Mobile electric furnace coal injection method using bituminous coal for replacing coke in pyrogenic electric furnace smelting

An electric furnace smelting and mobile technology, which is applied in the direction of furnace, furnace components, electric charge control, etc., can solve the problems of large volume, uneven distribution of temperature and oxygen content, low reduction reaction efficiency, etc., and achieve the goal of saving electric energy and coke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

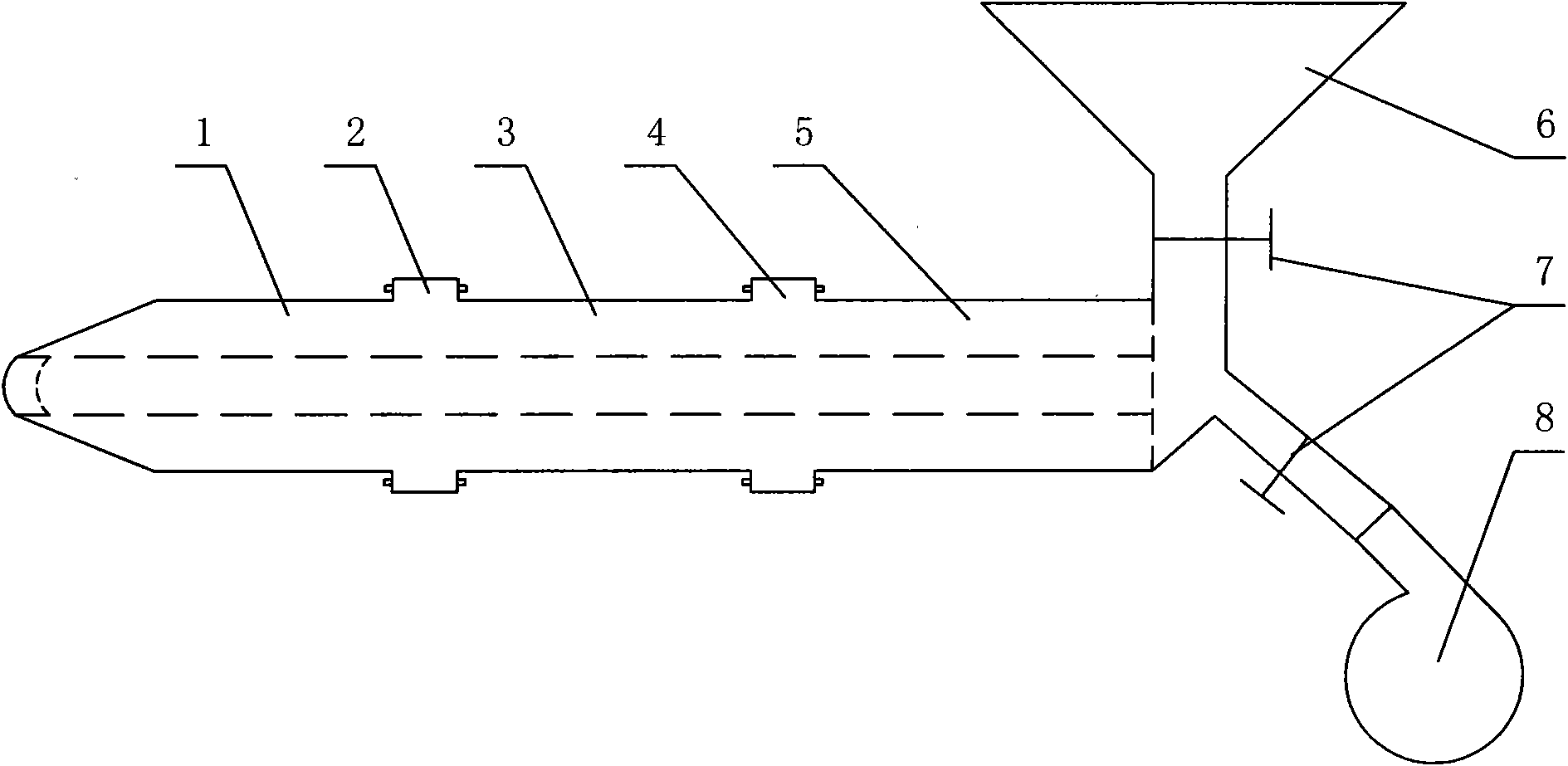

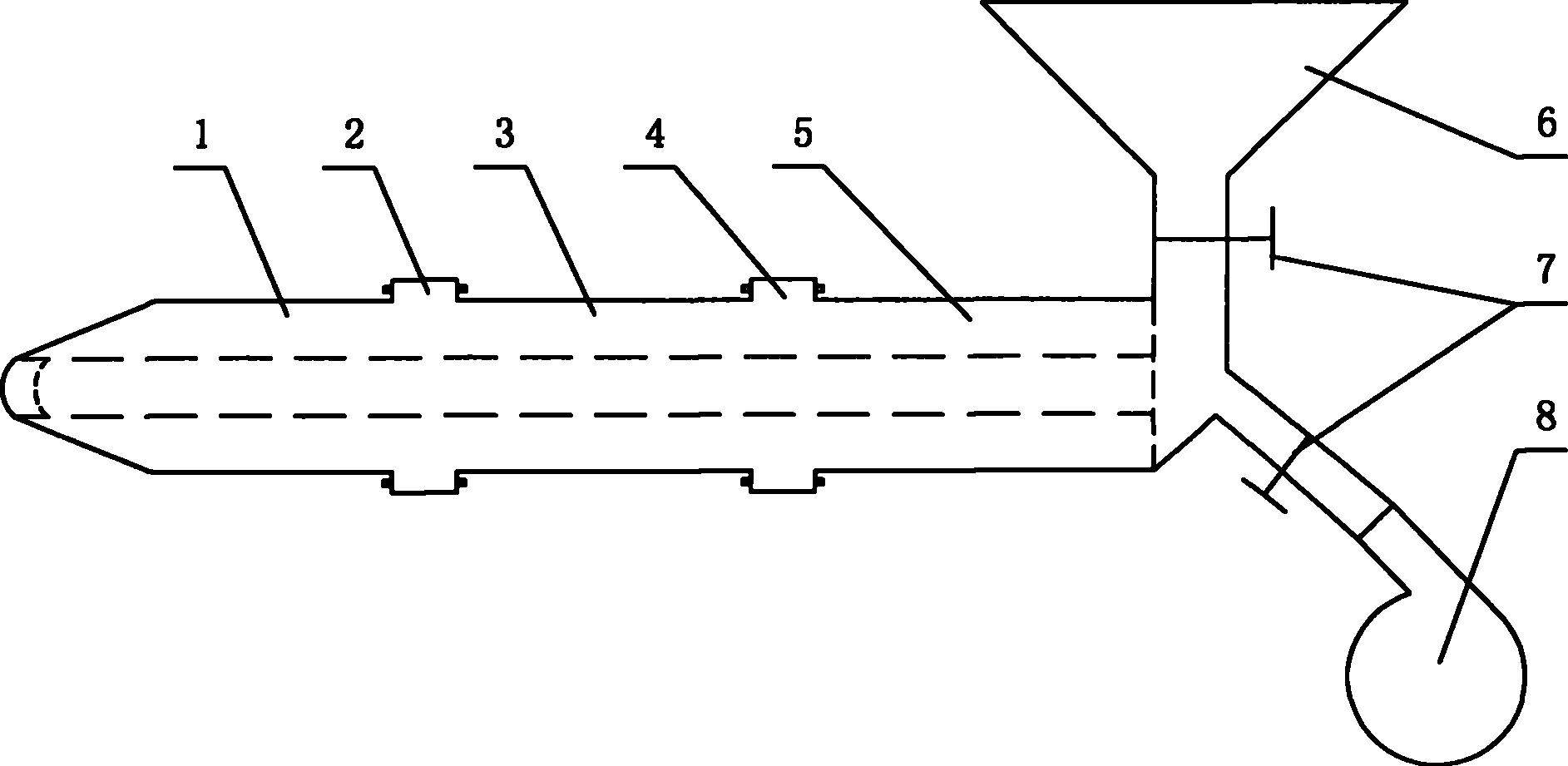

Image

Examples

Embodiment 1

[0019] In the 1800KVA ferroalloy smelting furnace, only 20% of the total weight of coke required by the current conventional process is added to the raw materials. When the raw materials in the smelting furnace are heated to a molten state, the bituminous coal powder is introduced below the liquid level in the furnace. mixture with air. The amount of bituminous coal powder injected is 4 times the weight of coke in the raw material. The particle size of bituminous coal powder is 100 mesh. Change the injection location. The amount and flow rate of the air need not be specifically limited, as long as the bituminous coal powder can be injected smoothly.

[0020] Compared with the current conventional process, the average power consumption is reduced by 18%.

Embodiment 2

