Method and gaskets for casting acrylic films

An acrylic resin and acrylate technology, applied in other household appliances, flat products, household appliances, etc., can solve problems such as difficulty in achieving uniform thickness, wrinkles, and film deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

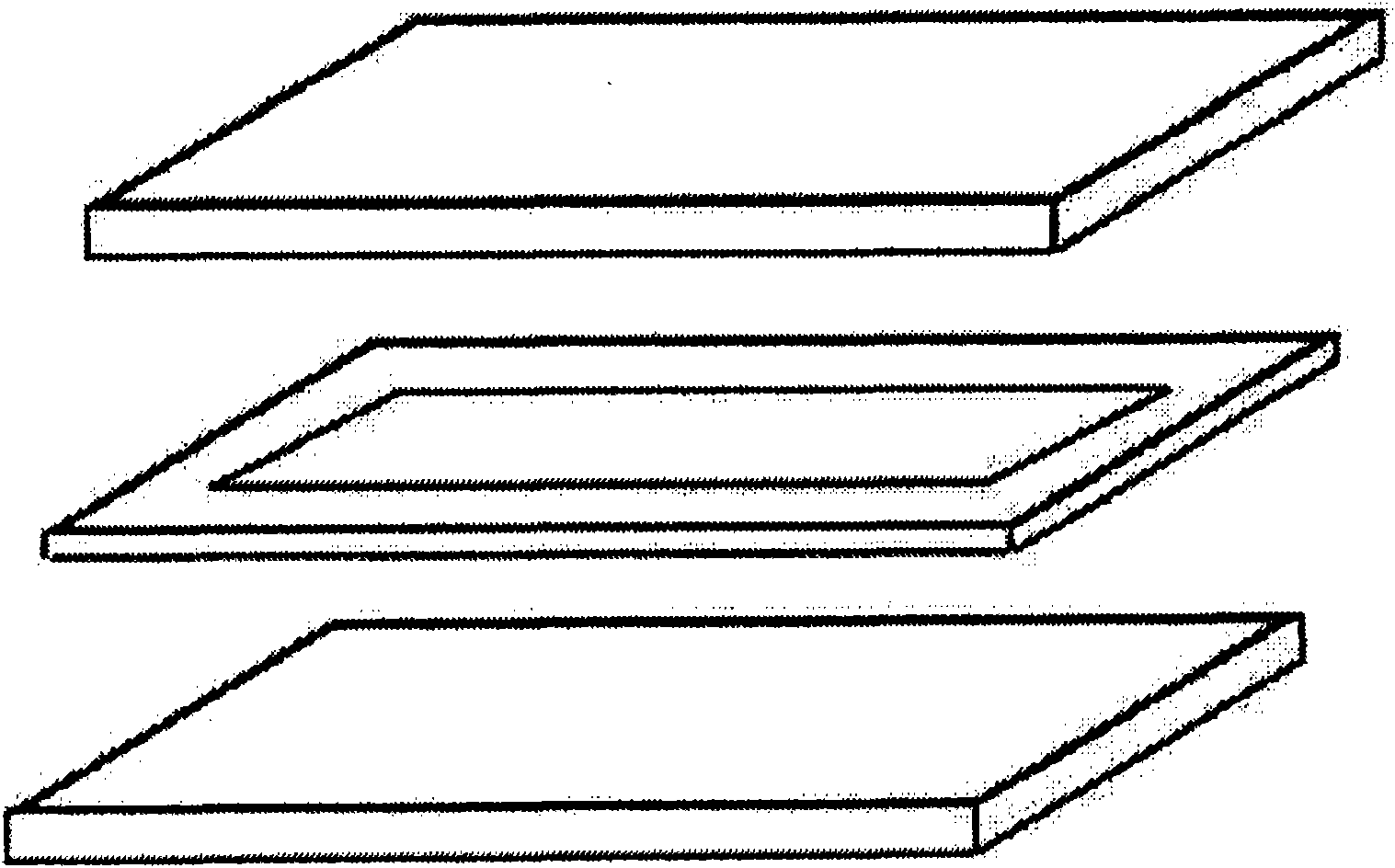

Image

Examples

Embodiment approach

[0036] Hereinafter, the present invention will be described in detail with reference to examples. However, the invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided to fully convey the concept of the present invention to those skilled in the art.

Embodiment 1

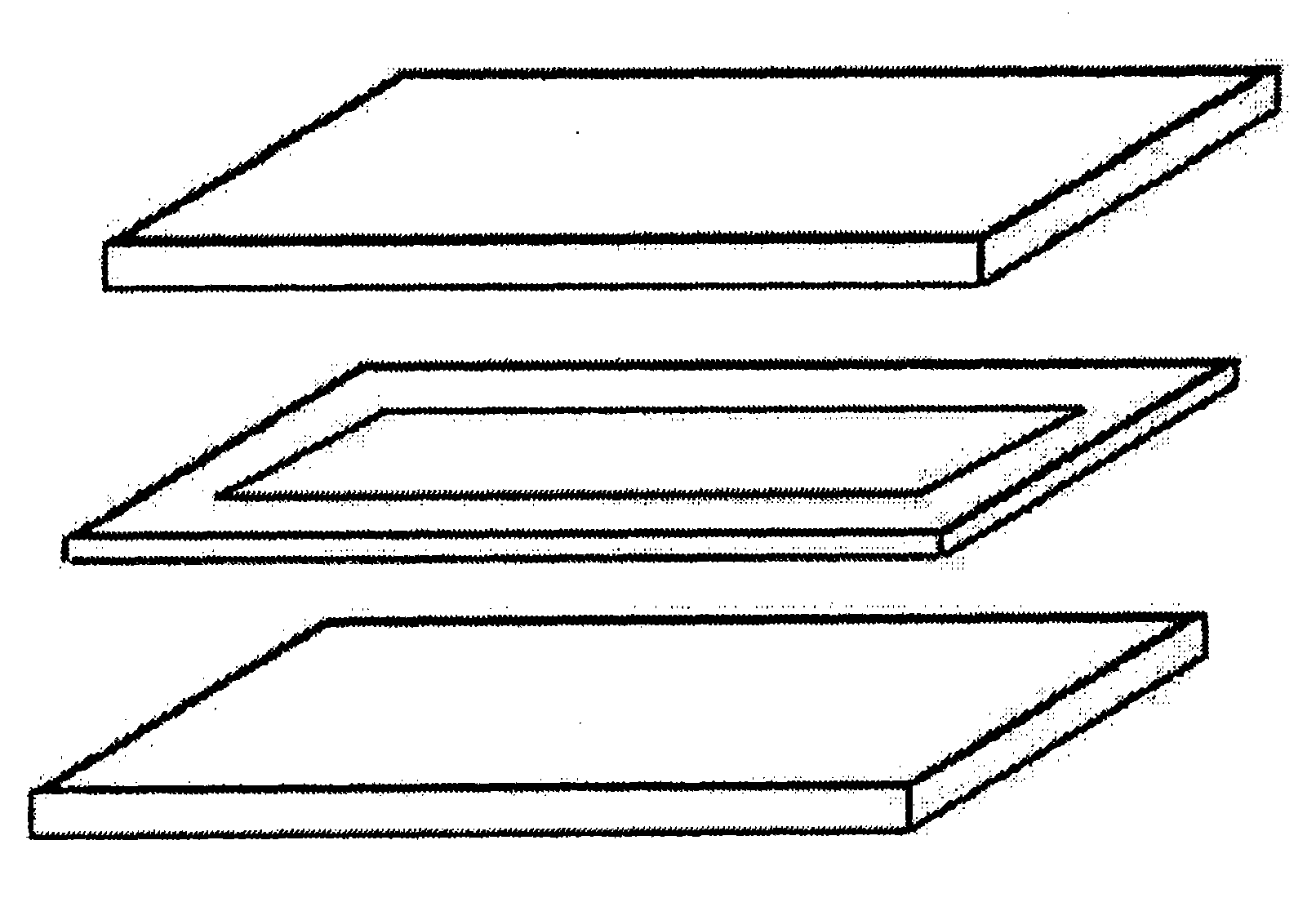

[0042] Acrylic resin films were cast using gaskets made of foamed PVC (polyvinyl chloride) which when cured had a shrinkage of 20% under vacuum compression and showed a thickness change from 500 μm to 400 μm. Use this gasket for cast acrylic films. Specifically, a gasket made of foamed PVC was placed between two glass substrates with a size of 20CM×30CM, a composition containing the materials in Table 1 was injected, and then cured. At this time, the shrinkage ratio of the acrylic resin film material prepared by using the composition including the material of Table 1 was 11%. Curing was performed under the following conditions. Curing was initiated at 25°C under atmospheric conditions and the temperature was gradually increased to 100°C over 4 hours. After keeping it at 100°C for 2 hours, the temperature was lowered to 25°C over 4 hours. After the curing step, the acrylic resin film is separated from the substrate and the spacer, the thickness deviation of the film is not m...

Embodiment 2

[0044] An acrylic resin film was prepared in the same manner as in Example 1 except for using foamed PE (polyethylene), which had a shrinkage rate of 25% under vacuum compression and showed a shrinkage rate of from 400 μm to 300 μm in curing, as the gasket. Thickness changes. After the curing step, the acrylic resin film is separated from the substrate and the spacer, the thickness deviation of the film is not more than 8%, and the thickness is in the range of 305-330 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com