Steel lattice plate automatic edge wrapping machine

A steel grating and hemming machine technology, which is applied in resistance welding equipment, welding equipment, metal processing equipment, etc., to achieve the effects of improving the precision and quality of hemming, improving the working environment, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

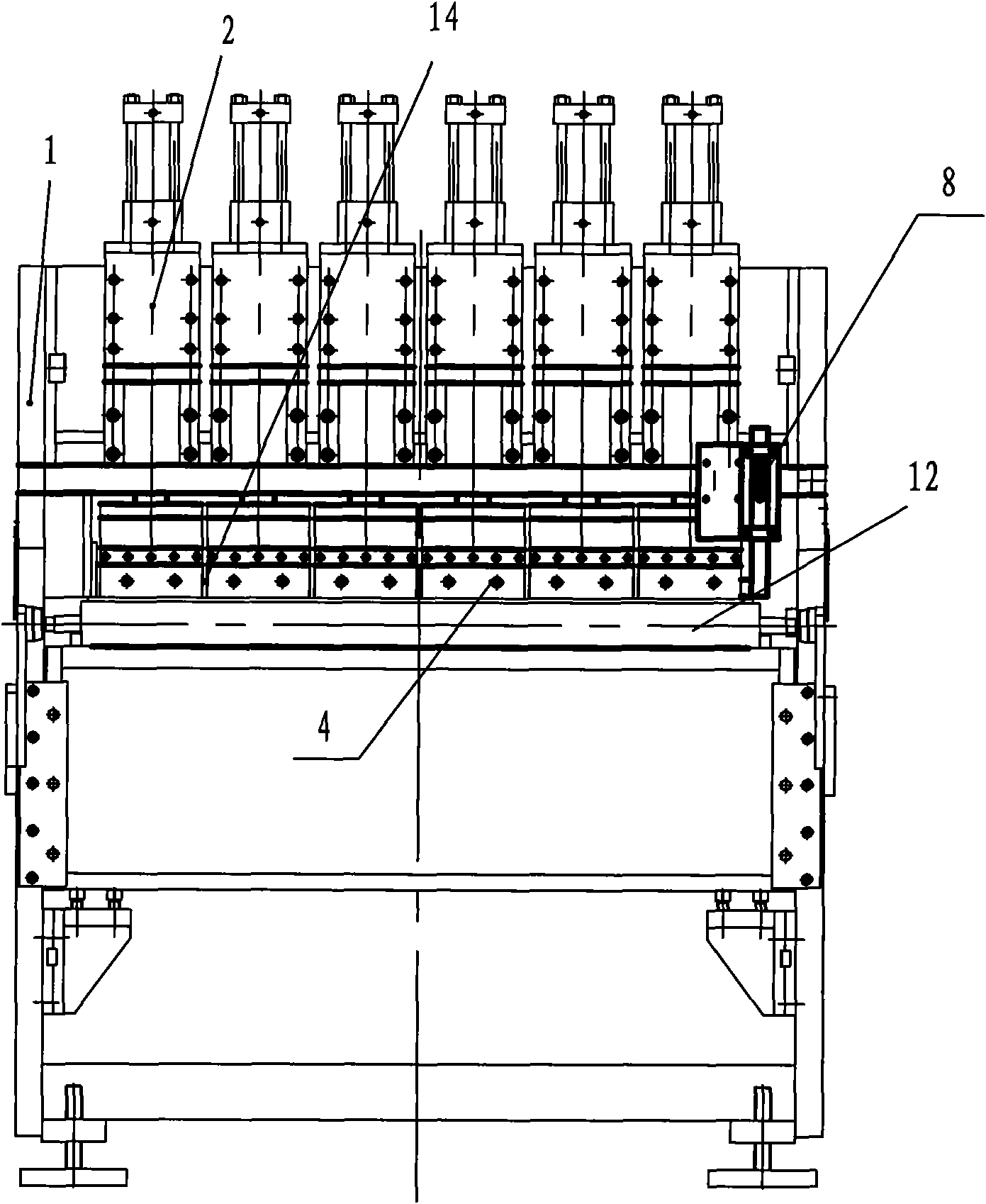

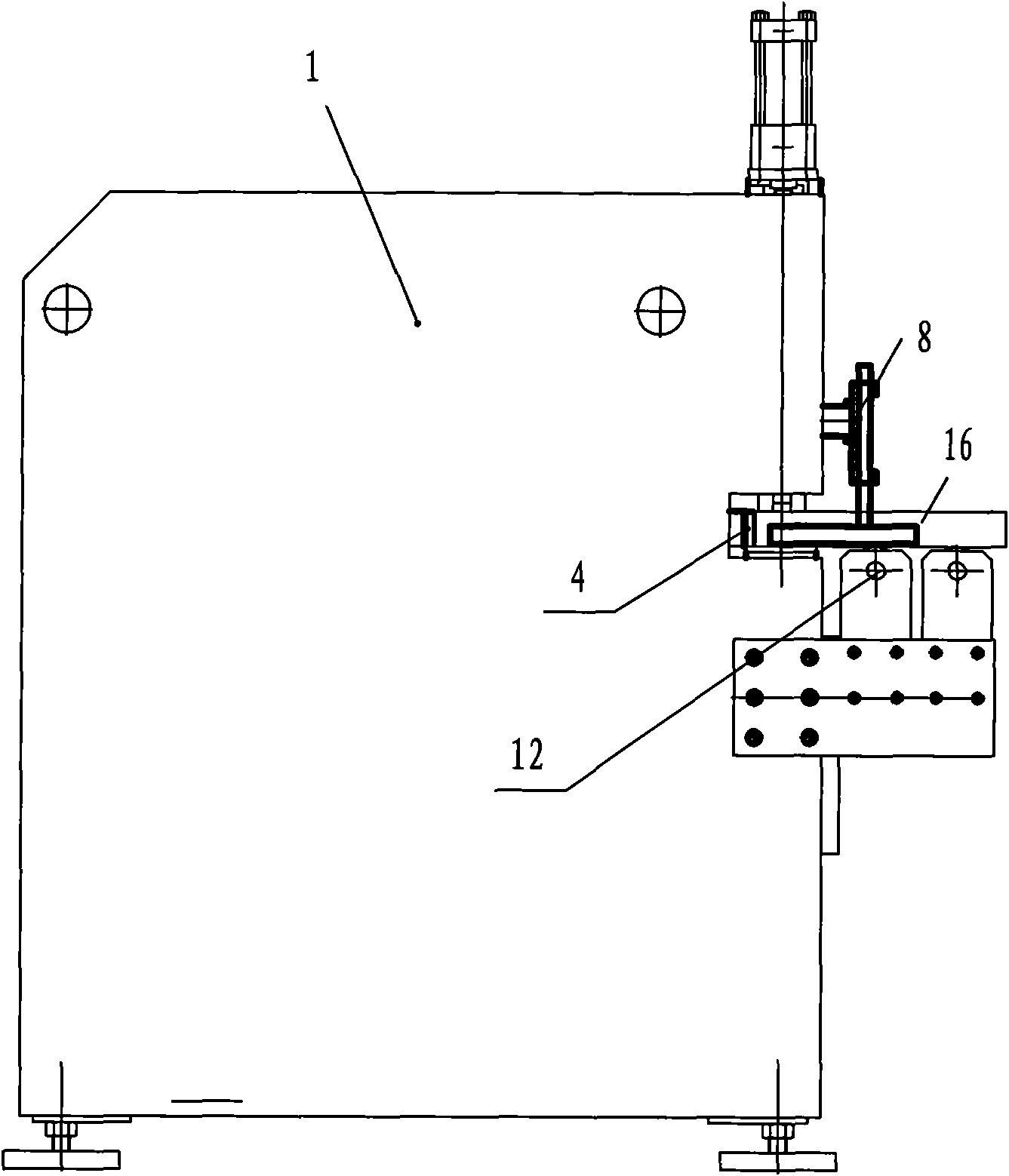

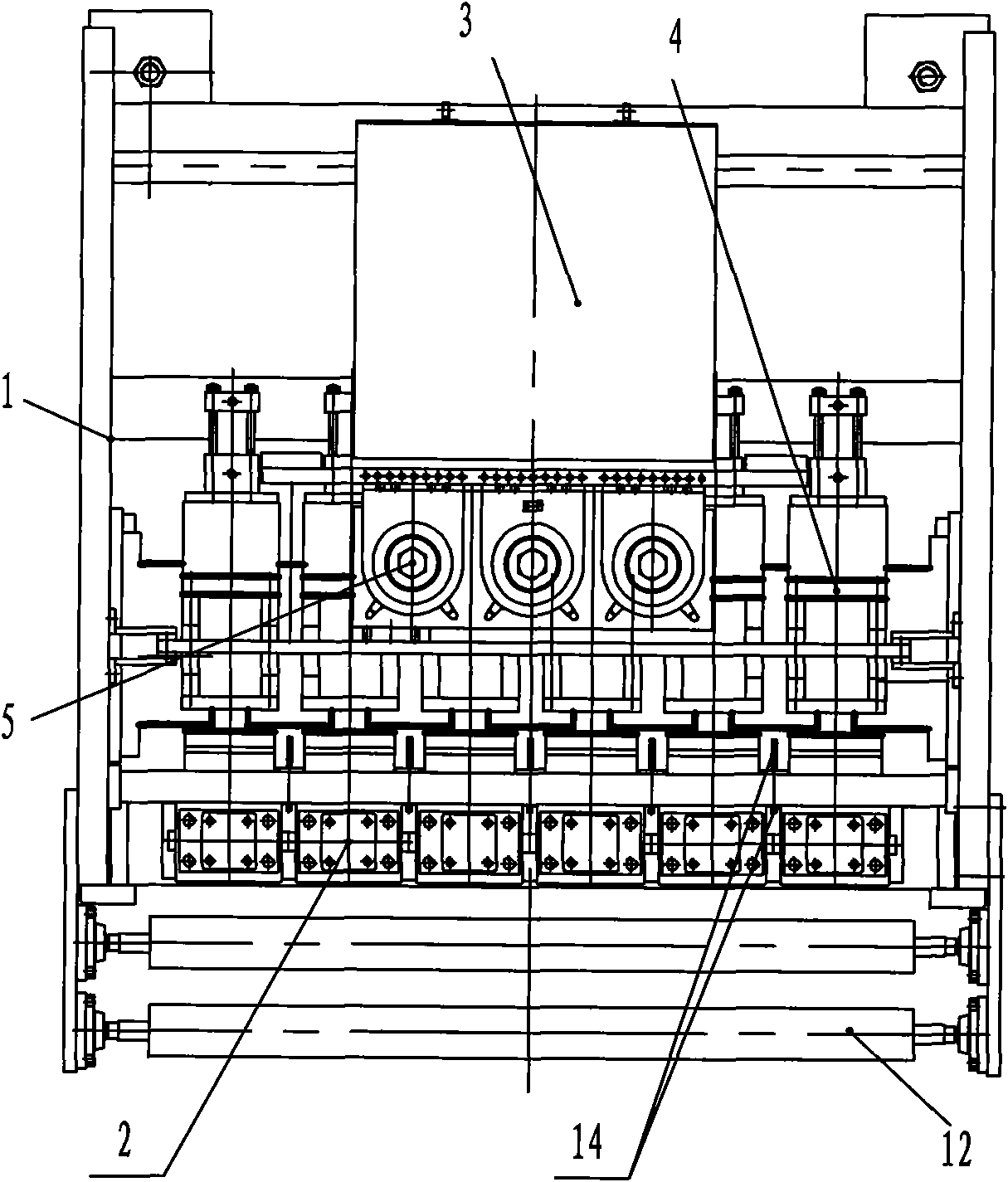

[0016] 1. Machine base, 2. Upper clamping cylinder, 3. Transformer, 4. Pressure welding cylinder, 5. Rectifier tube, 6. Connecting soft copper bar, 7. First insulating pad, 8. Positioning mechanism, 9. Negative connection Copper bar, 10. Second insulating pad, 11. Lower electrode seat, 12. Auxiliary roller, 13. Hydraulic station, 14. Positioning block, 15. Flat steel to be hemmed, 16. Steel grating to be hemmed.

[0017] The lower electrode base 11 is set on the machine base 1, and the upper clamping cylinder 2 is set on the upper part of the machine base 1 corresponding to the lower electrode base 11, and the end of the piston rod of the upper clamping cylinder 2 is provided for clamping The clamping head of the side steel grating 16; the transformer 3 is arranged on the upper part of the machine base 1 and the side of the upper clamping cylinder 2, and the rectifier tube 5 is connected to the transformer 3; the current output terminal of the lower electrode holder 11 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap