Method for manufacturing bottom gate type FED lower plate pattern by adopting positive photoresist

A technology of positive photoresist and photoresist, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., and can solve problems such as grid layer 5 short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

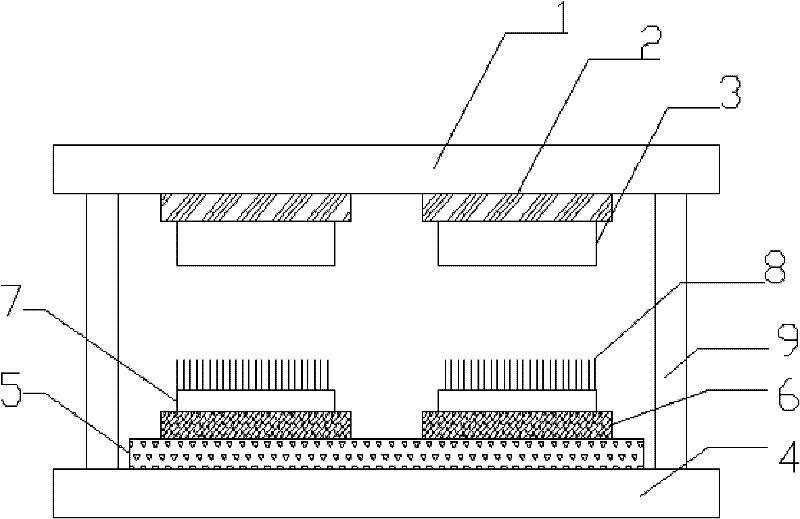

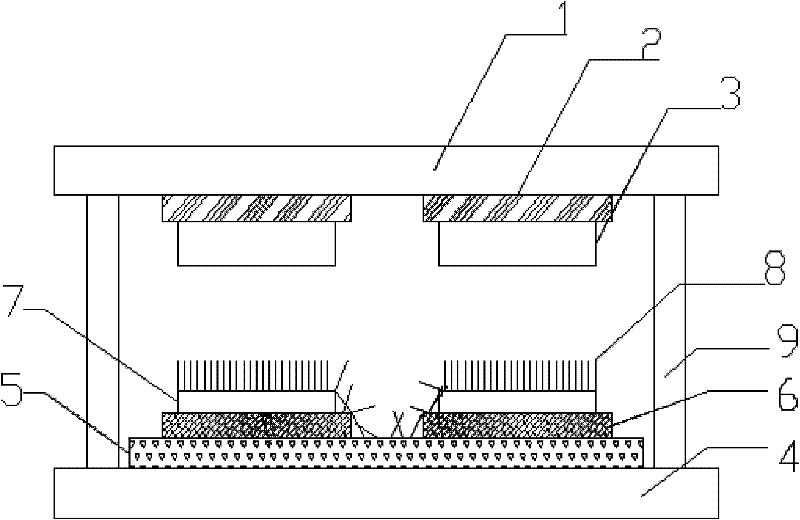

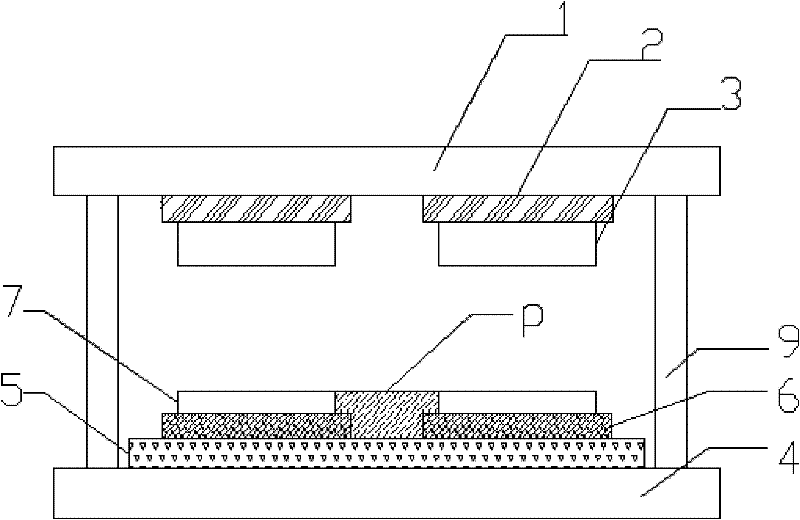

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation of photosensitive silver paste:

[0046] The photosensitive silver paste consists of 60 parts by weight of silver monomer, 30 parts by weight of methacrylic resin, 4 parts by weight of photoinitiator 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester, 5 parts by weight Parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and 1 part by weight of polymer dispersant BYK410 are mixed and ground uniformly;

[0047] 2) On the cathode glass substrate 4 after cleaning, use the photosensitive silver paste described in the above step 1) to make the pattern of the gate layer 5 by photolithography;

[0048] The steps of making the gate layer 5 graphics specifically include:

[0049] a). On the cathode glass substrate 4 after cleaning, print a layer of photosensitive silver paste in step 1) to prepare a silver electrode layer;

[0050] b). The substrate in step a) is baked in an oven at a temperature of 95°C for 30 minutes, and then cooled naturally;

[00...

Embodiment 2

[0066] 1) Preparation of photosensitive silver paste:

[0067] The photosensitive silver paste consists of 80 parts by weight of silver monomer, 10 parts by weight of methacrylic resin, 1 part by weight of photoinitiator 2-methyl-1-[4-methylthiophenyl]-2-morpholine Base-1-acetone, 8.5 parts by weight of 2,2,4-trimethyl-1,3 pentanediol monoisobutyrate and 0.5 parts by weight of polymer dispersant BYK180;

[0068] 2) On the cathode glass substrate 4 after cleaning, use the photosensitive silver paste described in the above step 1) to make the pattern of the gate layer 5 by photolithography;

[0069] The step 2) of making gate layer 5 graphics specifically includes:

[0070] a). On the cathode glass substrate 4 after cleaning, print a layer of photosensitive silver paste in step 1) to prepare a silver electrode layer;

[0071] b). The substrate in step a) is baked in an oven at a temperature of 80°C for 40 minutes, and then cooled naturally;

[0072] c) Use the mask plate of t...

Embodiment 3

[0084] 1) Preparation of photosensitive silver paste:

[0085] The photosensitive silver paste consists of 50 parts by weight of silver monomer, 29 parts by weight of methacrylic resin, 5 parts by weight of photoinitiator 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester, 15 parts by weight Parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and 1 part by weight of polymer dispersant BYK410 are uniformly mixed to form;

[0086] 2) On the cathode glass substrate 4 after cleaning, use the photosensitive silver paste described in the above step 1) to make the gate layer 5 pattern by photolithography;

[0087] The steps of making the gate layer 5 graphics specifically include:

[0088] a). On the cathode glass substrate 4 after cleaning, print two layers of photosensitive silver paste in step 1) to prepare a silver electrode layer,

[0089] b). The substrate in step a) is baked in an oven at a temperature of 120°C for 10 minutes, and then cooled naturally;

[0090] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com