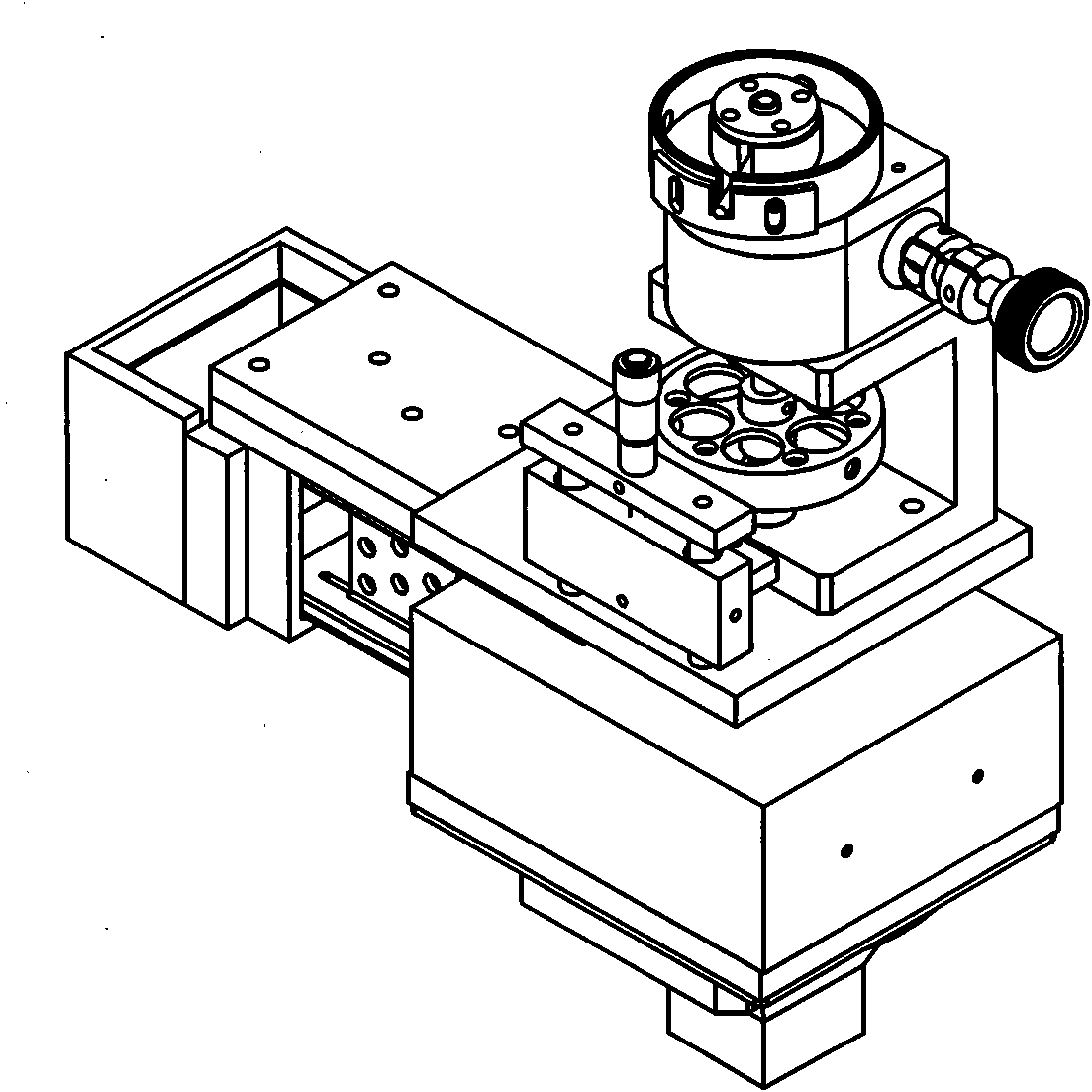

Dismounting-welding integrated hot air head

A technology of wind head and hot air duct, applied in fluid heaters, welding equipment, air heaters, etc., can solve problems such as difficulty in maintaining straightness and service life, inability of tuyere 204 to rotate synchronously, affecting processing quality and production efficiency, etc. , to achieve the effect of small mutual influence, not easy to deform, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

