Piezoelectric self-generating unit for generating electric charge by utilizing direct piezoelectric effect

A piezoelectric effect and self-generating technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problems of limited commercial products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]1) Place the cleaned and dried 2 pieces of piezoelectric ceramic sheets and the metal substrate on the operating platform with the adhesive side facing up. Take a small amount of glue for bonding and apply it on the piezoelectric sheet and the metal conductive material, scrape the glue evenly with a small scraper, and quickly stick the two together while applying pressure evenly. After the bonding is completed, the piezoelectric ceramic element is pressed under the plate and left for 24 hours.

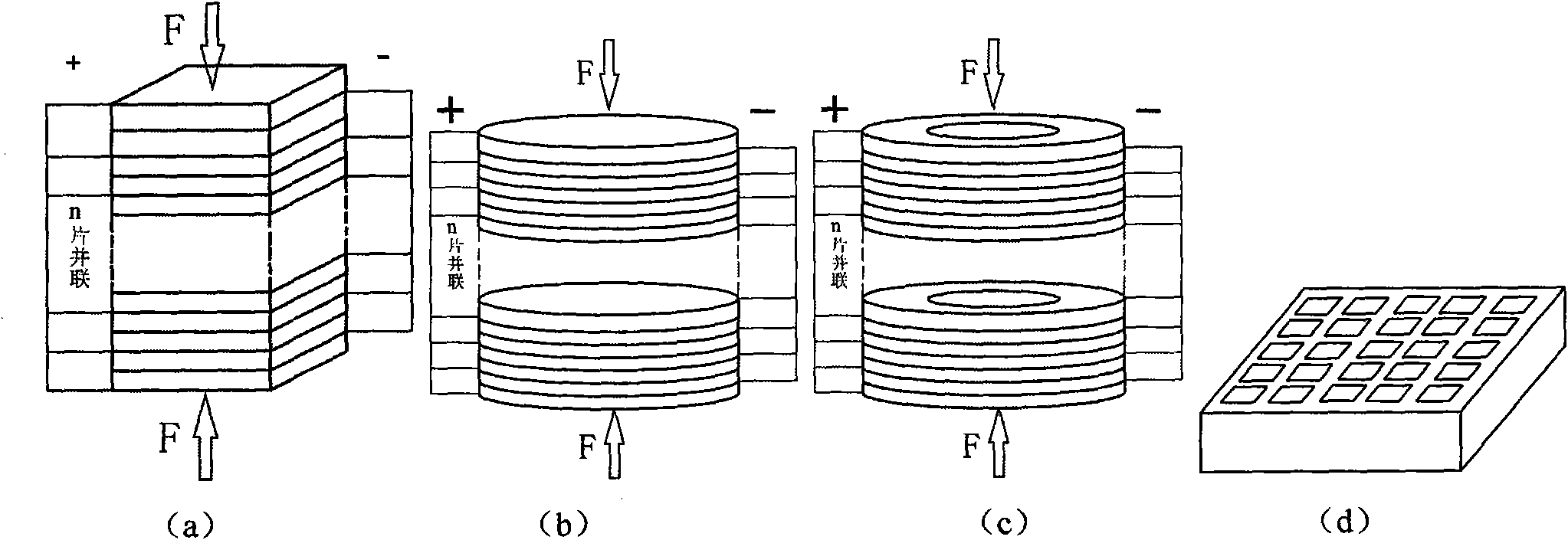

[0029] 2) The piezoelectric ceramic element obtained in step 1 is according to image 3 Solder electrodes as shown.

[0030] 3) The piezoelectric ceramic element obtained in step 2 is potted with epoxy resin, and cured and molded in the range of 60-100°C. That is, a piezoelectric self-generating unit is obtained.

[0031] 4) Connect the piezoelectric self-generating unit to the circuit, and act on the QCZ-2 multi-purpose automatic rutting tester for scientific research, using ...

Embodiment 2

[0033] 1) Place the washed and dried 8 pieces of piezoelectric ceramic sheets and metal substrate on the operating platform with the bonding side facing up. Take a small amount of glue for bonding and apply it on the piezoelectric sheet and the metal conductive material, scrape the glue evenly with a small scraper, and quickly stick the two together while applying pressure evenly. After the bonding is completed, the piezoelectric ceramic element is pressed under the plate and left for 24 hours.

[0034] 2) The piezoelectric ceramic element obtained in step 1 is according to image 3 Solder electrodes as shown.

[0035] 3) The piezoelectric ceramic element obtained in step 2 is potted with epoxy resin, and cured and molded in the range of 60-100°C. That is, a piezoelectric self-generating unit is obtained.

[0036] 4) Connect the piezoelectric self-generating unit to the circuit, and act on the QCZ-2 multi-purpose automatic rutting tester for scientific research, using the f...

Embodiment 3

[0038] 1) Place the cleaned and dried 10 pieces of piezoelectric ceramic sheets and metal substrates on the operating platform with the adhesive side facing up. Take a small amount of glue for bonding and apply it on the piezoelectric sheet and the metal conductive material, scrape the glue evenly with a small scraper, and quickly stick the two together while applying pressure evenly. After the bonding is completed, the piezoelectric ceramic element is pressed under the plate and left for 24 hours.

[0039] 2) The piezoelectric ceramic element obtained in step 1 is according to image 3 Solder electrodes as shown.

[0040] 3) The piezoelectric ceramic element obtained in step 2 is potted with epoxy resin, and cured and molded in the range of 60-100°C. That is, a piezoelectric self-generating unit is obtained.

[0041] 4) Connect the piezoelectric self-generating unit to the circuit, and act on the QCZ-2 multi-purpose automatic rutting tester for scientific research, using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com