Heating element and liquid container provided with such a heating element

A technology of heating elements and conductive elements, which is applied in the direction of electric heating devices, electrical elements, ohmic resistance heating, etc., and can solve problems such as laborious and time-consuming production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

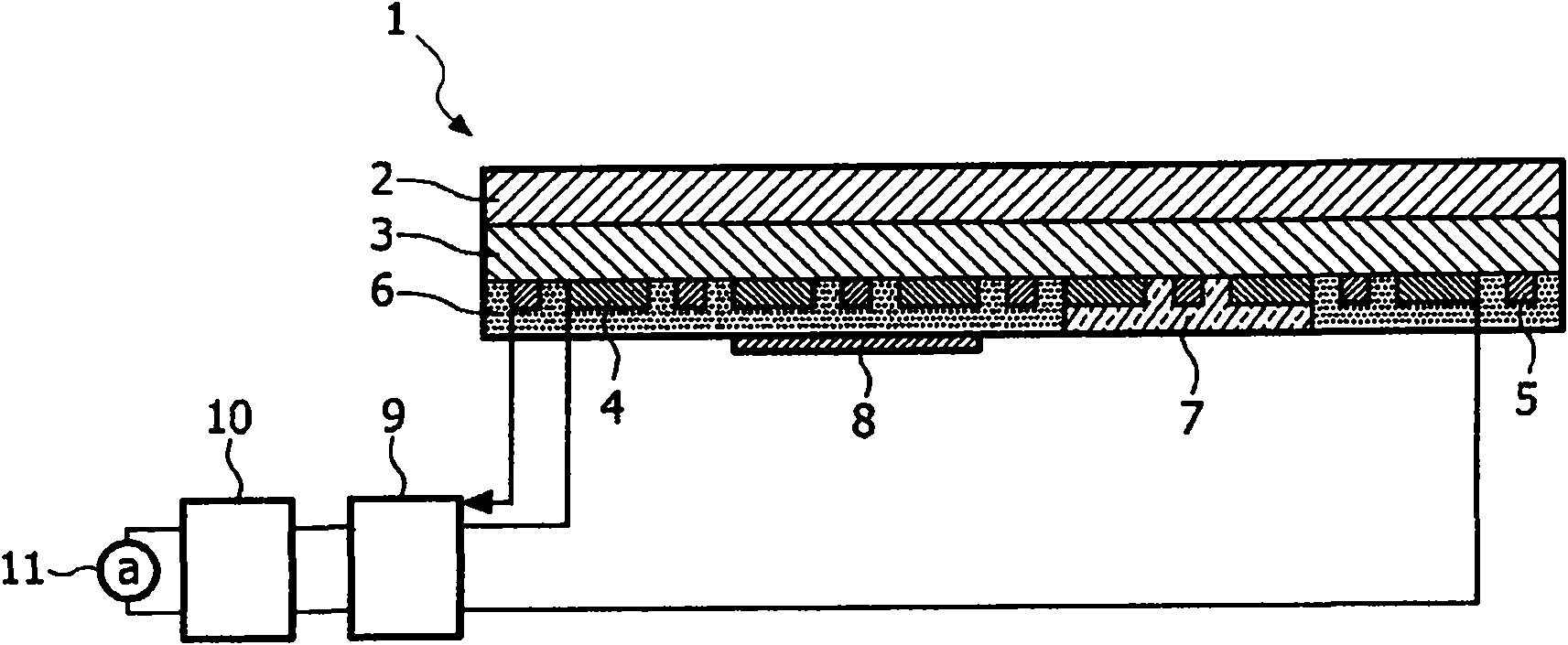

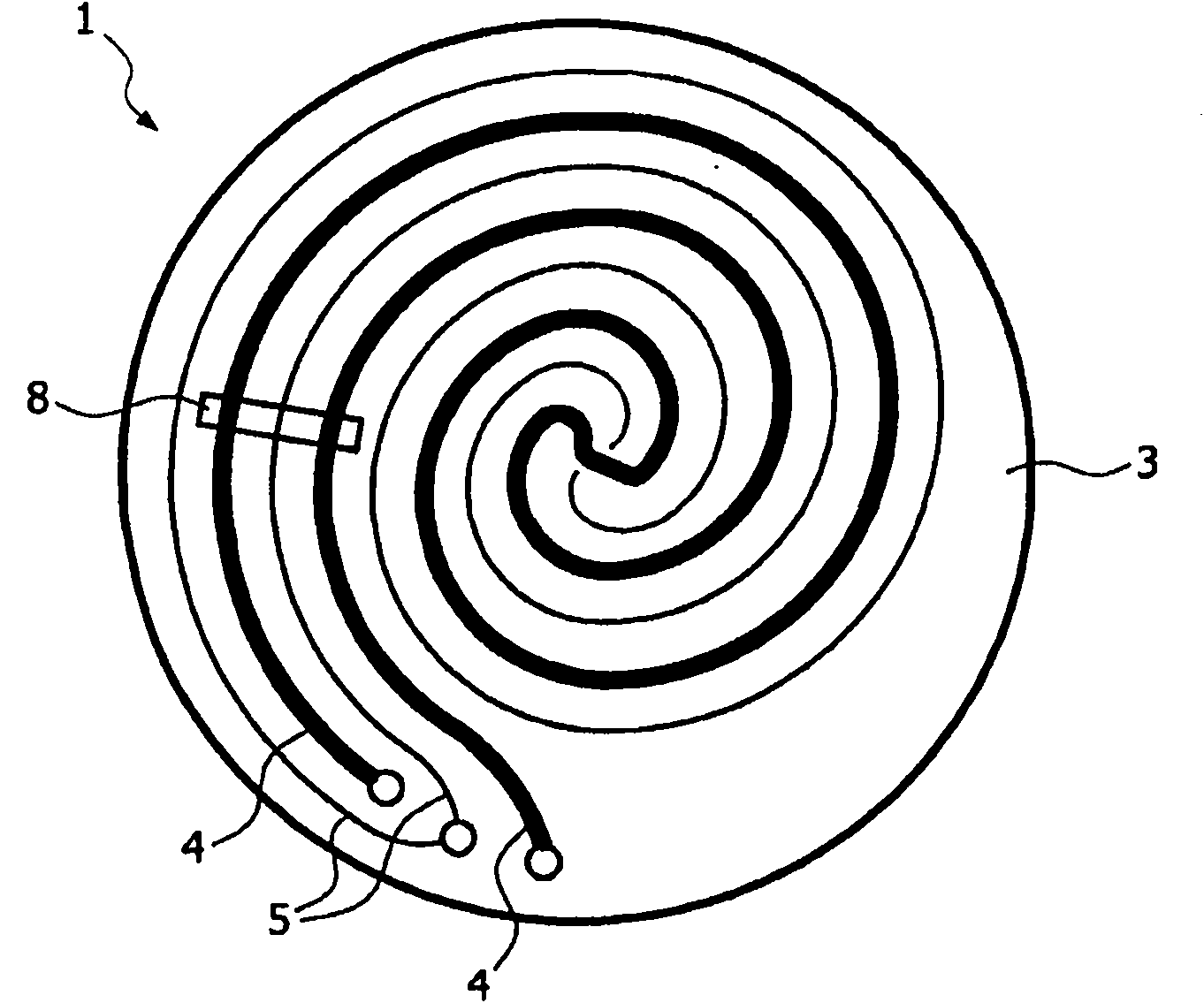

[0030] figure 1 A cross-section of a heating element 1 according to the invention is shown. The heating element 1 comprises a heating plate 2 made of ferritic chromium steel with a chromium content of 18% by weight for heating. Another suitable metal or ceramic carrier can also be applied, such as mild steel, copper, titanium, SiN, Al 2 o 3 etc. A first dielectric enamel layer 3 is arranged on the heating plate 2 . The first enamel layer 3 has an enamel composition substantially according to column HT of Table 1 . The heating tracks 4 and the sensor tracks 5 running parallel to the heating tracks 4 are arranged in an essentially spiral pattern on the first, relatively electrically insulating enamel layer 3 , wherein the distance between these tracks amounts to approximately 500 μm. Preferably, the heating track 4 and the sensor track 5 are made of the same material, more preferably silver, copper or an alloy of these or other metals, in order to simplify and speed up the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com