Acid-resistant composite reverse osmosis film

A reverse osmosis membrane, acid-resistant technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, membrane technology, etc., can solve problems restricting the application of composite reverse osmosis membranes, and achieve the effects of acid resistance and hydrophilicity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention is described in detail below:

[0037] Porous supporting membrane preparation: prepare by conventional method, the present invention is to dissolve N with 13% Udel PS3500LCD polysulfone, 0.2% water and 0.1% tensio-active agent, in N-dimethylacetamide, be coated with scraping on polysulfone After immersing in water to gel and remove the solvent, a support membrane with a molecular weight cut off (MWCO) of about 80,000 was obtained. Wherein the surfactant includes at least one of alkylphenol polyoxyethyl ester phosphate, sodium dodecylsulfonate and alkylphenol polyoxyethyl ester phosphate.

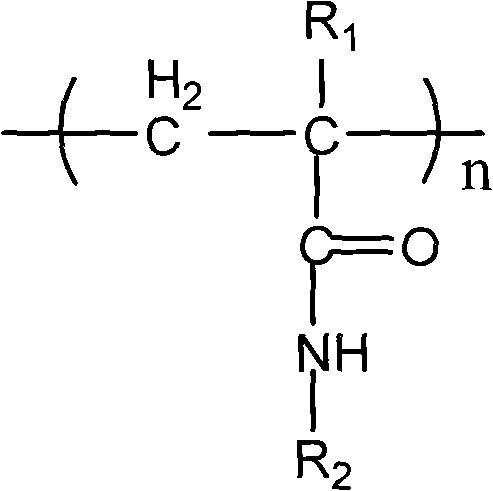

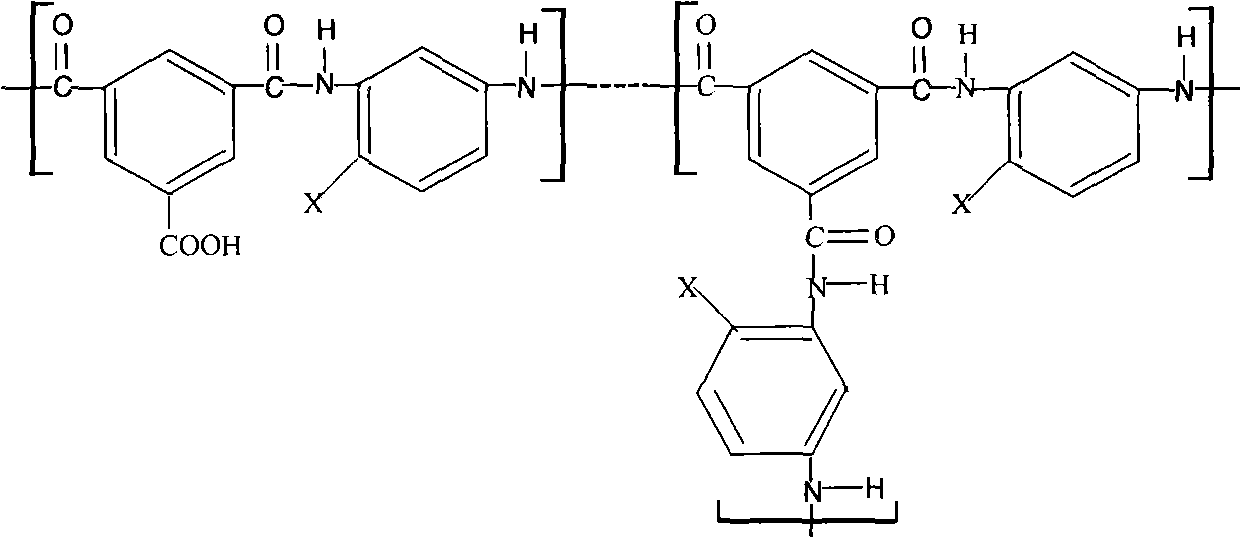

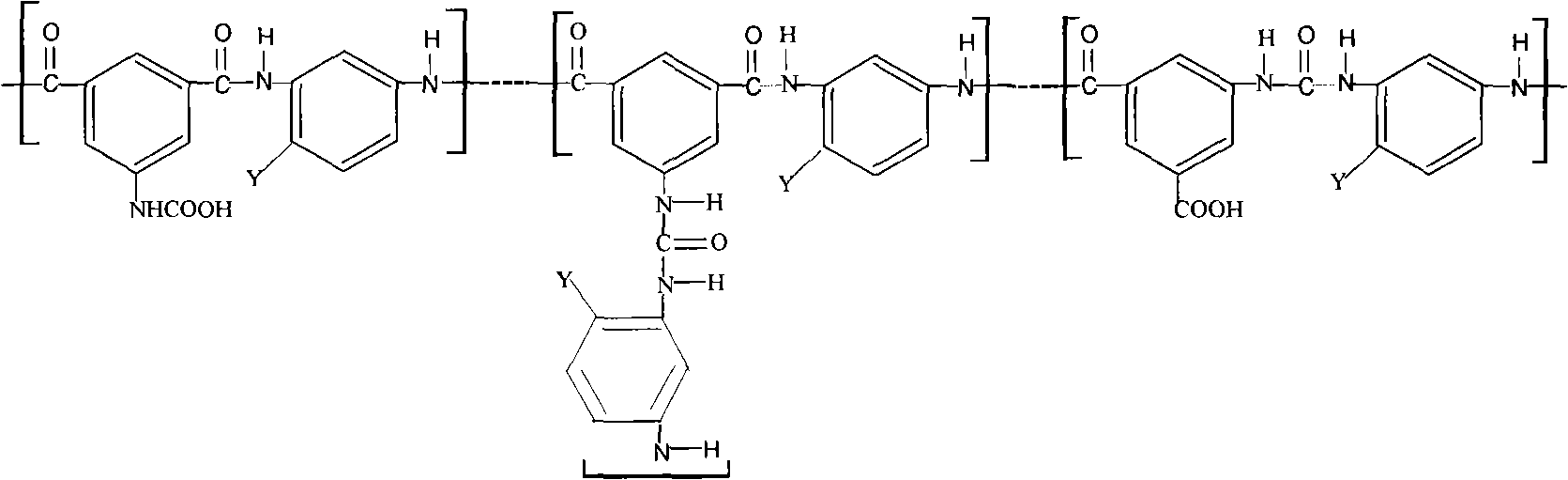

[0038] Preparation of polymer desalination layer: immerse one side of the wet polysulfone support membrane into the polyamine solution, roll the surface of the support membrane with a rubber roller and dry it with compressed air, then contact with the polyacyl chloride solution on one side for interfacial polymerization reaction. The nascen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap