Single-component polyurethane waterproof coating capable of being formed through one-time construction and application of single-component polyurethane waterproof coating

A polyurethane waterproof, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion of substrates, and achieve improved adhesion, excellent waterproofing, and uniform film thickness. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

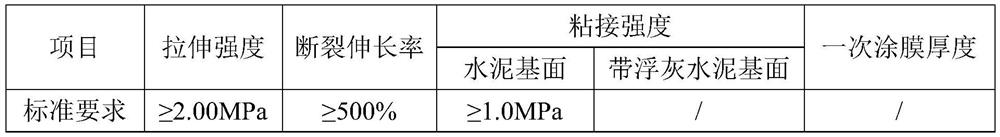

[0041]The difference between Example 1 and Comparative Example 1 is that the design ratio of the thixotropic agent in Comparative Example 1 is different. Comparative Example 1 has a good bonding effect with the surface of the base layer after coating, but the thickness of the primary coating is insufficient, only 0.7mm. The difference between Example 1 and Comparative Example 2 is that in Comparative Example 2, a bentonite thixotropic agent was used to design a thixotropic system. The surface of the base layer of floating ash has poor bonding effect and cannot meet the application requirements. The main difference between Example 1 and Comparative Example 3 is that in Comparative Example 3, the excessive addition of filler does not conform to the design of the present invention, the low elongation of the coating film does not meet the design requirements, and it is difficult to scratch during construction, and the coating film is bonded to the surface of the base layer. The ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com