Combined bearing

A technology of combining bearings and components, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as inability to meet drilling equipment, poor bearing lubrication performance, and large weight of closed cages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

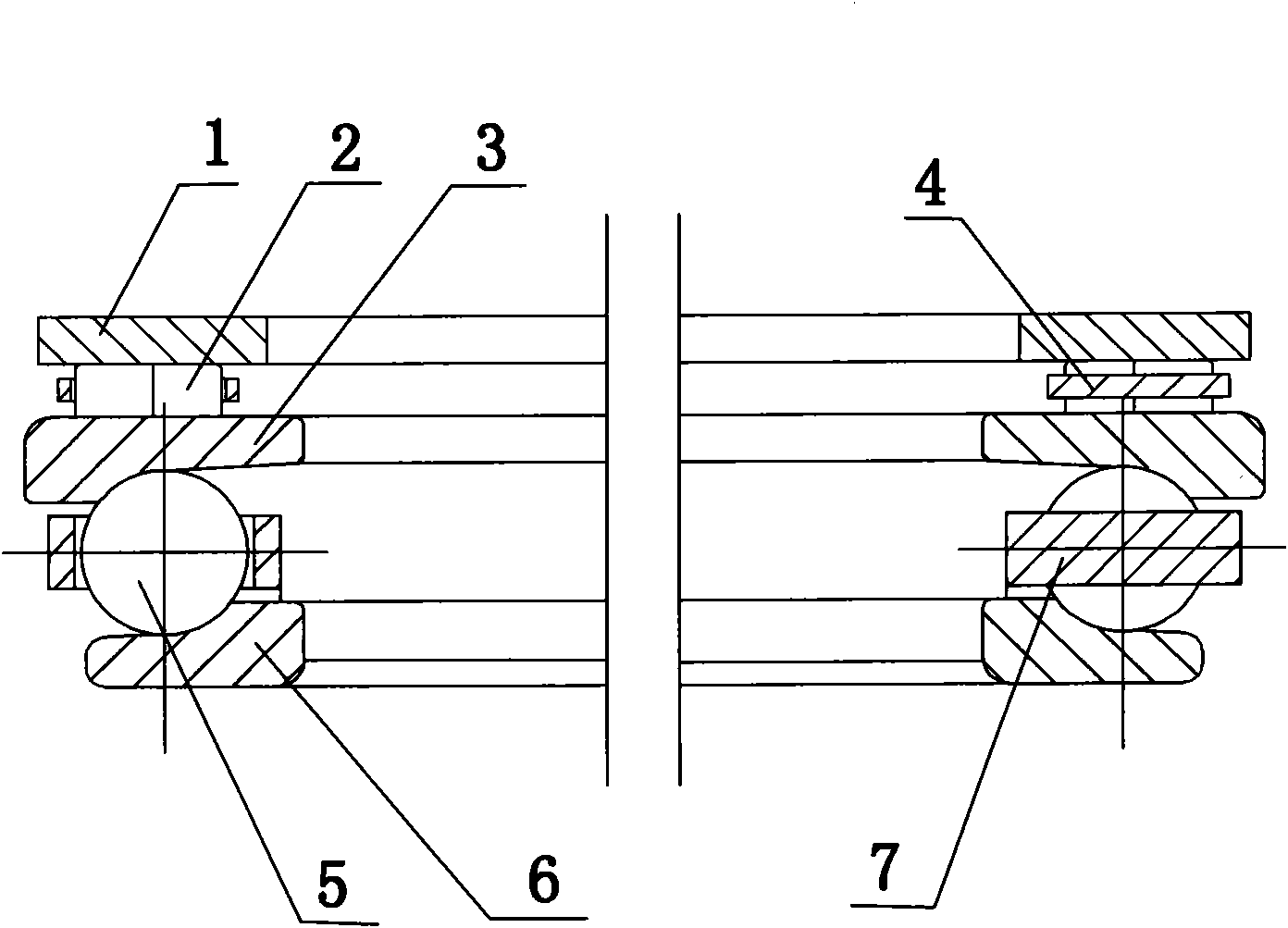

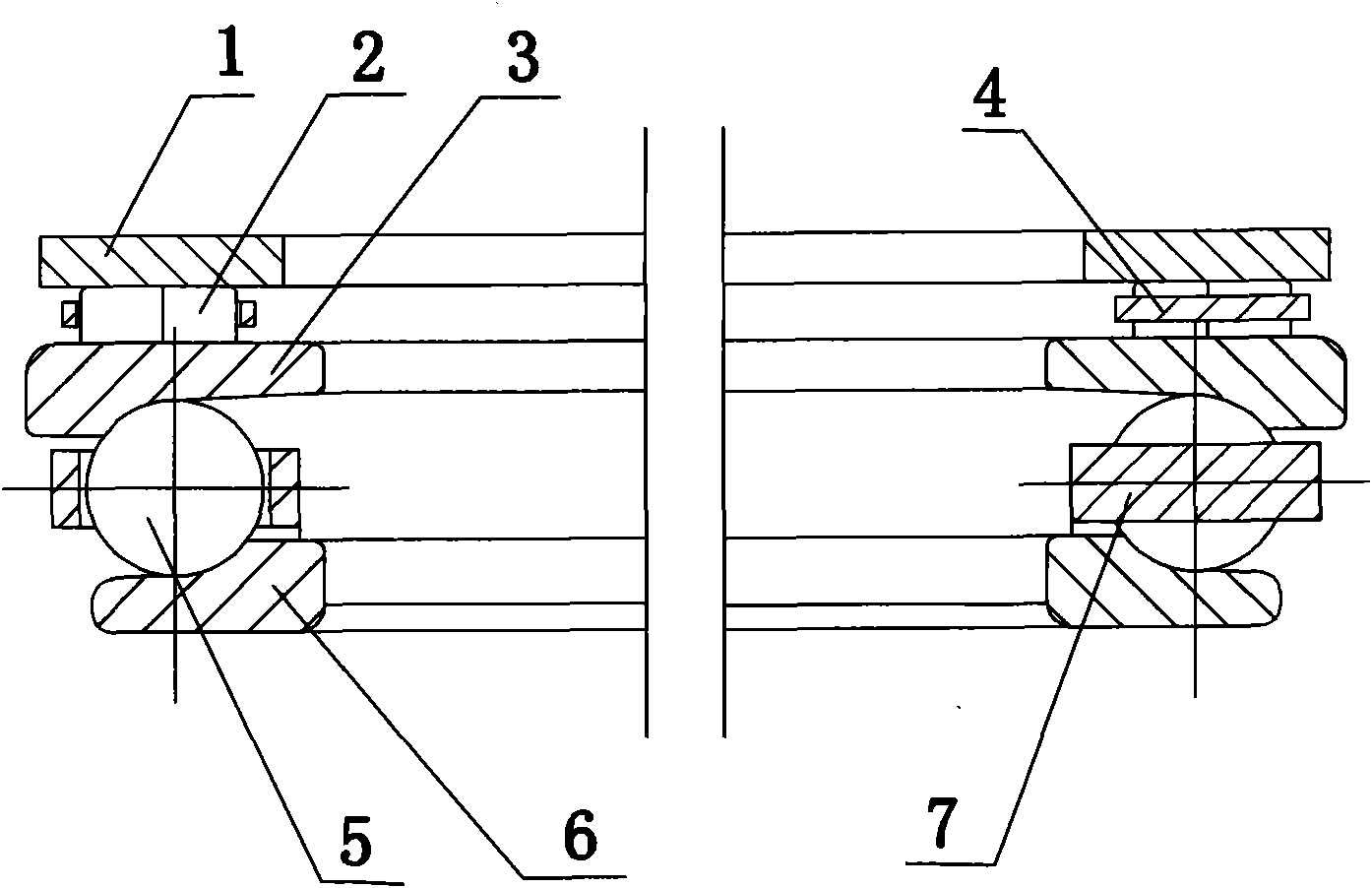

[0007] Such as figure 1 The combined bearing shown includes two sets of rolling element assemblies stacked one above the other. Among them, the first set of rolling element components includes the upper upper shaft ring 1, the lower middle shaft ring 3, and the cylindrical roller 2 between the upper shaft ring 1 and the middle shaft ring 3; the cylindrical roller 2 is formed by the first cage 4 limited position. The second set of rolling element components includes the central shaft ring 3, the lowermost race 6, and the steel ball roller 5 between the central shaft ring 3 and the race 6; the position of the steel ball roller 5 is defined by the second cage 7 . In addition, in a preferred manner, the diameter of the seat ring 6 is smaller than the diameters of the upper shaft ring 1 and the middle shaft ring 3 . The middle shaft ring 3 and the seat ring 6 are correspondingly provided with raceways for the steel ball rollers 5 . And in a preferred manner, the first cage 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com