System and method for automatically testing I/O pin of CAN bus control module

A CAN bus and control module technology, which is applied in the field of automatic testing of the I/O pins of the CAN bus control module, can solve the problems of low test efficiency, increase the labor level of inspectors, and individual operation errors, so as to improve test efficiency and reduce Human input and economic cost, the effect of high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

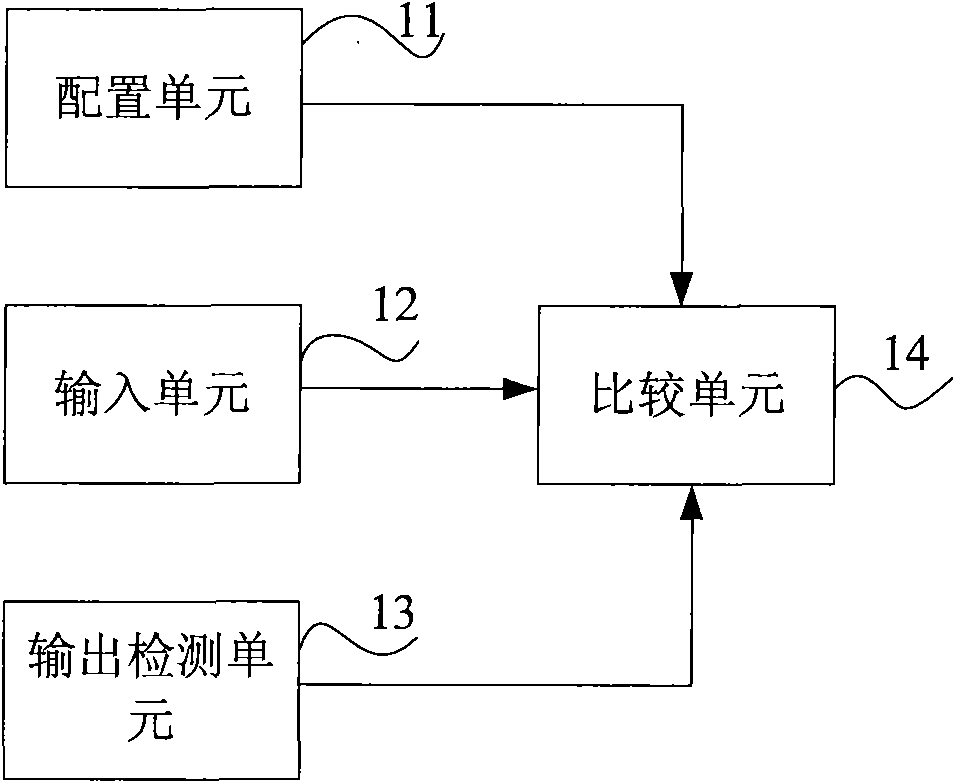

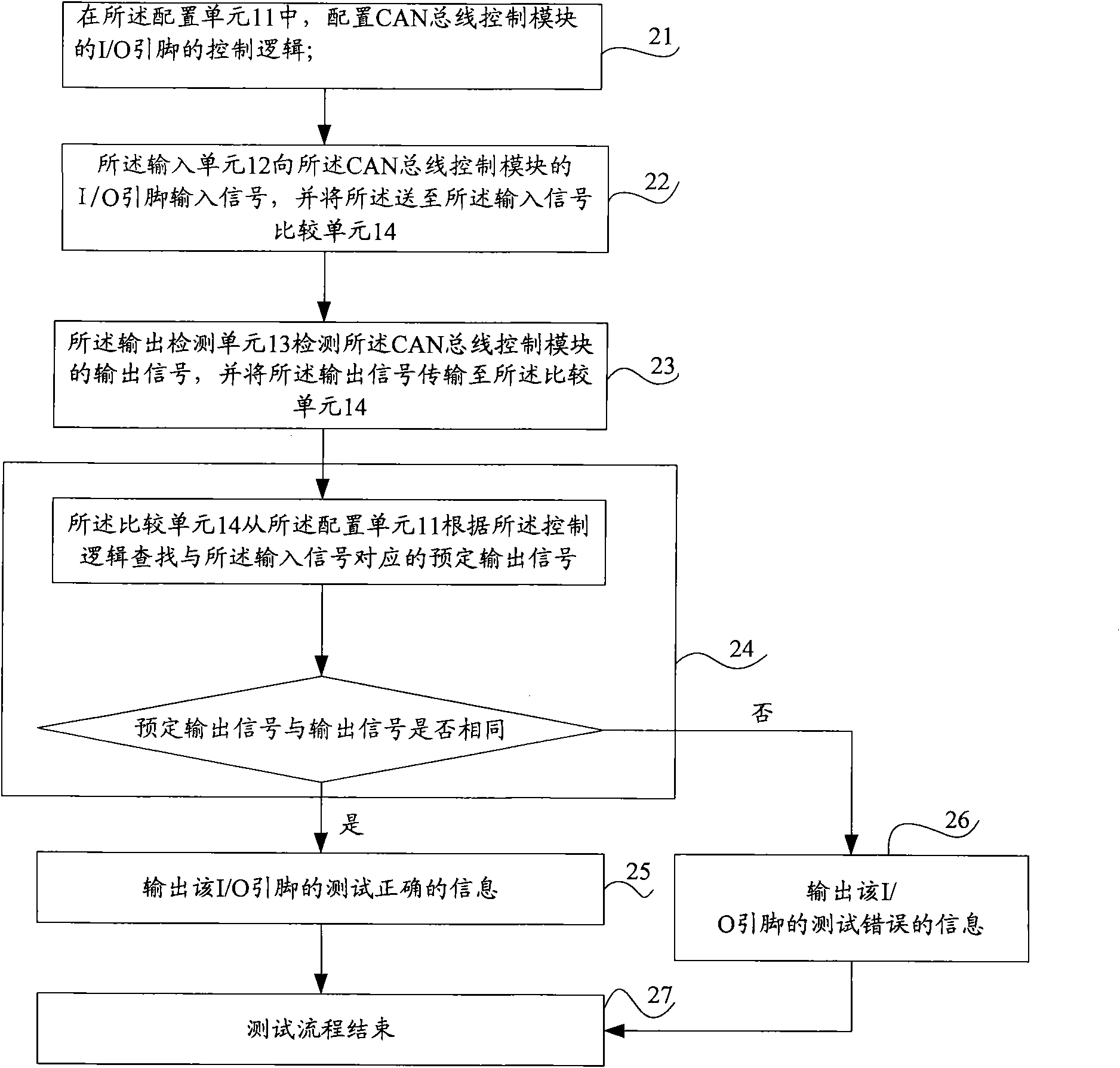

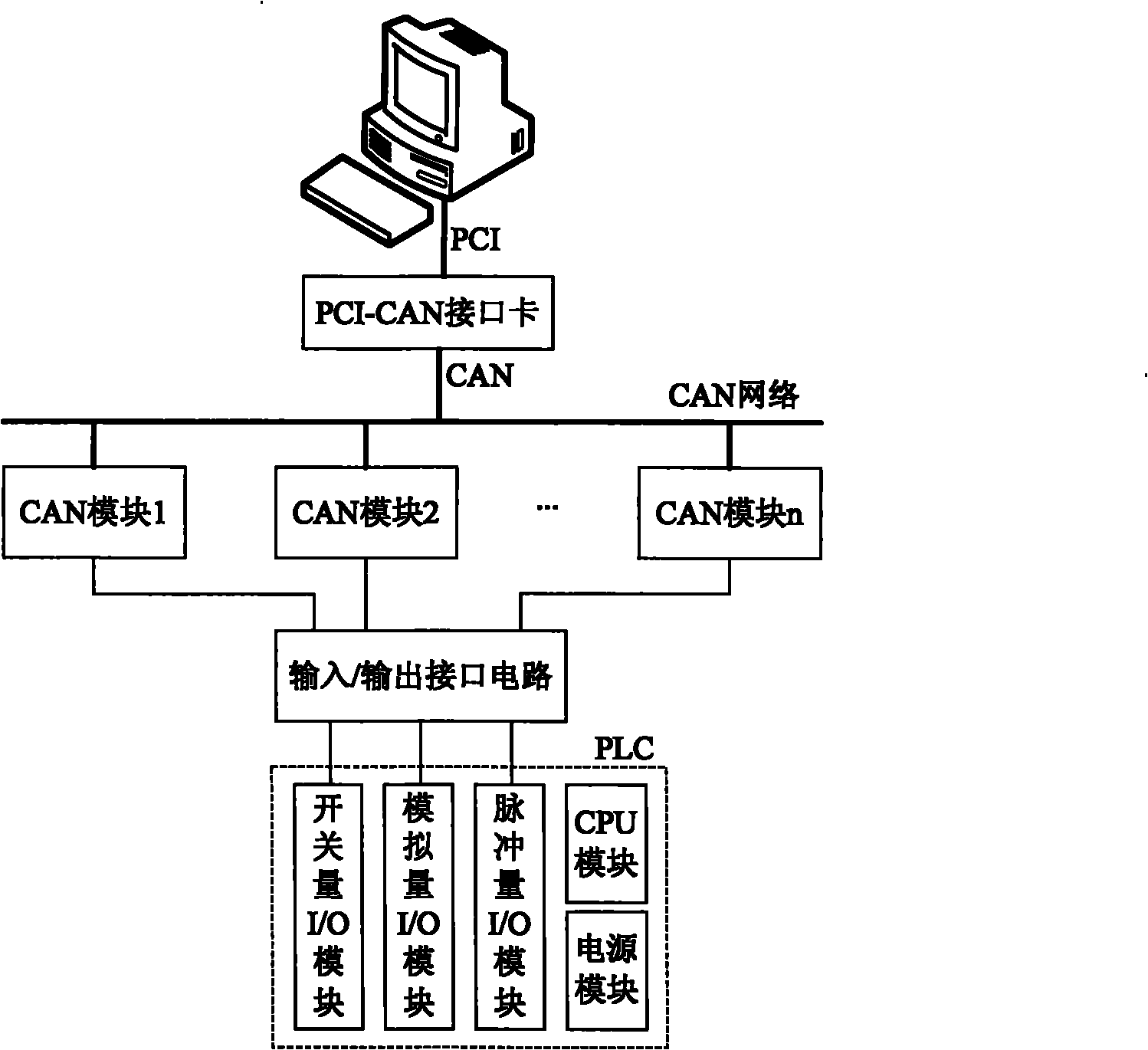

[0046] Such as figure 1 Shown, the system of the I / O pin of automatic test CAN bus control module of the present invention comprises configuration unit 11, input unit 12, output detection unit 13 and comparison unit 14, wherein:

[0047] The configuration unit 11 is used to configure the control logic of the I / O pin of the CAN bus control module;

[0048] The input unit 12 is configured to input signals to the I / O pins of the CAN bus control module, and transmit the input signals to the comparison unit 14;

[0049] The output detection unit 13 is used to detect the output signal of the CAN bus control module, and transmit the output signal to the comparison unit 14;

[0050] The comparison unit 14 is configured to find a predetermined output signal corresponding to the input signal from the configuration unit 11 according to the control logic, and compare the predetermined output signal with the output signal, and if the two are the same, then Output the information that the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com