Automatic cleaning net changing, washing and drying device adopting real-time embedded control

A technology of embedded control and drying device, which is applied in the direction of cleaning method using liquid, cleaning method using gas flow, drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

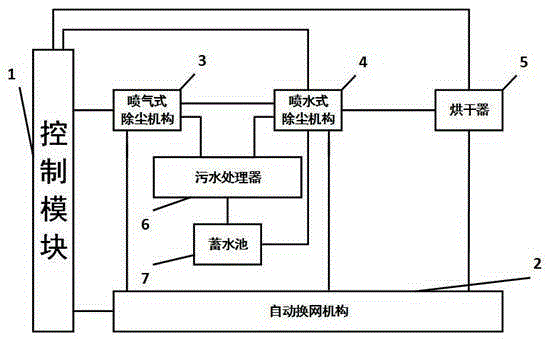

[0035] Embodiment 1: as Figure 1-10 As shown, a real-time embedded control cleaning net automatic washing and drying device includes a control module 1, an automatic net changing mechanism 2, a jet dust removal mechanism 3, a water spray dust removal mechanism 4, a dryer 5, and a sewage processor 6. Reservoir 7; the jet dedusting mechanism 3 is connected with the water spray dedusting mechanism 4, the water spray dedusting mechanism 4 is connected with the dryer 5, and the sewage processor 6 is respectively connected with the jet dedusting mechanism 3, water spray Type dust removal mechanism 4 and reservoir 7 are connected, reservoir 7 is connected with water spray type dust removal mechanism 4, automatic screen changing mechanism 2 is respectively connected with jet type dust removal mechanism 3, water spray type dust removal mechanism 4, dryer 5, The control module 1 is connected with the automatic screen changing mechanism 2 , the jet dust removal mechanism 3 , the water s...

Embodiment 2

[0036] Example 2, such as Figure 1-10 As shown, a real-time embedded control cleaning net automatic washing and drying device, this embodiment is the same as Embodiment 1, wherein:

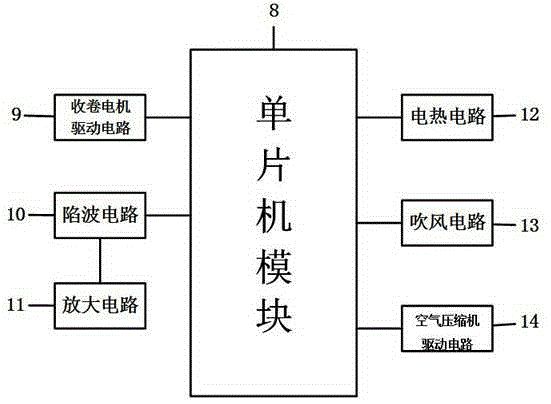

[0037] Described control module 1 comprises single-chip microcomputer module 8, winding motor driving circuit 9, trap circuit 10, amplifying circuit 11, electric heating circuit 12, blower circuit 13, air compressor driving circuit 14; Wherein single-chip microcomputer module 8 is connected with winding motor respectively The drive circuit 9 , the trap circuit 10 , the electric heating circuit 12 , the blower circuit 13 , and the air compressor drive circuit 14 are connected, and the amplifier circuit 11 is connected to the trap circuit 10 .

Embodiment 3

[0038] Example 3, such as Figure 1-10 As shown, a real-time embedded control cleaning net automatic washing and drying device, this embodiment is the same as embodiment 2, wherein:

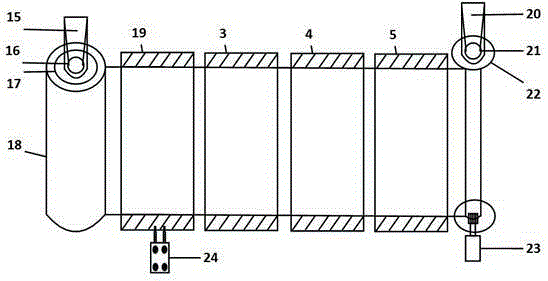

[0039] The automatic net changing mechanism 2 includes a support frame I15, a transmission wheel I16, a discharge rack 17, a cleaning net reel 18, a working window 19, a support frame II20, a transmission wheel II21, a roller 22, a winding motor 23, and a differential pressure sensor 24; wherein the transmission wheel I16 is set on the support frame I15 by using its hollow internal structure, the discharge frame 17 is fixed on the transmission wheel I16, the cleaning net reel 18 is placed on the surface of the discharge frame 17, and the cleaning net is extended from one end of the cleaning net reel 18 Pass through the working window 19, the air jet dedusting mechanism 3, the water jet dedusting mechanism 4, and the dryer 5 to reach the recycling device on the other side in turn. The working wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com