Highly-concentrated laundry liquid

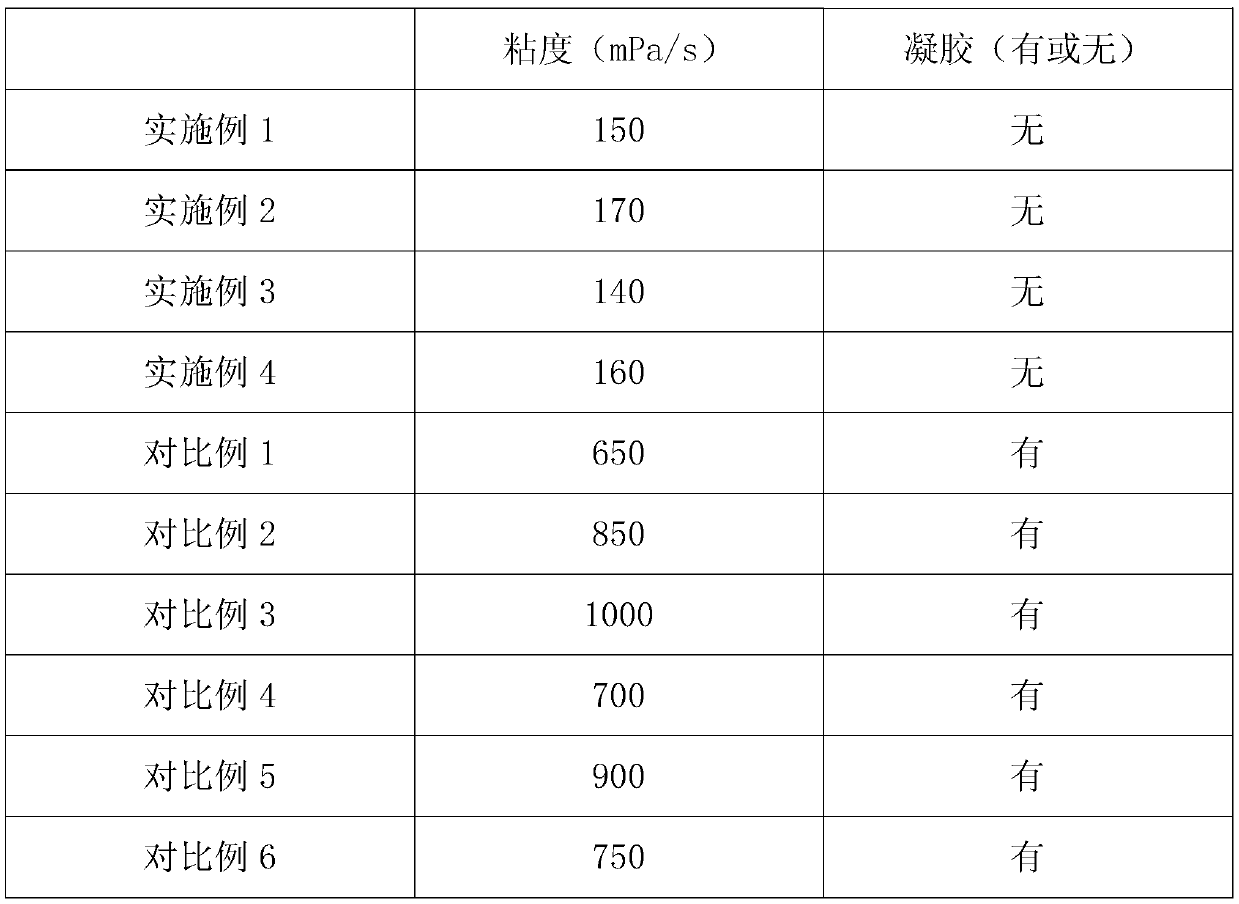

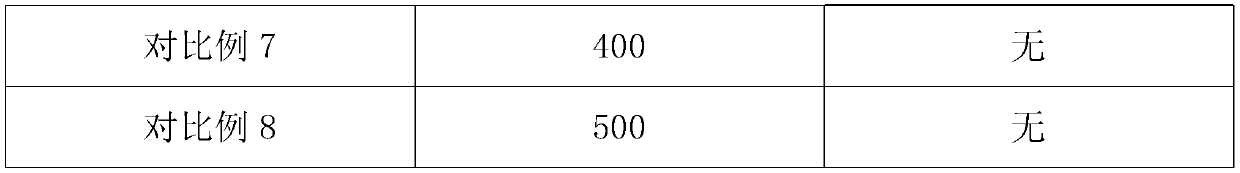

A laundry detergent and high-concentration technology, which is applied in the field of daily chemicals, can solve problems such as difficulty in obtaining ideal products, difficult production and operation processes, and solution-gel dispersibility, and achieve short action time, simple production process and thin viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The highly concentrated laundry detergent is composed of the following substances in parts by mass: 1 part of environment-friendly solvent, 20 parts of C12-15 alkanol polyether sodium sulfate, 10 parts of C12-13 alkanol polyether, and C12-14 olefin sulfonic acid Sodium 10 parts, water 25 parts. The environmentally friendly solvent is a mixture of isohexanediol and diethylhexyl carbonate, and the mass ratio of isohexanediol to diethylhexyl carbonate is 10:1.

[0019] A method for preparing highly concentrated laundry detergent, comprising the following steps, step 1) weighing environment-friendly solvent, C12-15 alkanol polyether sodium sulfate, C12-13 alkanol polyether, C12-14 olefin sulfonate according to the formula Sodium acid. Step 2) Add the formulated amount of environment-friendly solvent, C12-14 sodium olefin sulfonate, C12-13 alkanol polyether, and C12-15 alkanol polyether sodium sulfate into the formulated amount of water, and stir evenly.

Embodiment 2

[0021] The highly concentrated laundry detergent includes the following substances in parts by mass: 20 parts of environment-friendly solvent, 25 parts of C12-15 alkanol polyether sodium sulfate, 40 parts of C12-13 alkanol polyether, C12-14 sodium olefin sulfonate 20 parts, 2 parts of