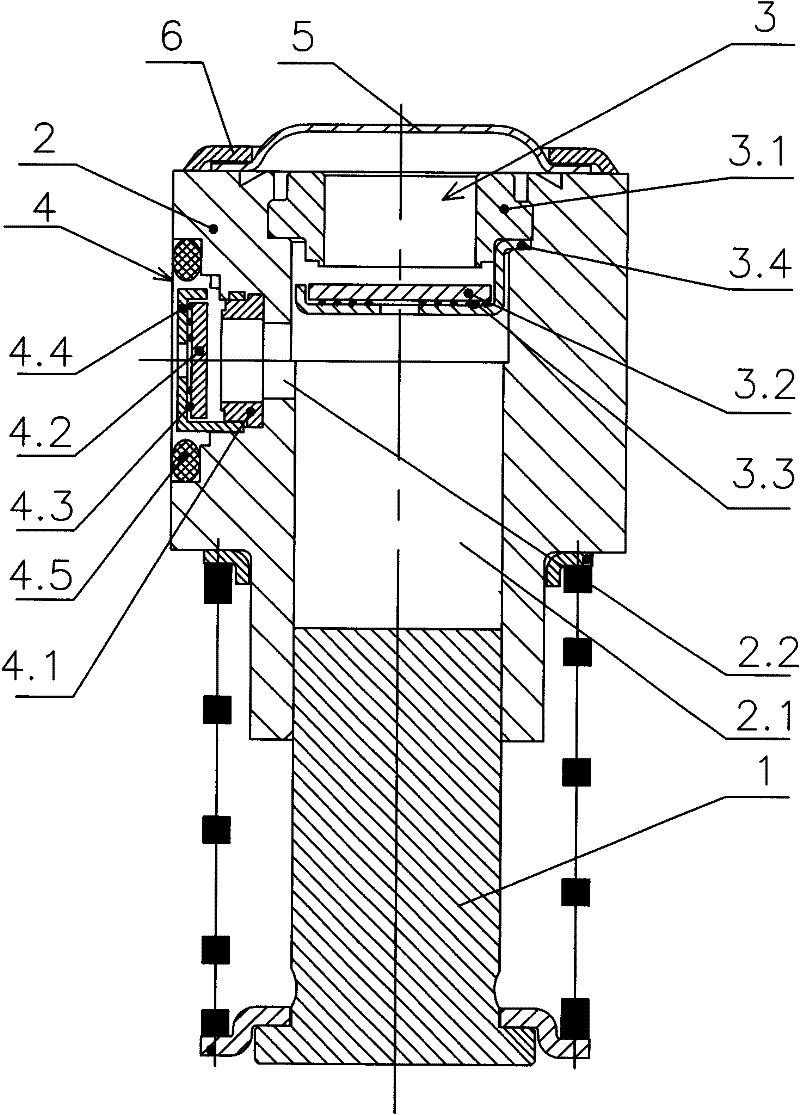

[0019] As shown in the figure, the plunger pair of the present invention includes a plunger 1, a plunger sleeve 2 with an oil chamber 2.1, an oil inlet valve 3 and an oil outlet valve 4; the oil inlet valve 3 is located on the plunger sleeve 2 At the opening of the oil chamber 2.1, the plunger sleeve 2 is provided with a radial through hole 2.2 communicating with the oil chamber 2.1, and the oil outlet valve 4 is arranged in the through hole 2.2.

[0020] The oil outlet valve 4 sequentially includes a first valve seat 4.1, a first valve plate 4.2, a first return spring 4.3, and a first fixed cover 4.4 from inside to outside; the first valve seat 4.1 is tightly fitted in the through hole 2.2 , the through hole 2.2 is a multi-stage stepped hole, the first valve seat 4.1 and the first fixed cover 4.4 are tightly fitted on the steps of the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com