Method for sealing large-power LED

A LED packaging, high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty in finding phosphor silica gel, reduced chip luminous efficiency, shortened LED life, etc., to achieve the effect of increasing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

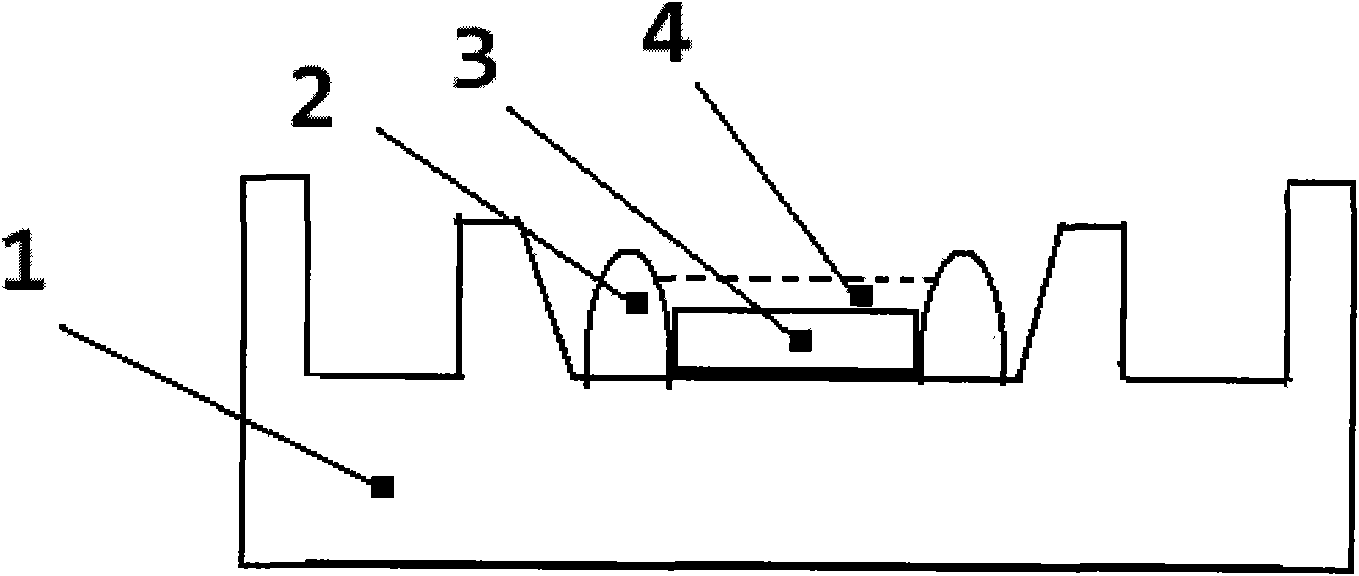

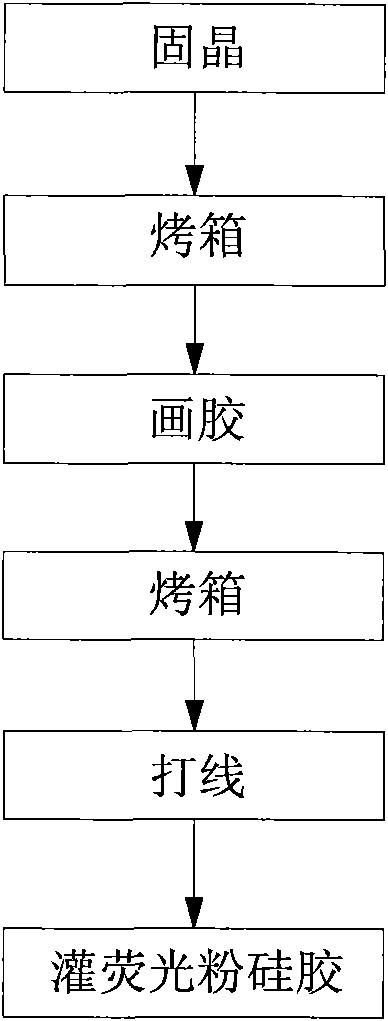

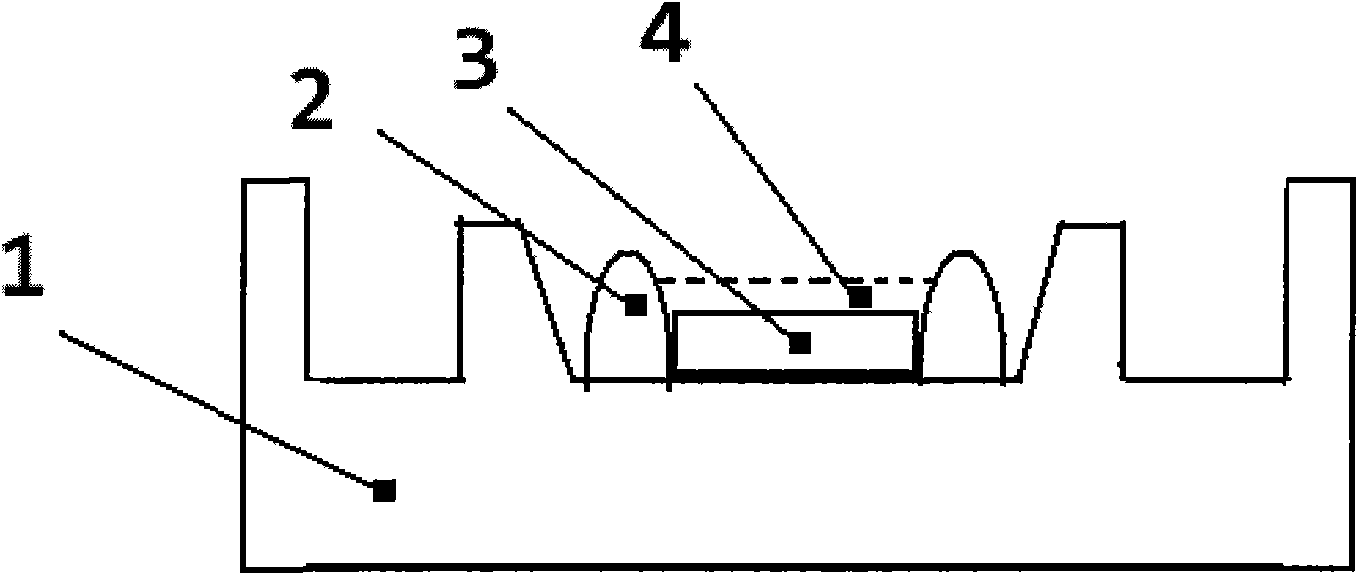

[0017] like Figure 1-2 As shown, a high-power LED packaging method described in the embodiment of the present invention includes the following steps:

[0018] 1) Fixing the LED die chip 3 on the support 1;

[0019] 2) Put the bracket 1 on which the light-emitting diode die chip 3 is fixed into the oven, the temperature of the oven is 120° C., and the curing time is 60 minutes;

[0020] 3) Use a glue dispenser to paint or dispense silica gel with a suitable viscosity coefficient around the LED die chip 3, and coat a layer of silica gel fence 2 around the LED die chip 3. The silica gel fence 2 can be used according to the desired The required thickness of fluorescent powder silica gel 4 is used for single or multiple glue painting and dispensing. When the required thickness is high, the 3D glue painting function can be used to coat the silica gel fence 2 once and then coat the silica gel fence 2 again. The height of the silicone wall 2 is determined according to the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com