sodium citrate, 40 parts of water, 2 parts of essence, 0.2 parts of methylisothiazolinone, 2 parts of citric acid, the C12-13 alkanol polyether is: C12-13 alkanol polyether Ether-9, C12-13 Pareth-C12-13 Pareth-3 Mixture, C12-13 Pareth-9, C12-13 Pareth-7, C12- The mass ratio of 13 alkanes-3 is 20:15:3, and environment-friendly solvent is the mixture of isohexanediol and diethylhexyl carbonate, and the mass ratio of isohexanediol and diethylhexyl carbonate is 10:1.

[0022] A method for preparing highly concentrated laundry detergent, comprising the following steps, step 1) weighing environment-friendly solvent, C12-15 alkanol polyether sodium sulfate, C12-13 alkanol polyether, C12-14 olefin sulfo...

Embodiment 3

[0024] The highly concentrated laundry detergent includes the following substances in parts by mass: 10 parts of environment-friendly solvent, 22 parts of C12-15 alkanol polyether sodium sulfate, 25 parts of C12-13 alkanol polyether, C12-14 sodium olefin sulfonate 15 parts, 1 part sodium citrate, 1 part essence, 0.1 part methylisothiazolinone, 1 part citric acid, 40 parts water, the C12-13 alkanol polyether is: C12-13 alkanol polyether Ether-9, C12-13 Pareth-C12-13 Pareth-3 Mixture, C12-13 Pareth-9, C12-13 Pareth-7, C12- The mass ratio of 13 pareth-3 is 25:10:1. The environmentally friendly solvent is a mixture of isohexanediol and diethylhexyl carbonate, and the mass ratio of isohexanediol to diethylhexyl carbonate is 10:1.

[0025] A method for preparing highly concentrated laundry detergent, comprising the following steps, step 1) weighing environment-friendly solvent, C12-15 alkanol polyether sodium sulfate, C12-13 alkanol polyether, C12-14 olefin sulfonate according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com