LED backlighting structure provided with converted light source and using free-form surface reflector

A technology of curved surface reflection and backlight structure, applied in the field of backlight systems, can solve the problems of limited thickness reduction and increased number of backlight systems, and achieve the effects of small thickness, large light source angle, and high overall light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

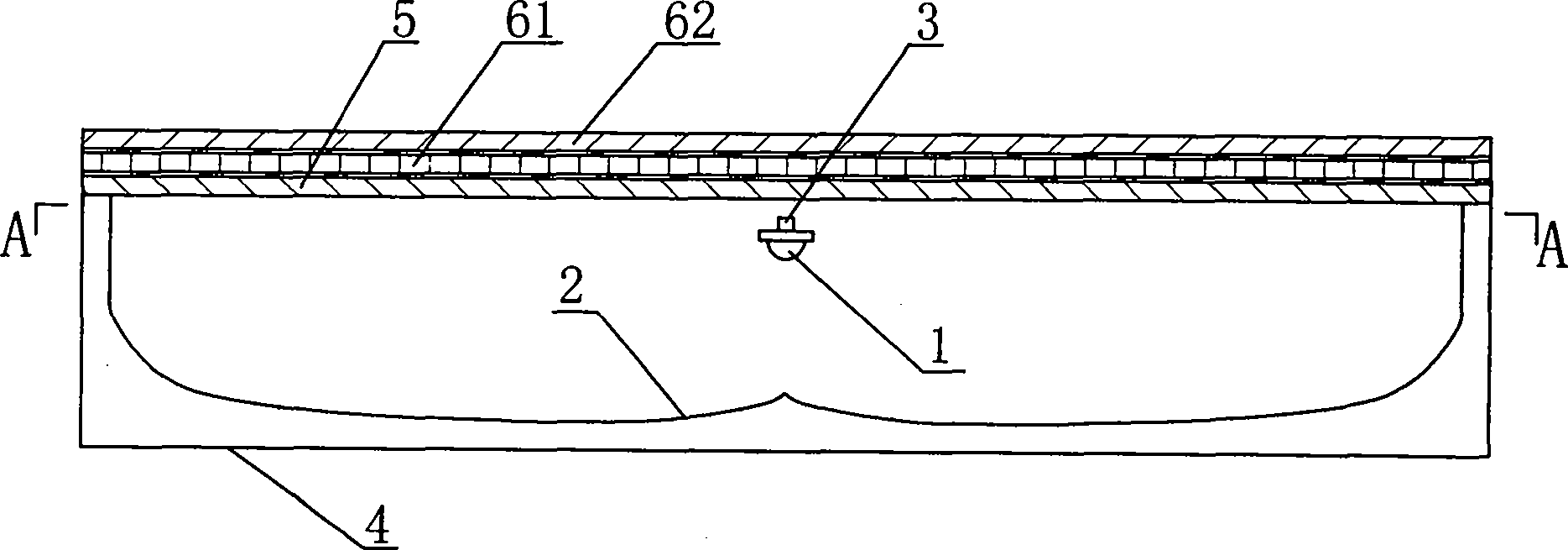

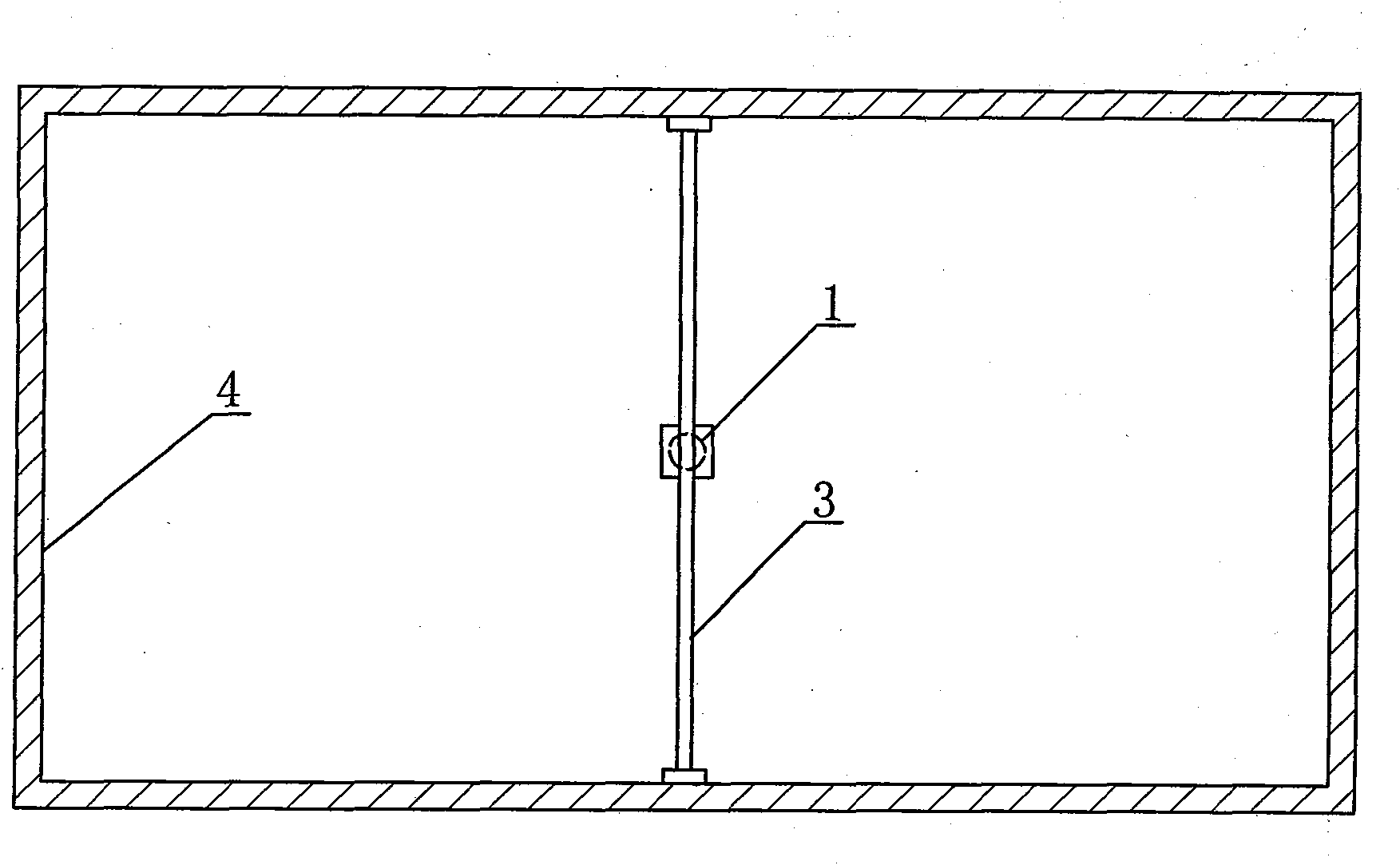

[0031] Such as figure 1 and figure 2 As shown, an LED backlight structure with an inverted light source and a free-form reflector includes a backlight cavity 4 and an LED light source 1. The bottom of the backlight cavity 4 is a free-form reflective surface 2, and the backlight cavity 4 is reflected from the inner wall and the bottom. The free-form reflective surface 2 and the diffusion film 5 placed on the top together form a closed cavity, and the first brightness enhancement film 61, the second brightness enhancement film 62 and the LCD panel are arranged on the diffusion film 5; The LED light source 1 is fixed in the backlight cavity 4 through the light source support frame 3, and is located below the diffuser film 5, the first brightness enhancement film 61, the second brightness enhancement film 62 and the LCD panel and the axis of the free-form reflective surface 2 at the bottom of the backlight cavity 4 above, and the light emitting direction is away from the LCD pan...