[0022] In the 6300KVA ferroalloy smelting furnace, only 25% of the total weight of coke required by the current conventional process is added to the raw materials. When the raw materials in the smelting furnace are heated to a molten state, the bituminous coal powder is introduced below the liquid level in the furnace. mixture with air. The amount of bituminous coal powder injected is 3 times the weight of coke in the raw material. The particle size of bituminous coal powder is 80 mesh. Change the injection location. The amount and flow rate of the air need not be specifically limited, as long as the bituminous coal powder can be injected smoothly.

[0023] Compared with the current conventional process, the average power consumption is reduced by 20%.

Embodiment 3

[0025] In the 8000KVA calcium carbide smelting furnace, only 23% of the total weight of coke required by the current conventional process is added to the raw materials. When the raw materials in the smelting furnace are heated to a molten state, the bituminous coal powder is introduced below the liquid level in the furnace mixture with oxygen. The amount of bituminous coal powder injected is 3.5 times the weight of the coke in the raw material. The particle size of the bituminous coal powder is 120 mesh. Change the injection location. The amount and flow rate of oxygen do not need to be specifically limited, as long as the bituminous coal powder can be injected smoothly.

[0026] Compared with the current conventional process, the average power consumption is reduced by 23%.

[0027] Since there are many types of pyrometallurgy electric furnaces with large power, and the processes of each enterprise are also different, the "total weight of coke required by the current conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com