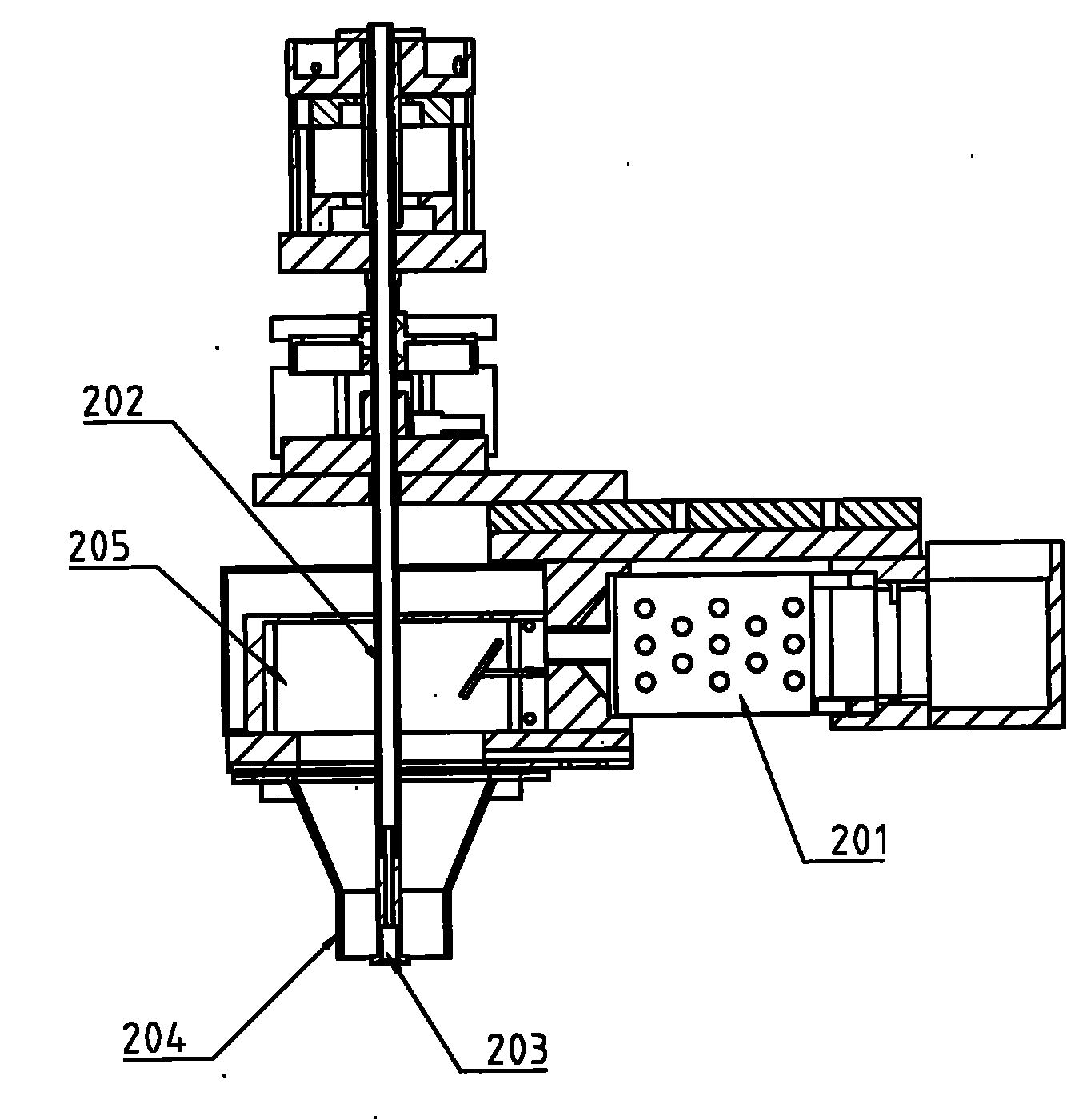

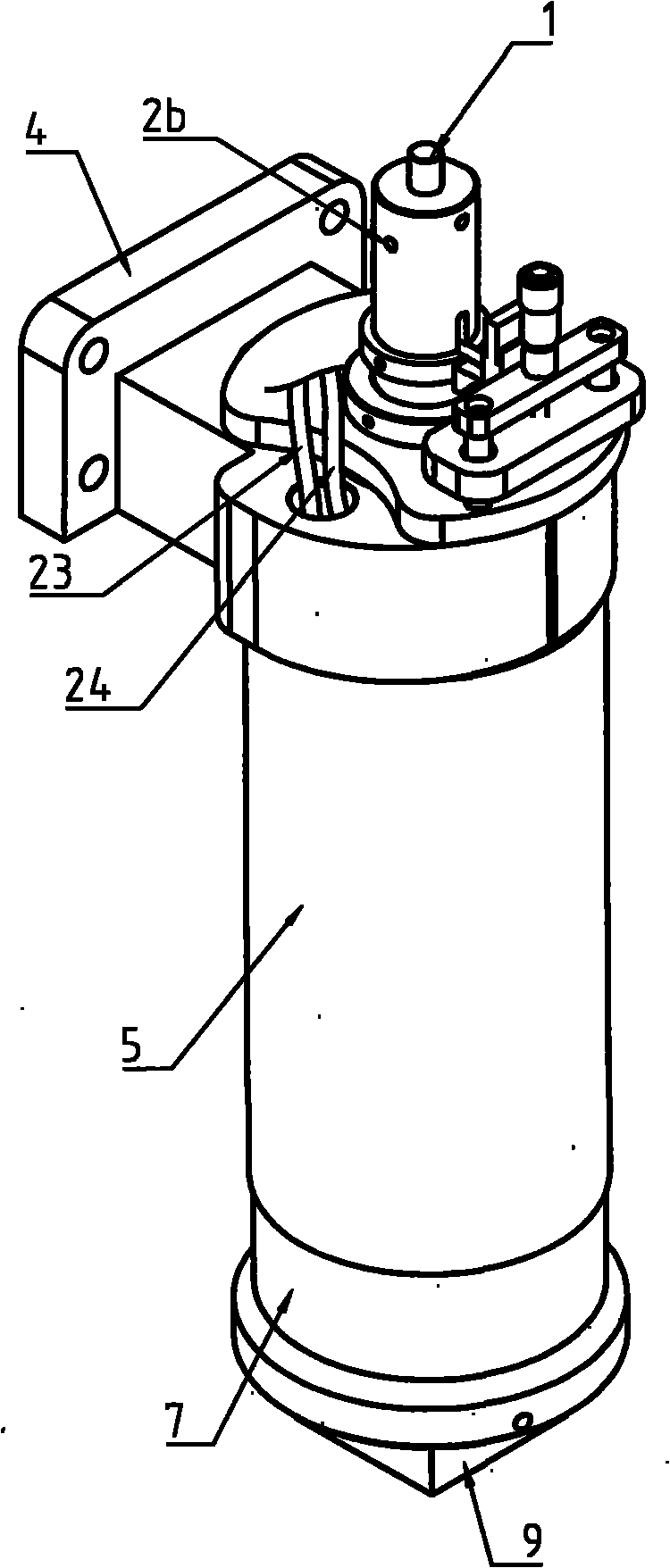

[0029] Such as Figure 3 to Figure 7 As shown, the desoldering integrated hot air head is mainly composed of fixed seat, suction rod, main shaft, wind cover, hot air pipe and cold air pipe and other components. The main shaft is composed of a hollow shaft 2 and a connecting plate 11 fixedly mounted on the bottom of the shaft 2 . The upper part of the spindle shaft 2 is rotatably mounted in the fixed seat 4 through a plurality of ball bearings 3 . The ball bearing 3 has higher precision and less resistance than the sliding bearing. The upper end of the main shaft rod 2 is fixedly equipped with a transmission shaft 1, and the transmission shaft 1 is driven by an external motor.

[0030] Suction bar is made up of suction pipe 12 and suction nozzle 10, and suction nozzle 10 is threadedly connected with suction pipe 12, can take off and replace at will. The suction pipe 12 is installed in the inner hole of the main shaft shaft 2 , and the outer wall of the suction pipe 12 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com