Process flow of supercritical carbon dioxide dyeing combining with urea production system

A carbon dioxide and production system technology, applied in dyeing, textile material treatment, liquid/gas/steam treatment of a certain length of textile materials, etc., can solve the problems of high operation, maintenance and management costs, small equipment scale, and poor manufacturing technology Mature and other issues, to achieve the effect of reducing one-time equipment investment, improving production efficiency, and reducing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1. According to the process conditions of supercritical carbon dioxide dyeing, through different combinations of system operation carbon dioxide compressors, spare carbon dioxide compressors and newly added carbon dioxide compressors in urea production, the dyeing / cleaning pressure does not exceed the pressure of the urea production system. Implementation of supercritical carbon dioxide dyeing process:

[0033] For example, the total amount of carbon dioxide in a urea production system is 594Nm 3 / min, urea production gas 475Nm 3 / min, excess carbon dioxide is 119Nm 3 / min, the system uses 4M32-125 / 210 carbon dioxide compressor, its exhaust pressure is 21MPa, and the rated carbon dioxide displacement of a single unit is 125Nm 3 / min, four open and two standby, the sum of the excess carbon dioxide displacement of the system running compressors is 25Nm 3 / min.

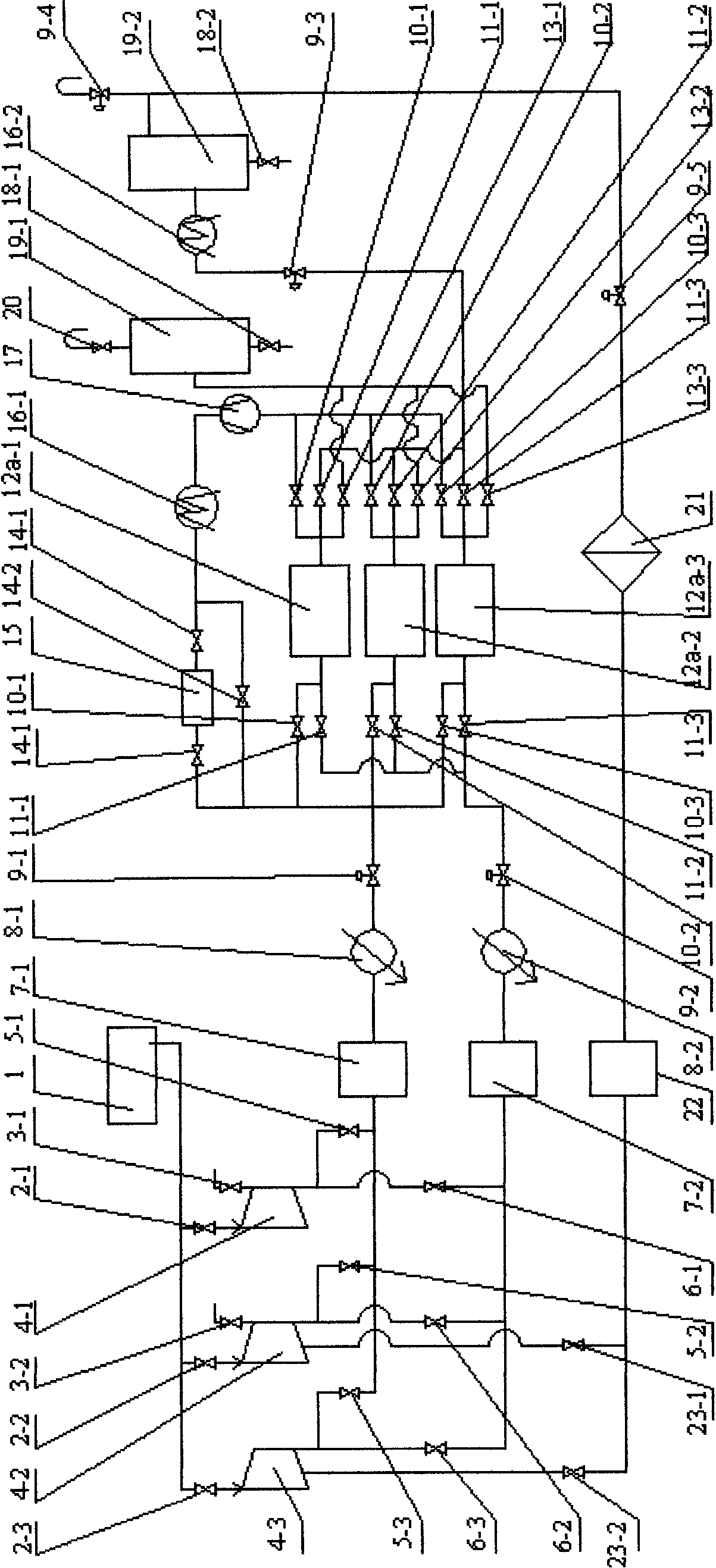

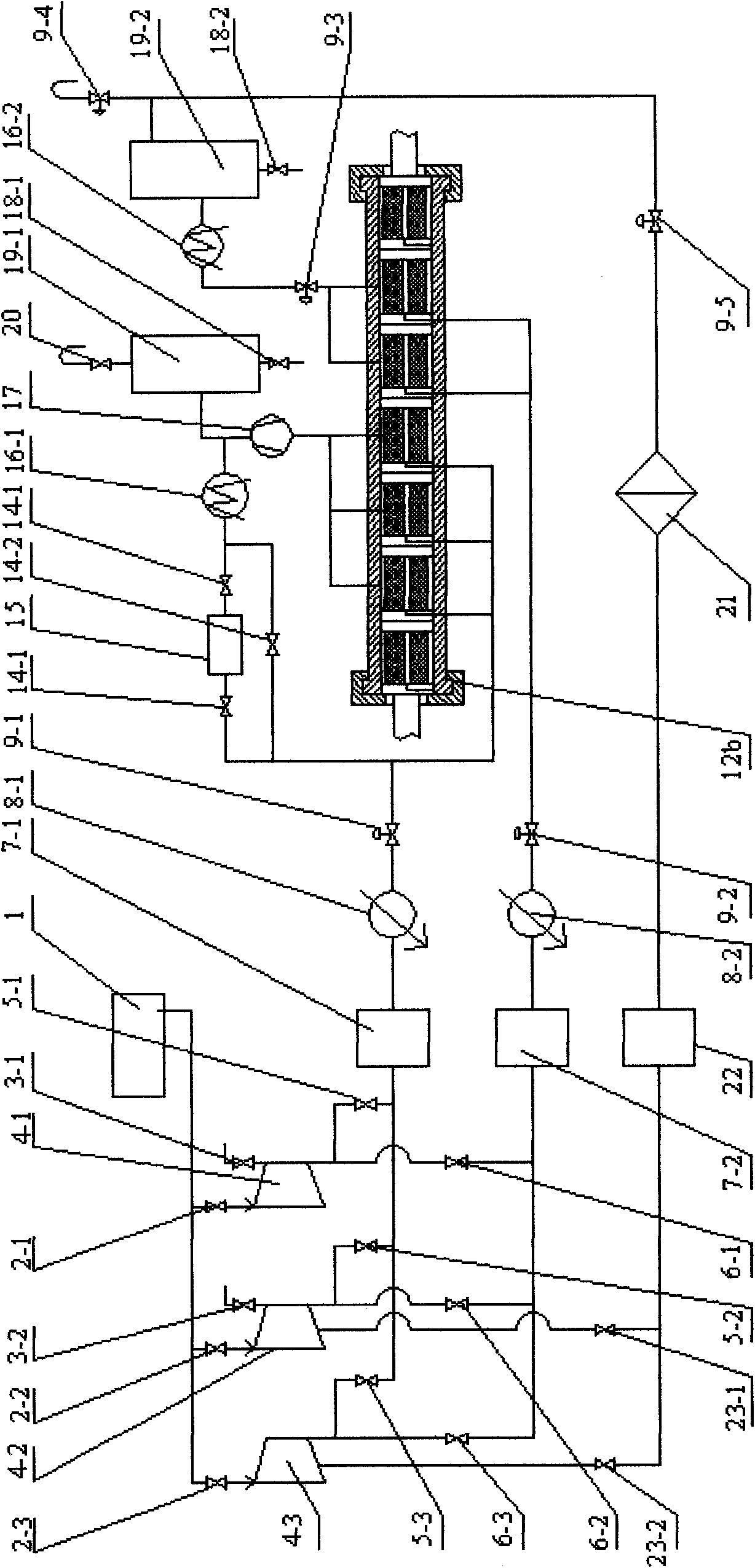

[0034](1) The implementation process of the supercritical carbon dioxide dyeing process formed b...

