Single-shaft heating steam turbine unit capable of running as steam-extraction turbine unit, back-pressure turbine unit and pure condensing turbine unit

A heat supply steam turbine unit, steam turbine technology, applied in the direction of steam engine device, mechanical equipment, steam application, etc., can solve the problems of increasing atmospheric heat pollution, inoperability of back pressure machine, poor economic benefits, etc., to achieve convenient and fast operation mode, operation The effect of flexibility and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

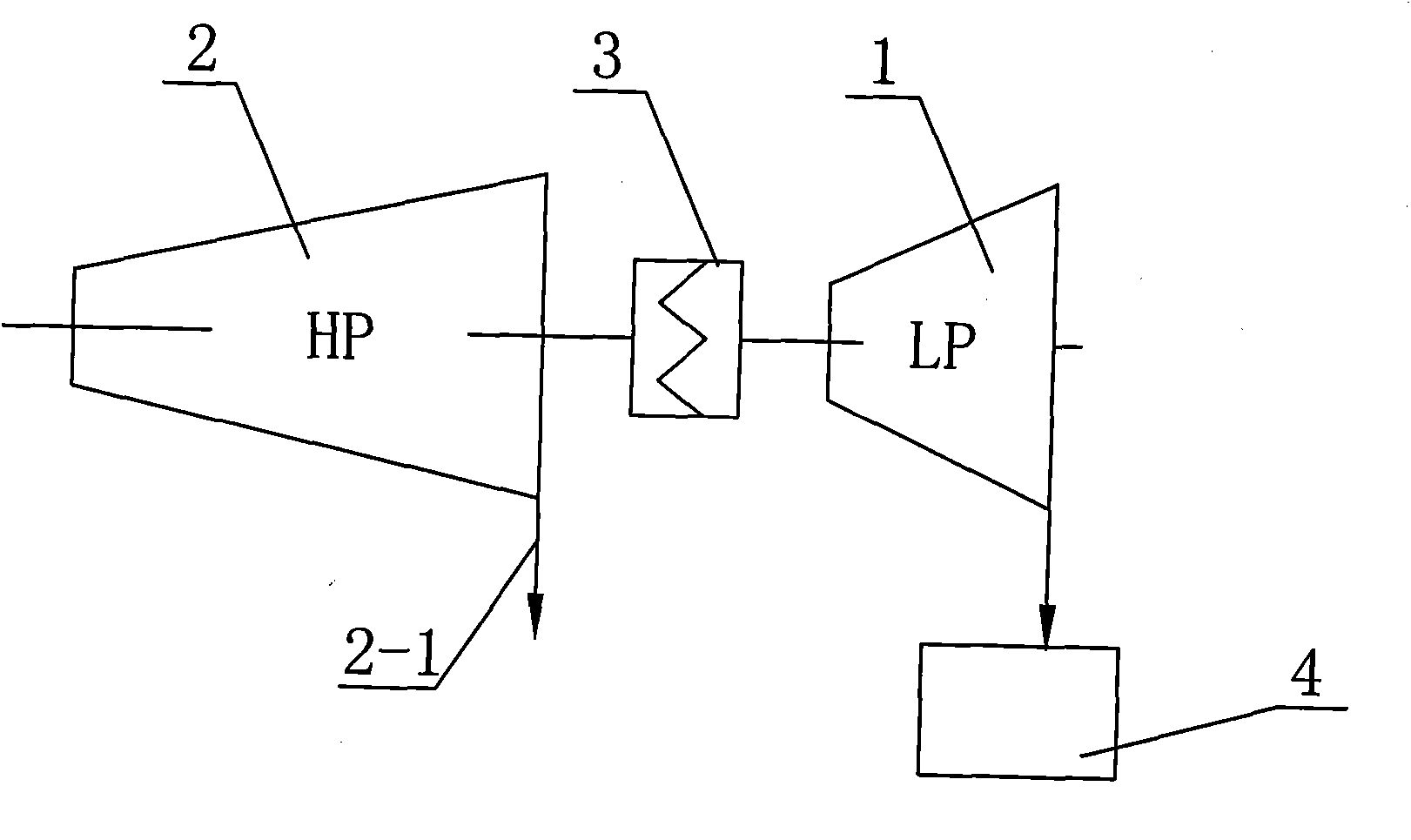

[0009] Specific implementation mode one: as figure 1 As shown, the single-shaft heating turbine unit described in this embodiment that can operate as extraction, back pressure, and pure condensation includes an extraction condensing turbine and a condenser 4, and the heating turbine unit also includes an SSS clutch 3; The extraction condensing steam turbine has a high-pressure cylinder 2 and an independent low-pressure cylinder 1, the high-pressure cylinder 2 and the independent low-pressure cylinder 1 are coaxial, the high-pressure cylinder 2 and the independent low-pressure cylinder 1 are connected by an SSS clutch 3, and the independent low-pressure cylinder 1 Connected with the condenser 4, the exhaust end of the high-pressure cylinder 2 is provided with a heating and steam extraction port 2-1 of the high-pressure cylinder.