Embodiment 2

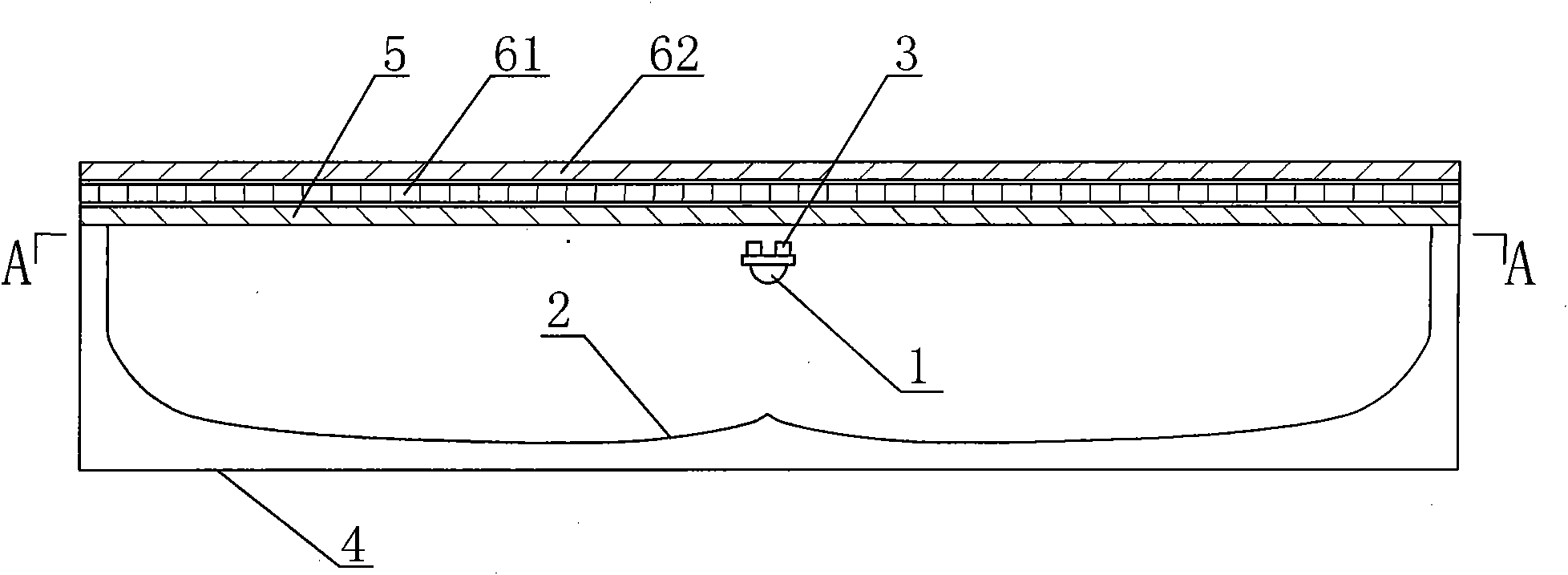

[0036] Such as image 3 , Figure 4 As shown, an LED backlight structure with an inverted light source and a free-form reflector, including a backlight cavity 4, an LED light source 1, a light source support frame 3, a diffusion film 5, a first brightness enhancement film 61 and a second brightness enhancement film 62, The overall structure is similar to that of Embodiment 1, the main difference is that: the light source supporting frame 3 in this embodiment is two metal strips, which are fixedly connected to the backlight cavity 4 .

Embodiment 3

[0038] Such as Figure 5 , Image 6 As shown, an LED backlight structure with an inverted light source and a free-form reflector, including a backlight cavity 4, an LED light source 1, a light source support frame 3, a diffusion film 5, a first brightness enhancement film 61 and a second brightness enhancement film 62, Overall structure is similar to embodiment 1, the main difference is:

[0039] The LED light source 1 of this embodiment is a group of linearly arranged backlight units, each backlight unit is a white LED, and each white LED is respectively fixed on the light source support frame 3, and the light source support frame 3 is two metal bars.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com