Embodiment 2

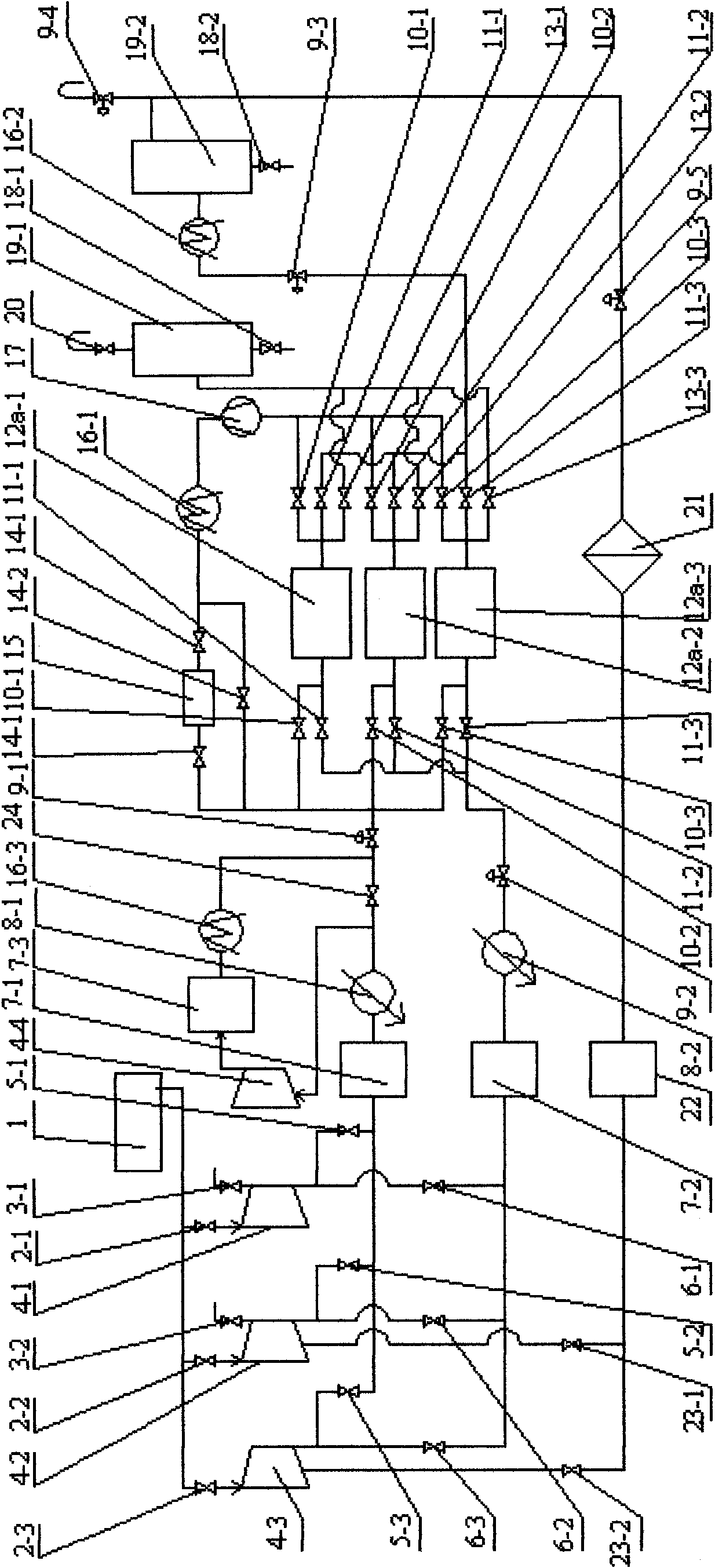

[0055] Embodiment 2: According to the process conditions of supercritical carbon dioxide dyeing, different combinations of operating the carbon dioxide compressor in the urea production system, the system spare carbon dioxide compressor and the newly added carbon dioxide compressor are used, and the carbon dioxide booster compressor is added to form an extraction Implementation of supercritical carbon dioxide extraction process with pressure exceeding urea production system pressure:

[0056] Such as image 3 , Figure 4 As shown, the connection mode of each process unit before the dyeing heater 8-1 and after the dyeing regulating valve 9-1 is exactly the same as the various processes (1) to (7) in Embodiment 1; the difference is that the dyeing heater 8 After -1, it is divided into two roads, and one road directly reaches the dyeing regulating valve 9-1 through the high and low pressure cut-off valve 24 opened between the dyeing heater 8-1 and the dyeing regulating valve 9-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com