Method and apparatus for applying material to a surface of an anode of an x-ray source, anode and x-ray source

An X-ray and X-ray tube technology, which is used in the fields of anode surfaces and devices for applying materials to X-ray sources, anodes and X-ray sources, to reduce the number of light sources and avoid contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

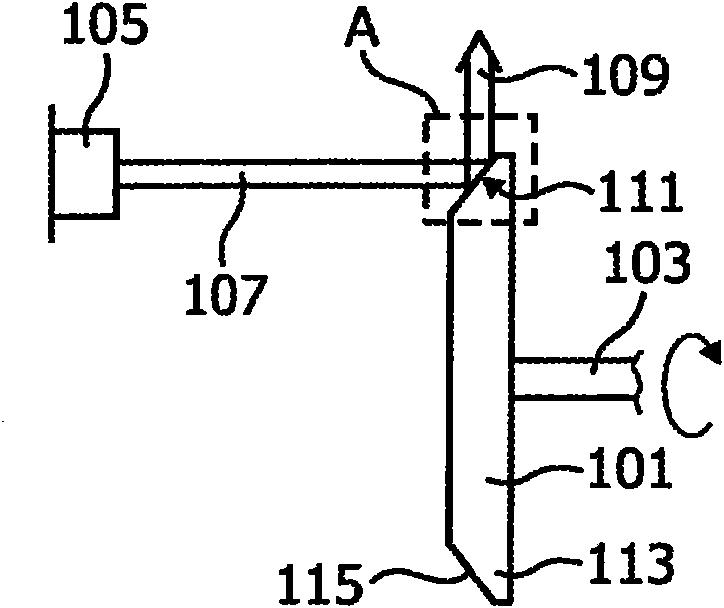

[0063] figure 1 An X-ray tube arrangement comprising a disc anode 101 and an electron source 105 is shown. Anode 101 is disk-shaped and includes a heavy metal such as tungsten, rhenium or molybdenum. At its circumferential edge 113 , the anode 101 comprises an inclined surface serving as an X-ray emitting surface 115 for emitting an X-ray beam 109 when irradiated by an electron beam 107 from an electron source 105 . At the focal locus 111 where the electron beam 107 strikes the X-ray emitting surface 115, cracks or pits may occur after continued operation of the X-ray tube.

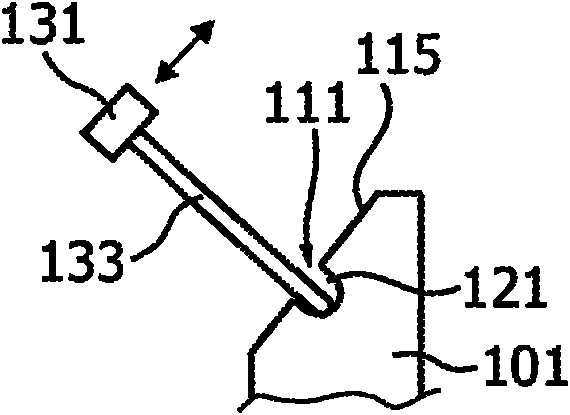

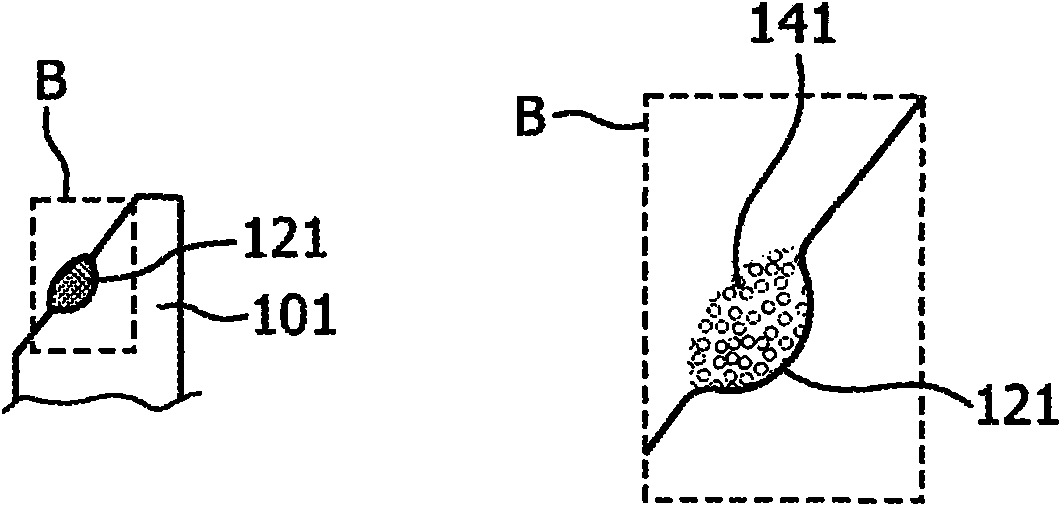

[0064] Figures 2a to 2d shows that in the different processing steps of an embodiment of the method according to the invention figure 1 The area A around the focus locus 111 indicated in .

[0065] Such as Figure 2a As shown, a pit 121 formed on the focal track 111 can be detected and its depth can be measured using a laser beam 133 from a first laser 131 . as Figure 2a Indicated by the arrow, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com