[0010] The extraction and condensing steam turbine described in this embodiment may also be equipped with multiple independent low-pressure cylinders...

specific Embodiment approach 2

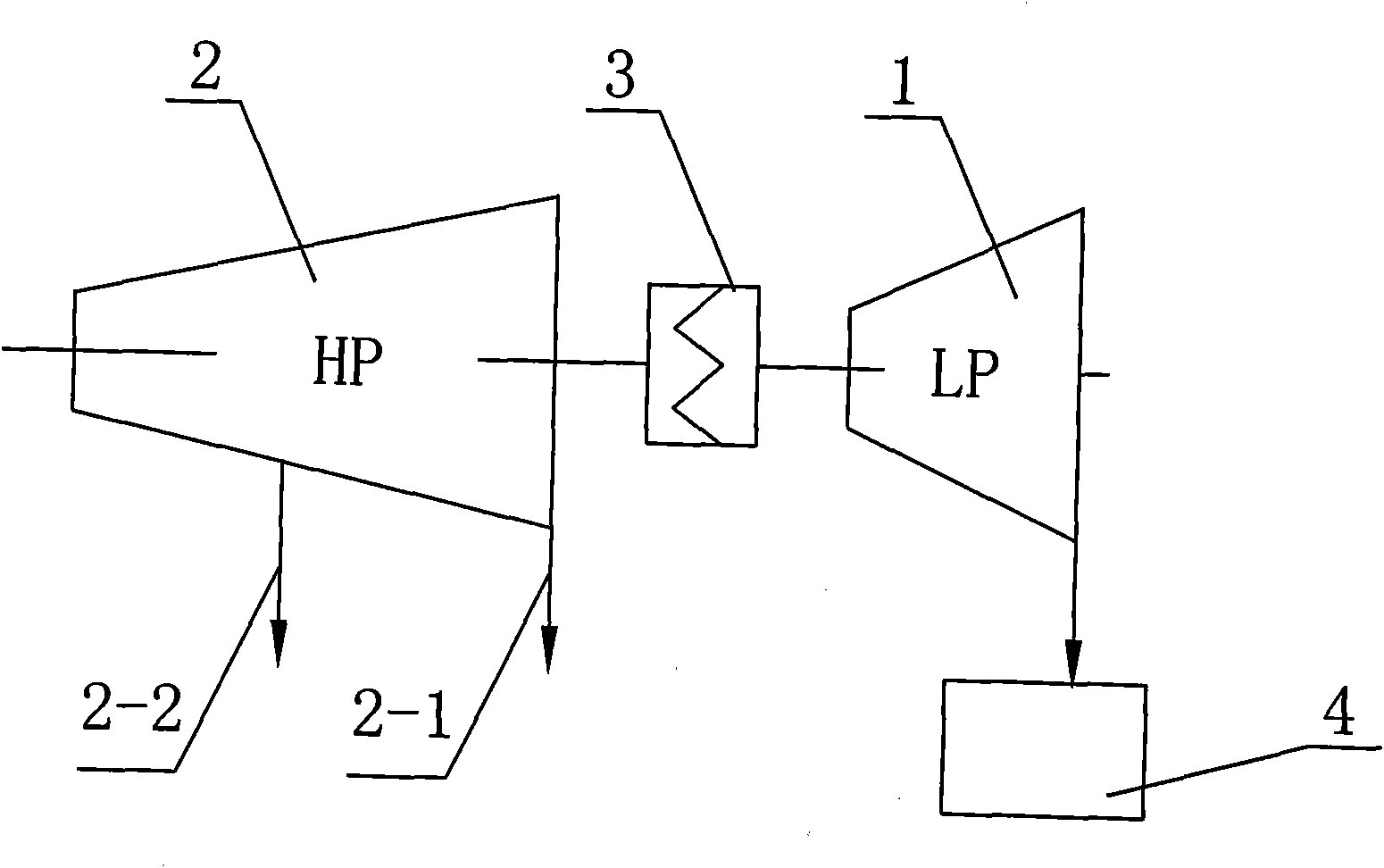

[0011] Specific implementation mode two: as figure 2 As shown, in this embodiment, the industrial steam extraction port 2-2 of the high-pressure cylinder is provided in the middle of the high-pressure cylinder 2 . When in use, the industrial steam extraction port 2-2 of the high-pressure cylinder is connected to the heat network. This embodiment enables the unit to operate not only as double-extraction condensing steam, but also as extraction back-pressure operation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

