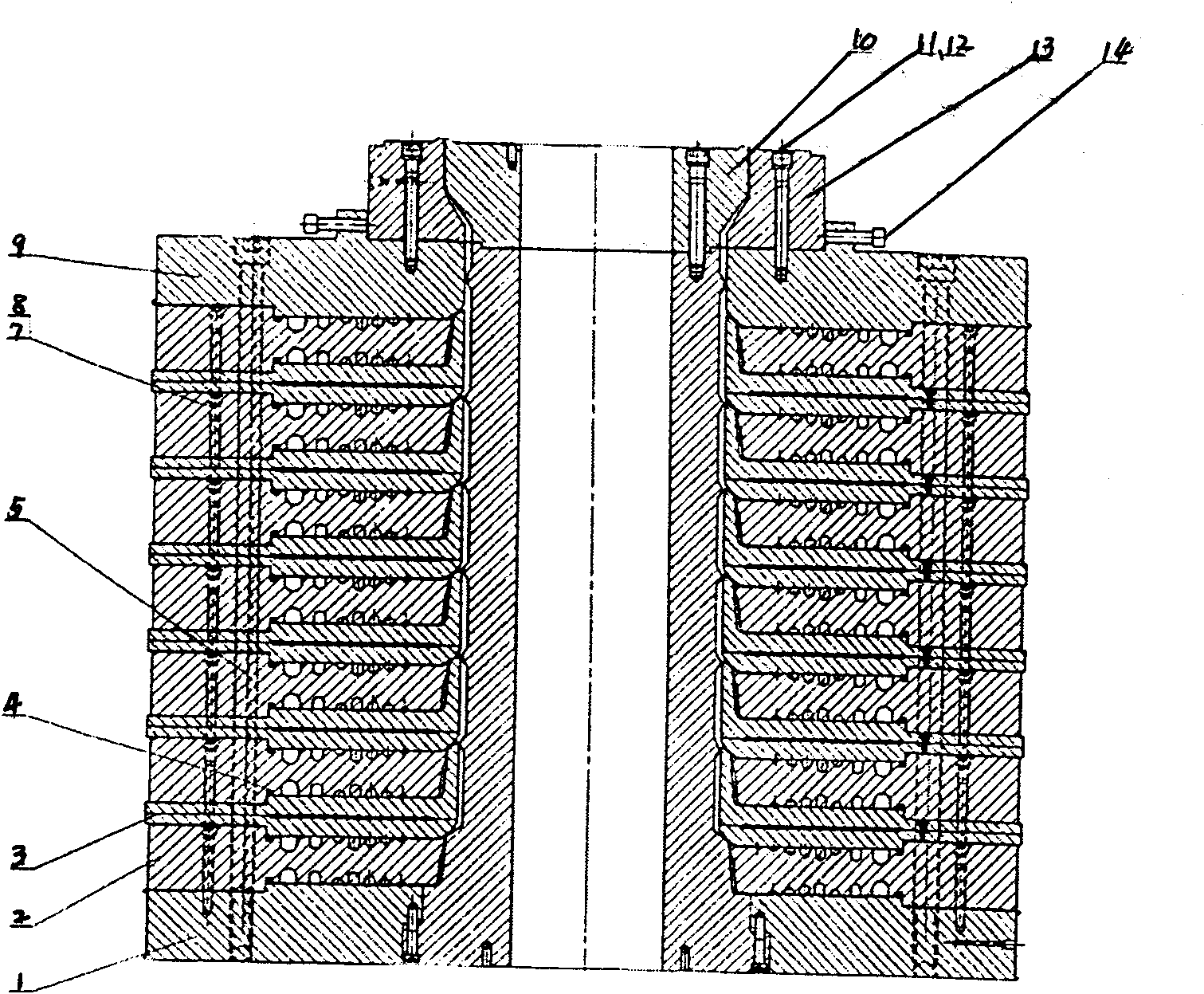

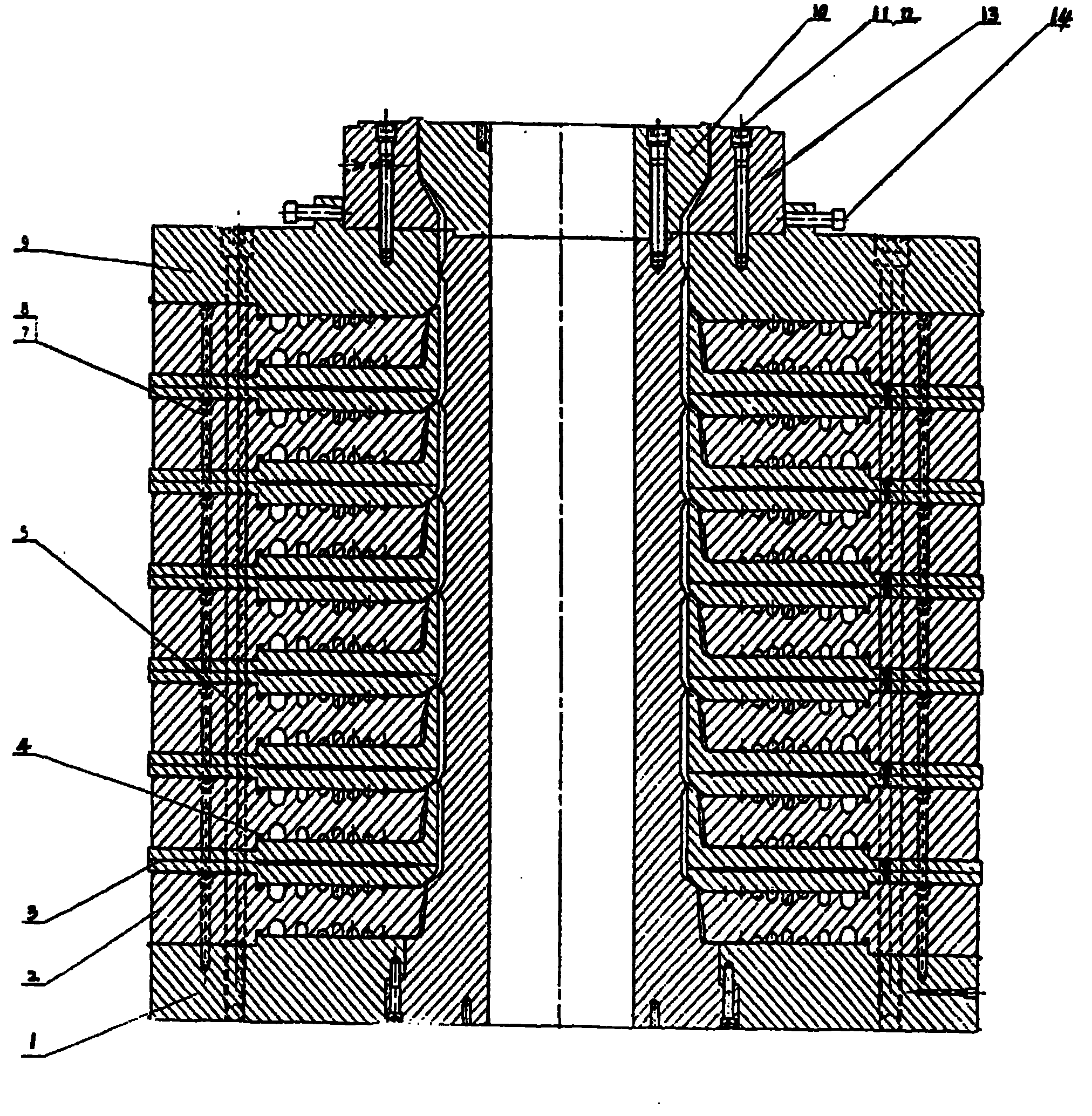

Machine head of seven-layer coextrusion high barrier film blow molding machine

A high-barrier film and blow molding machine technology, which is applied in the field of extrusion blow molding machine head, can solve the problems of low tensile strength and elongation at break, low compression density of the head, and poor discharge uniformity. Achieve the effect of high tensile strength and elongation at break, high compression density of the machine head, and good uniformity of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

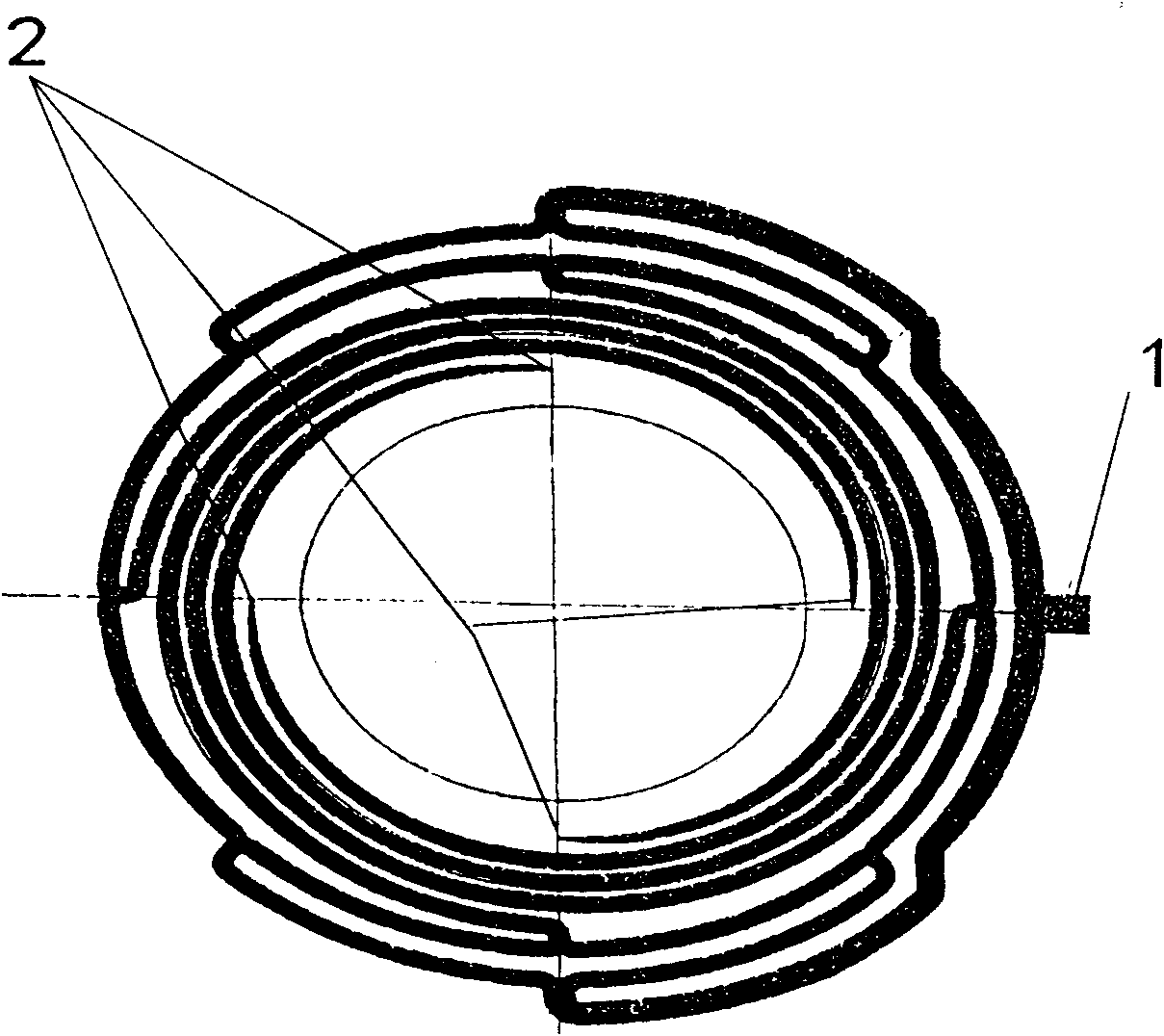

[0019] Utilize the working process of the present invention: the thermoplastic material is pulverized by the extruder through the hopper, heated to a molten state, enters the machine head of the present invention, passes through a feed port of each layer (totally seven layers), and passes through the double-helix plane superposition machine. Inside the head, runner plate 2 of 2 n It is extruded in the form of a seven-layer composite fluid, and the thickness of the product is adjusted through the inner die 10 and the outer die 13 placed on the upper end of the machine head, and is cooled by the air ring to form a film.

[0020] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com