Automatic recovery and fill system of refrigeration system

A refrigeration system and automatic recovery technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as low efficiency of the system, lack of oil in the compressor, wear and tear of the compressor, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

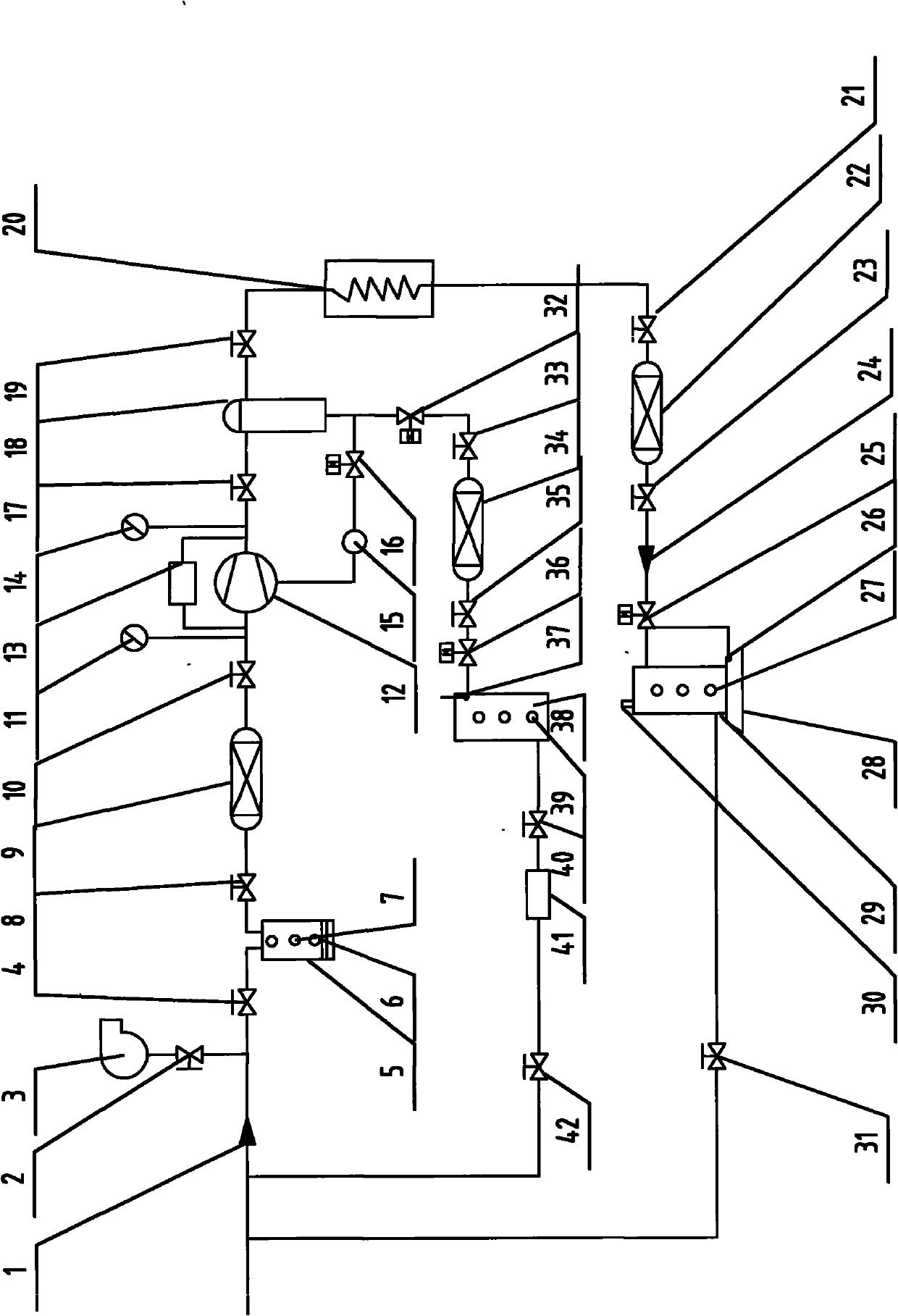

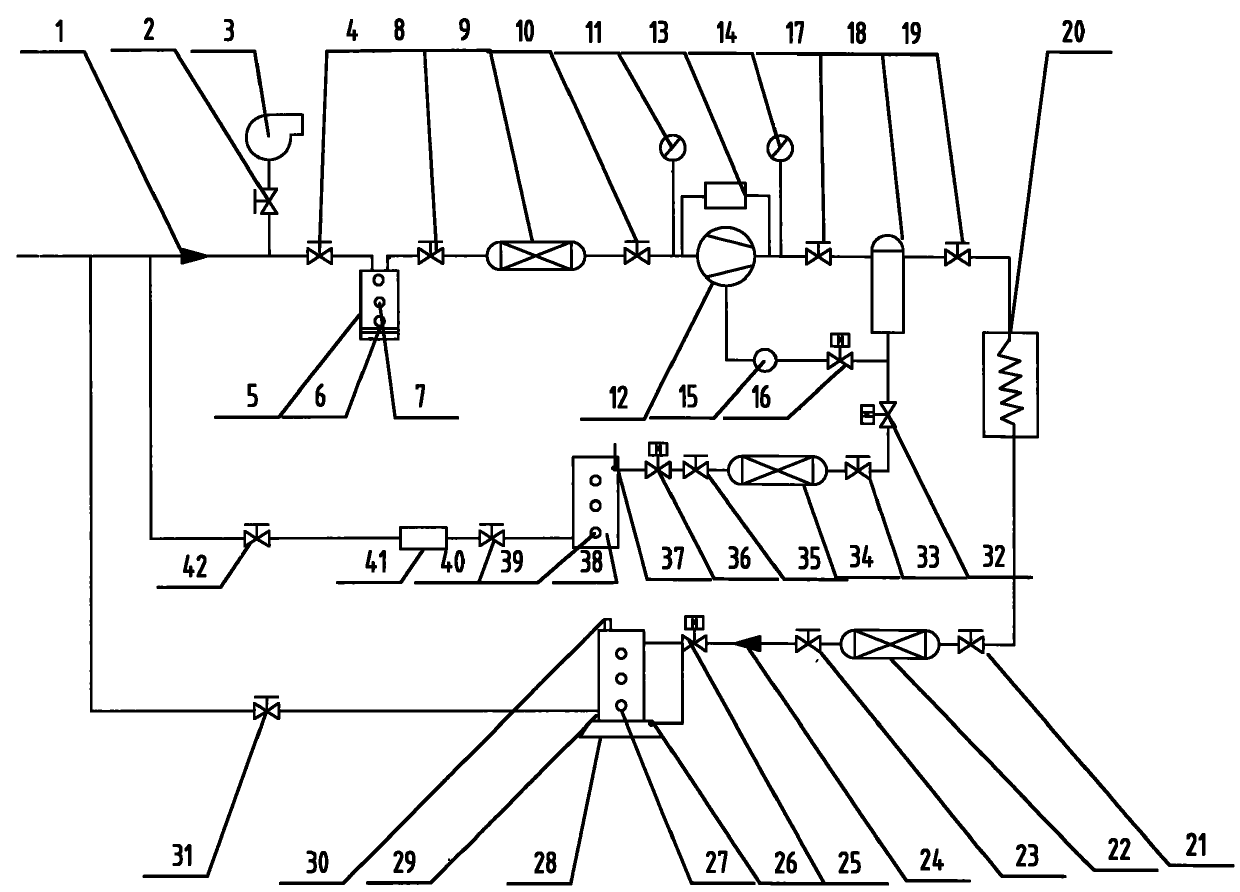

[0019] The present invention will be further described below in conjunction with accompanying drawing, as figure 1 As shown, a refrigerant automatic recovery and charging system of a refrigeration system includes a refrigerant recovery and charging device, a vacuum device, and the vacuum device includes a manual shut-off valve A2 and a vacuum pump 3; The agent recovery device includes a gas-liquid separation evaporation tank 5, a compressor 12, an oil separator 18, a condenser 20, and a liquid storage tank 29. The front end of the gas-liquid separation evaporation tank 5 is connected with a manual stop valve B4 and a one-way valve A1 , the rear end is connected in sequence with manual shut-off valve C8, suction filter 9, manual shut-off valve D10, low pressure gauge 11 and compressor 12, high and low pressure switch 13 is connected in parallel with compressor 12, and the outlet end of compressor 12 is connected with high pressure in turn Table 14. Manual cut-off valve E17 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com