Ball screw jacking type automatic anti-flee wheel shelf

A ball screw, roller frame technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding quality, unable to improve work efficiency, etc., to achieve convenient operation, good safety protection function, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

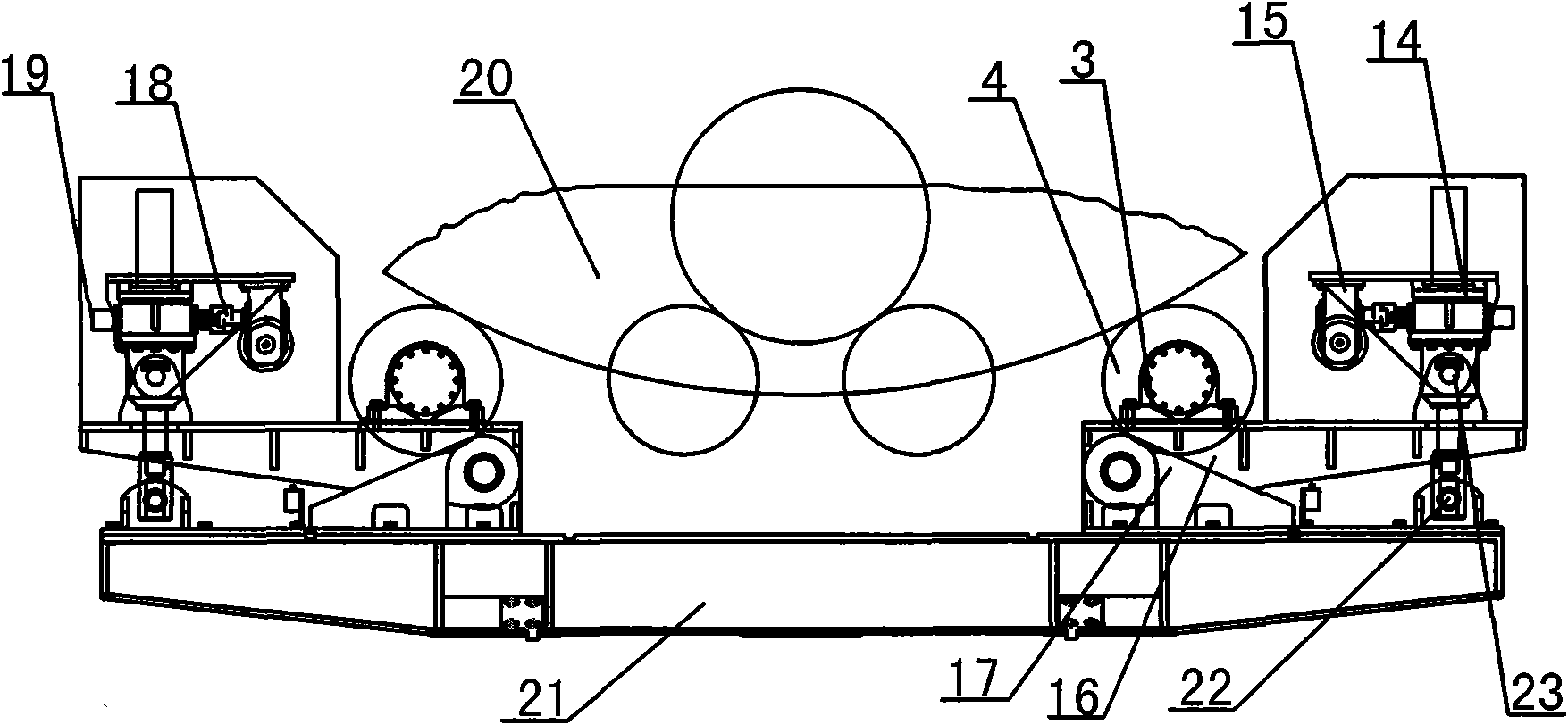

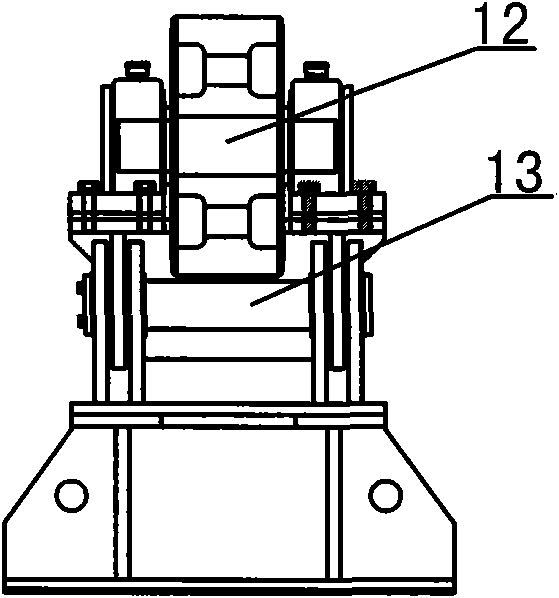

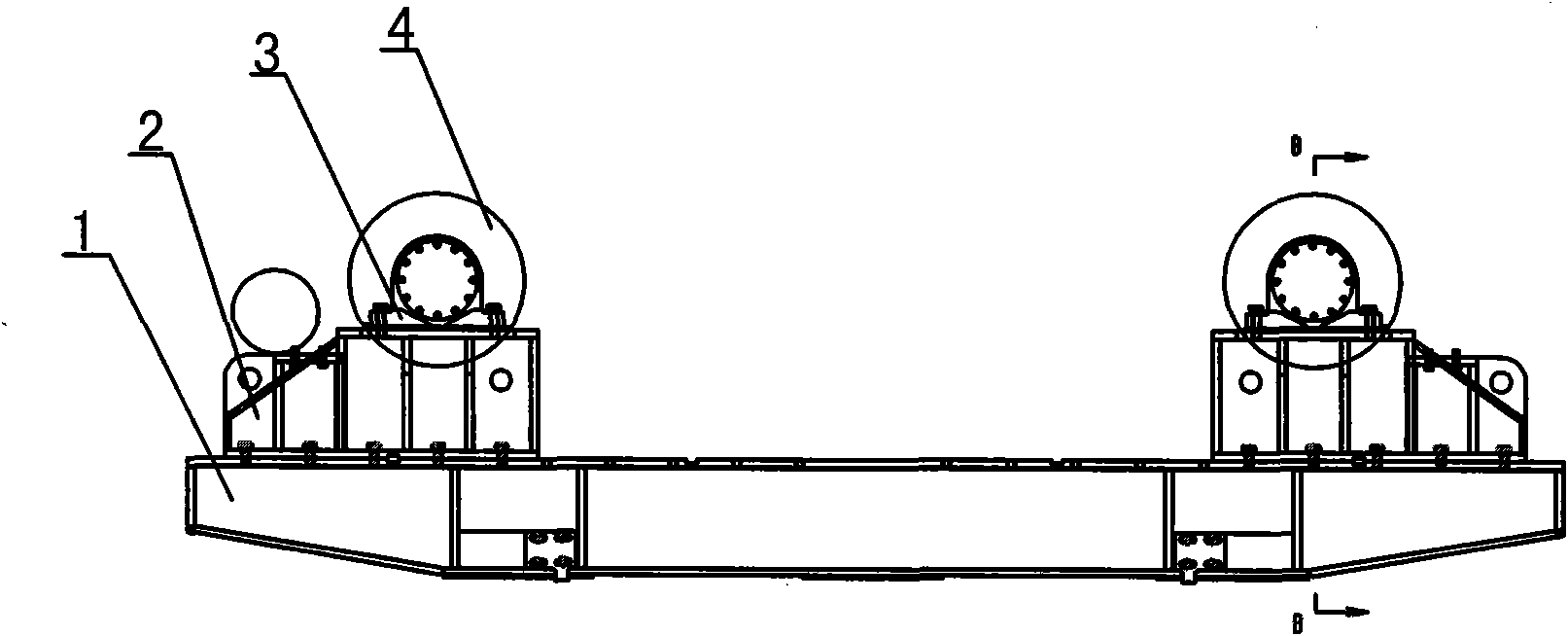

[0015] Such as Figure 1-5 As shown, the ball screw jacking type automatic anti-channeling roller frame according to the present invention includes four parts: the driving roller frame, the driven roller frame, the detection device and the electric control component. The active roller frame is provided with an active base 1 , the two sides of the active base 1 are connected by bolts to two active roller seats 2, the upper part of the active roller seat 2 is bolted to the bearing seat 3, the middle part of the driving shaft 6 is installed with a roller 4, and the other end is connected to the drive reducer 7, and the drive reducer 7 The flange assembly is connected with the rotary main motor 5; the fixed seat 17 is installed on both sides of the upper part of the driven base 21 of the driven roller frame through bolts, the movable seat 16 is connected with the fixed seat 17 through the pin shaft 13, and the front of the upper part of the movable seat 16 The bearing seat 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com