Sludge storing pipe bag for dehydration and dehydration method

A pipe bag and sludge technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of loss of drainage function, easy pollution of the surrounding environment, loss of soil holding function, etc., and achieve significant economic and social ecological benefits. Drainage consolidation time, the effect of overcoming insufficient dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

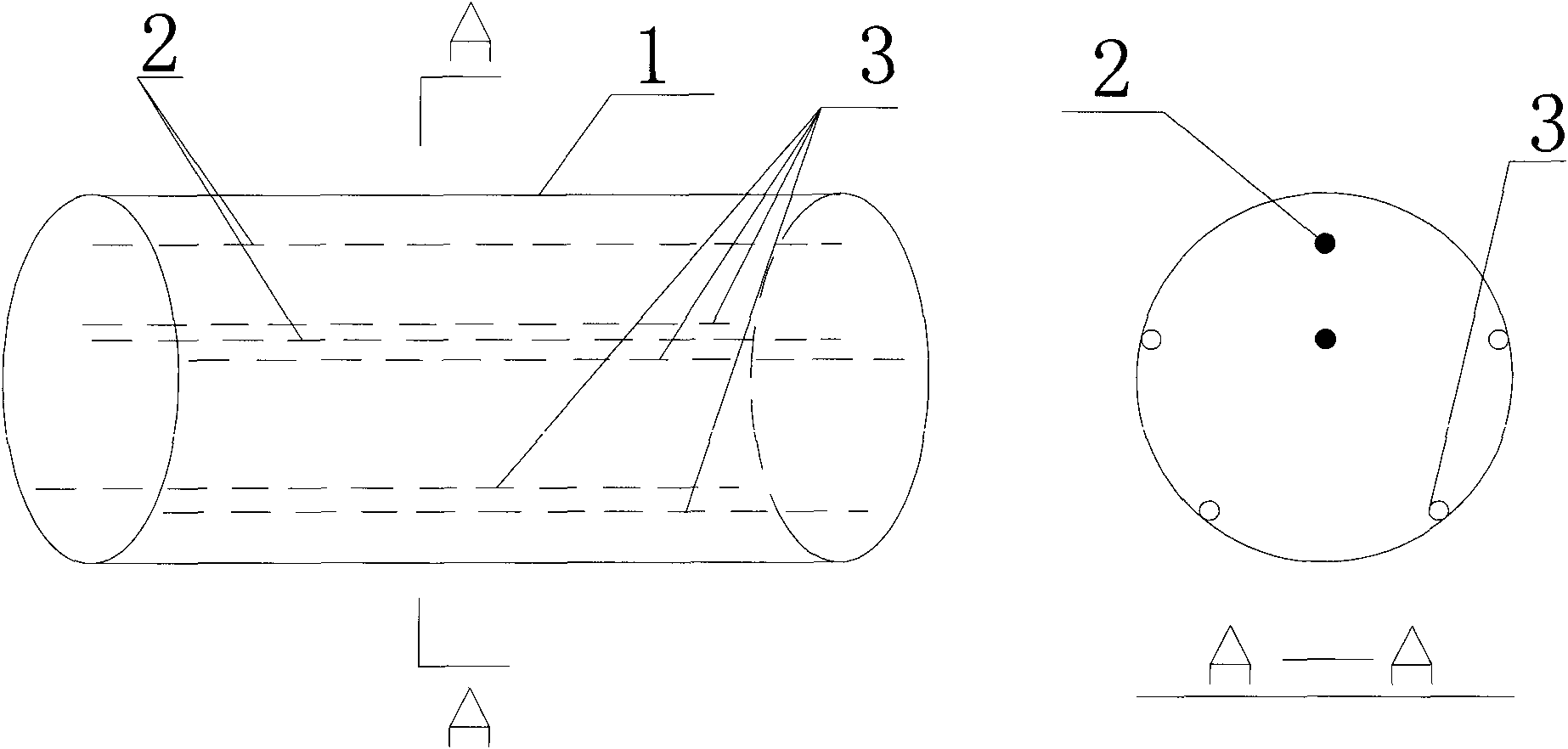

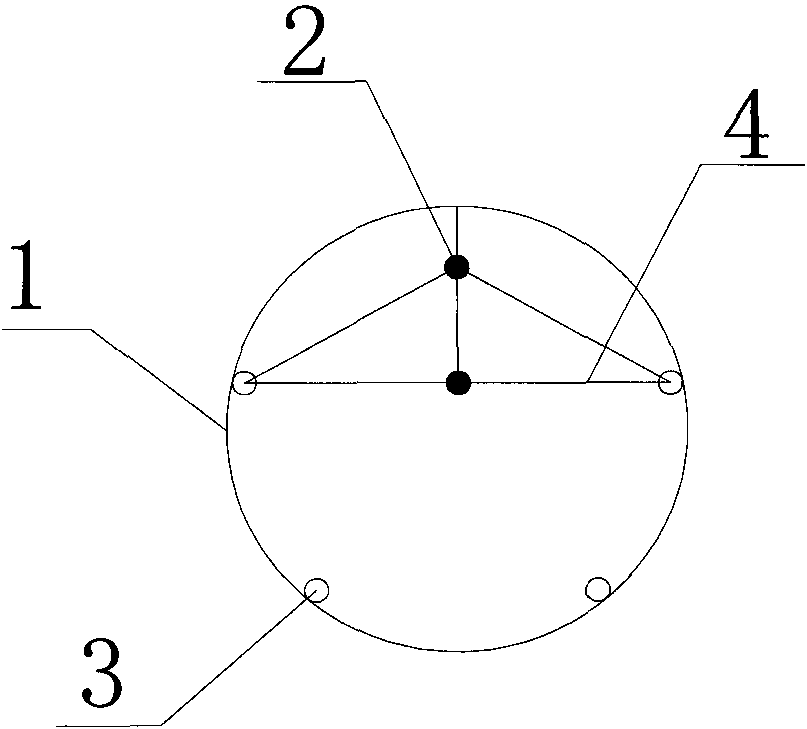

[0024] A silt storage pipe bag for sludge dewatering comprises a pipe bag body 1, and an anode 2 and a cathode 3 connected to a power source are arranged in the pipe bag body 1.

[0025] The anode 2 is a steel bar or a geoelectric material rod (not easy to corrode). There are two anodes in total, which are arranged in the middle and upper part of the pipe bag. One anode is fixed by three binding straps 4, two binding straps are connected from the cathode, and one anode is The root binding tape is sewn on the top to ensure that the anode can be suspended at the predetermined position in the center and upper part of the tube bag after filling.

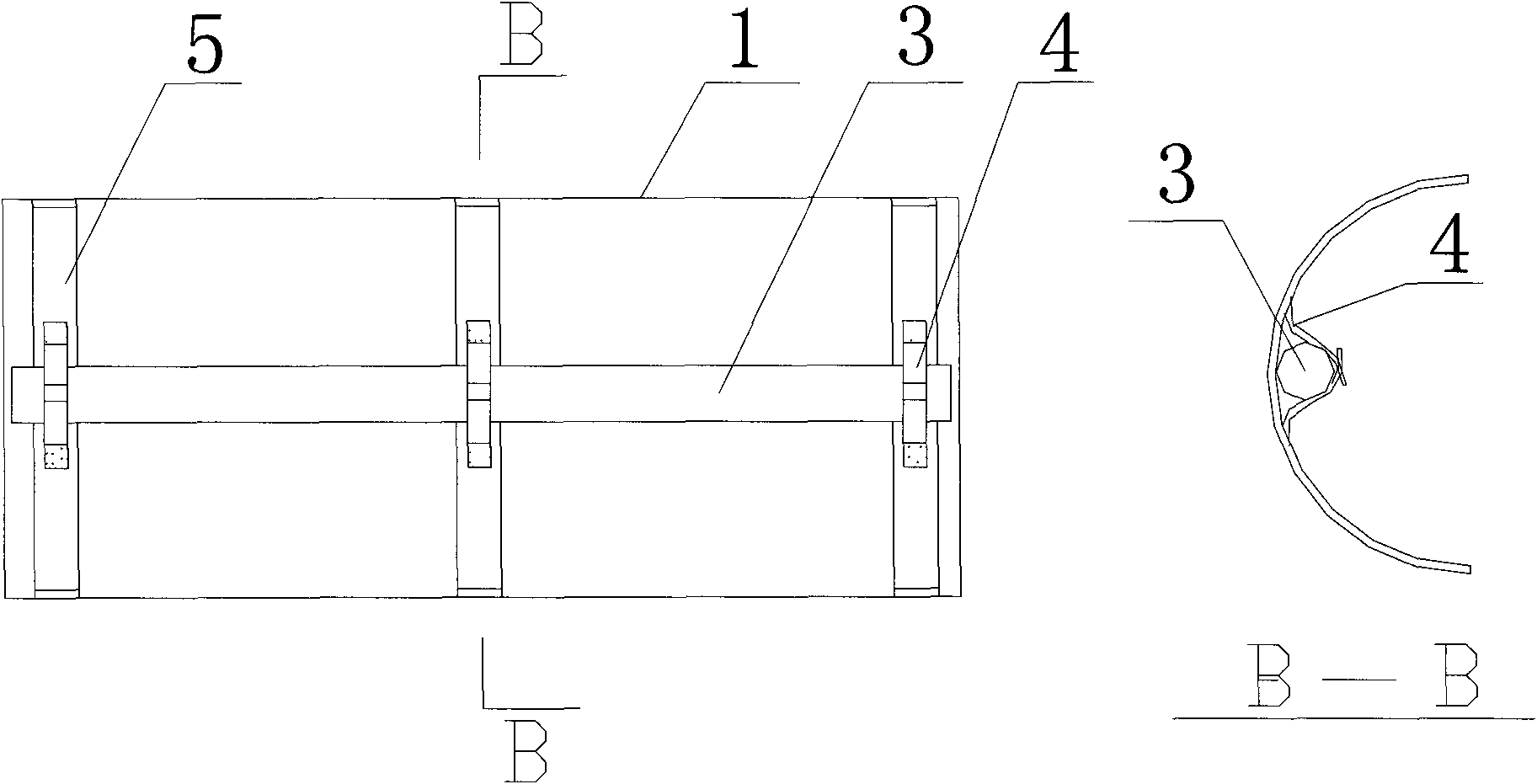

[0026] Cathode 3 is a porous steel tube covered with geotextile for reverse filtration. A total of four cathodes are fixed on both side walls and bottom of the tube bag. The specific method is to compound a circle of reinforcing tape 5 at the position of the inner wall of the tube bag that needs to be fixed to strengthen the tube bag wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com