High alloy wear-resistant double-layer composite straight pipe used for concrete pump truck

A concrete pump truck, double-layer composite technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of increasing costs and high import prices, reducing the number of replacements, improving service life and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

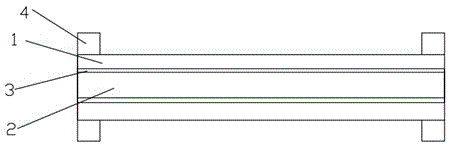

[0018] Such as figure 1 As shown, a high-alloy wear-resistant double-layer composite straight pipe for a concrete pump truck includes an outer pipe 1, an inner pipe 2 and a shock-absorbing material 3, the inner pipe 2 is pushed into the outer pipe 1, and the outer pipe A shock-absorbing material 3 is arranged between 1 and the inner tube 2, and the material used for the shock-absorbing material is one or more of EVA, PE, CR, PU foam, and PORON.

[0019] The outer tube 1 and the inner tube 2 are provided with a flange 4 on the edge, and the size of the outer tube is completely matched without any gap after being inserted into the flange.

[0020] The outer tube 1 is made of No. 45 or No. 20 steel, and there is no welding between the outer tube 1 and the inner tube 2, which can be reused.

[0021] The outer tube 2 is cast from a high chromium alloy with other alloying elements, mainly composed of 18% ferrochrome, 4.5% nickel, 6.5% molybdenum, and 2.0-2.5% carbon and other rare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com