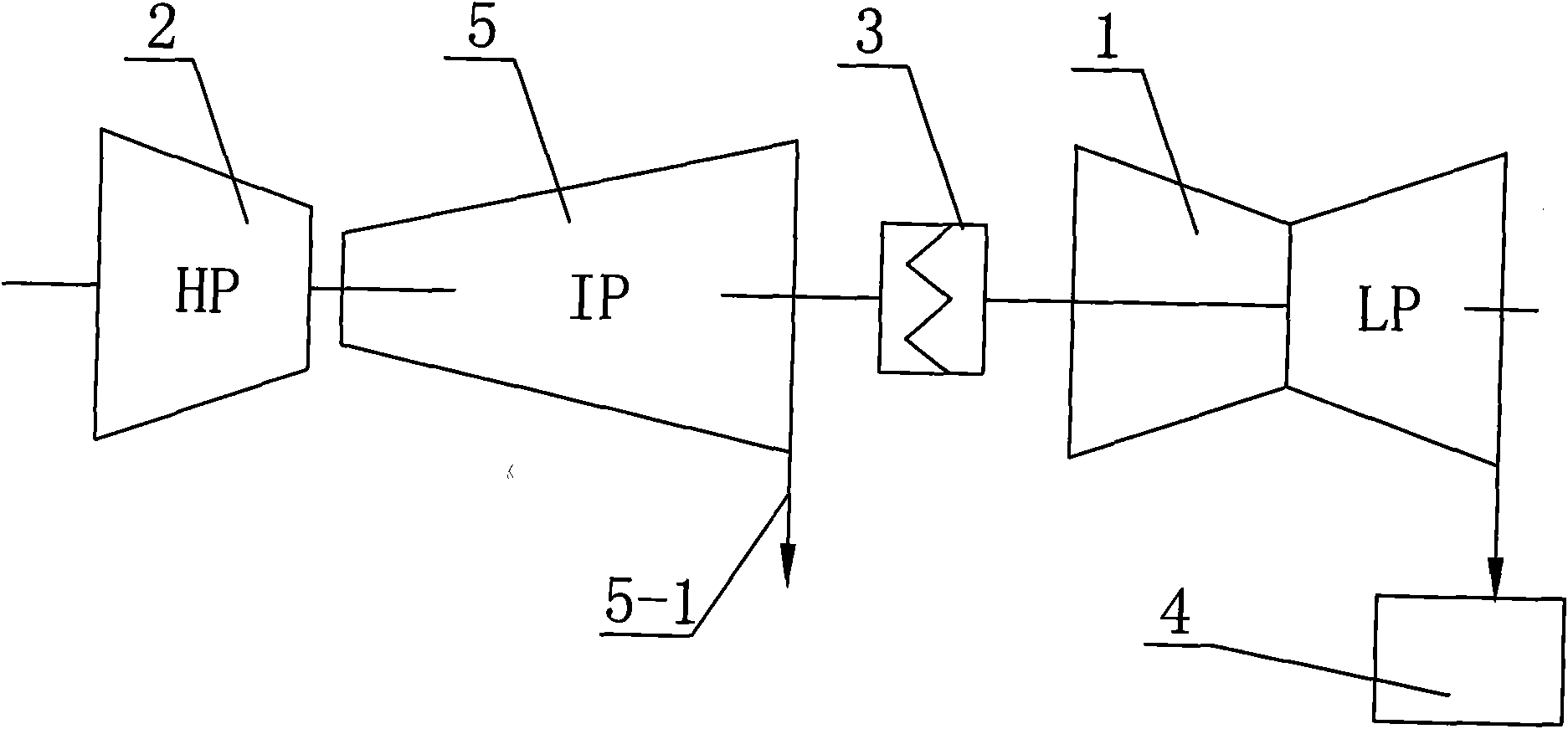

[0012] Specific implementation mode three: as image 3 As shown, the single-shaft heating turbine unit described in this embodiment that can operate as extraction, back pressure, and pure condensation includes an extraction condensing turbine and a condenser 4, and the heating turbine unit also includes an SSS clutch 3; The extraction condensing steam turbine is equipped with an independent low-pressure cylinder 1, a high-pressure cylinder 2 and an intermediate-pressure cylinder 5, the independent low-pressure cylinder 1, high-pressure cylinder 2, and intermediate-pressure cylinder 5 are coaxial, and the intermediate-pressure cylinder 5 is located in the independent low-pressure cylinder. Between cylinder 1 and high pressure cylinder 2, medium pressure cylinder 5 and independent low pressure cylinder 1 are connected by SSS clutch 3, independent low pressure cylinder 1 is connected with condenser 4, and the exhaust end of medium pressure cylinder 5 is equipped with medium pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com