Coin and method for producing a coin

A technology for coins and medals, applied in the field of medals or casino chips, and the field of making coins, can solve the problems of inability to detect coins, not implemented, and small layer thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

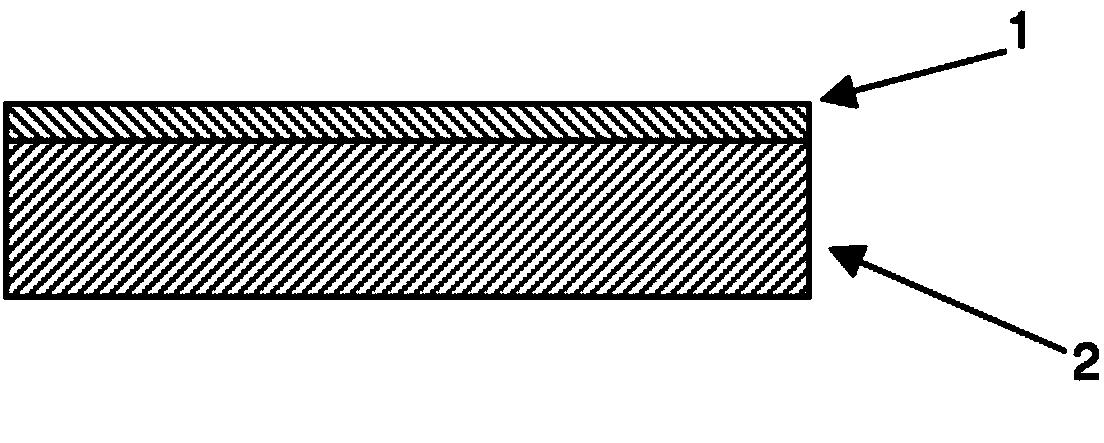

[0067] The coin according to the invention has at least a first layer 1 of a first material, a second layer 2 of a second material and optionally a further second layer 2'. A very thin first layer 1 at least partially forms the first side of the coin, while a second layer 2 is arranged directly below the first layer. The second layer 2 or a further second layer 2' of the same material partially forms the other side of the coin. The other side of the coin can also be partly formed by layer 6 , which will be explained below.

[0068] Basically two goals can be achieved by this setup structure. Firstly, the multicoloredness of the coins is guaranteed by the different materials of the layers. Secondly, the first layer 1 is sufficiently thin and / or the material is selected in such a way that it does not cover or only covers the second layer 2 located beneath it to the extent that it is detected by the electronic coin detection device, i.e. 1 The resulting deviations can be filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com