Antibacterial composite reverse osmosis membrane

A technology of reverse osmosis membranes and antibacterial materials, applied in the field of polymer composite membranes, can solve the problems of being unable to inhibit biochemical pollution on the surface of reverse osmosis membranes, achieve good anti-biological pollution performance, simple preparation method, hydrophilicity and antibacterial performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

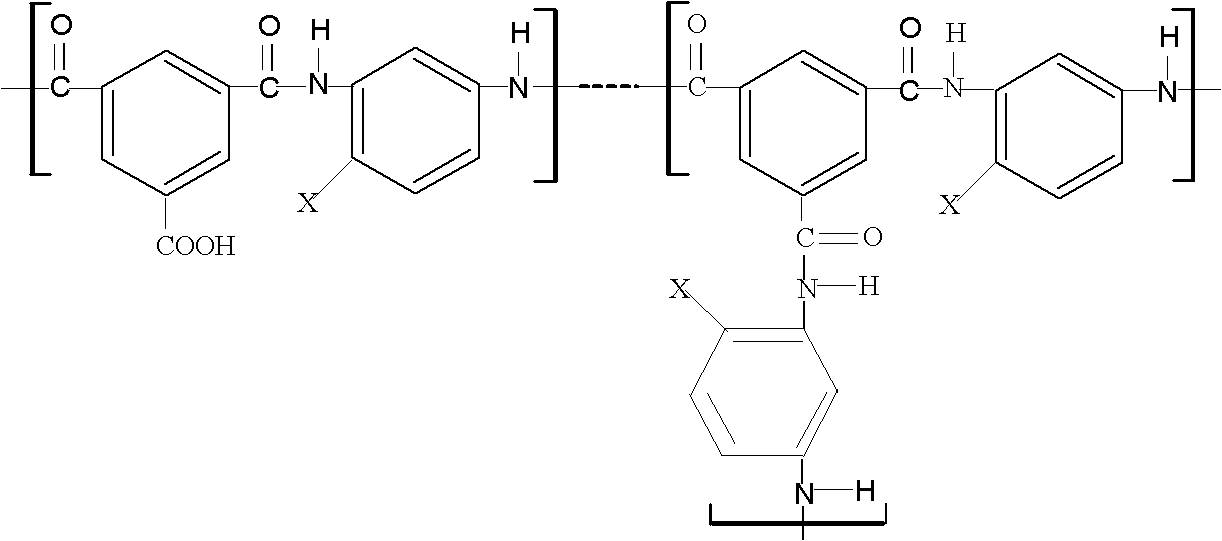

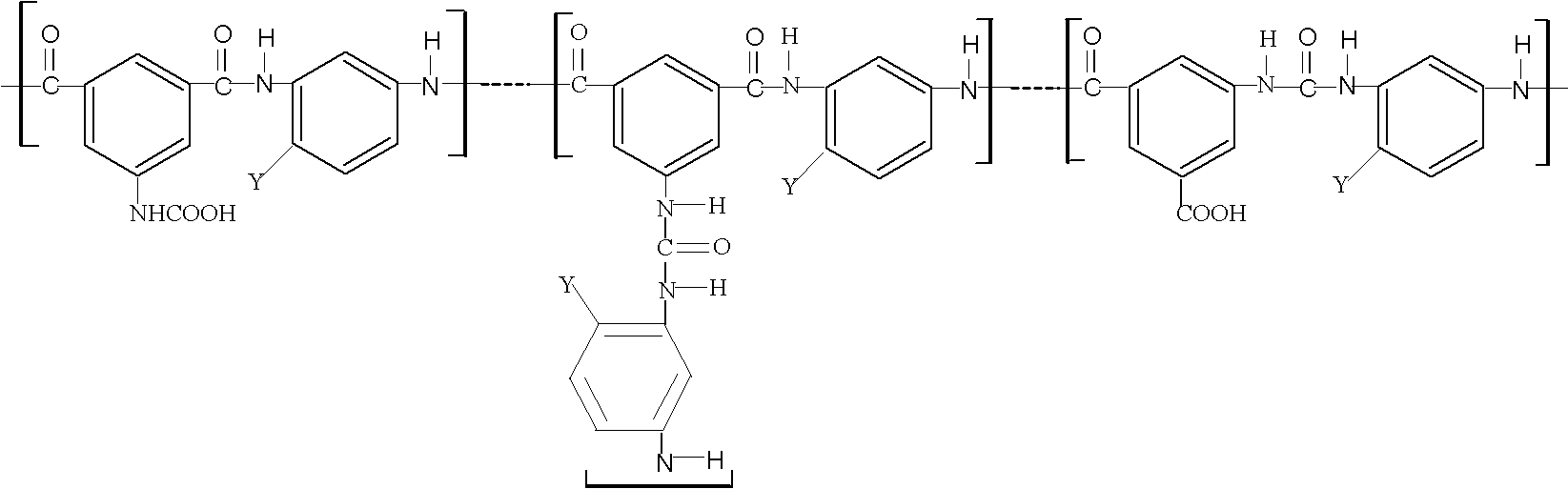

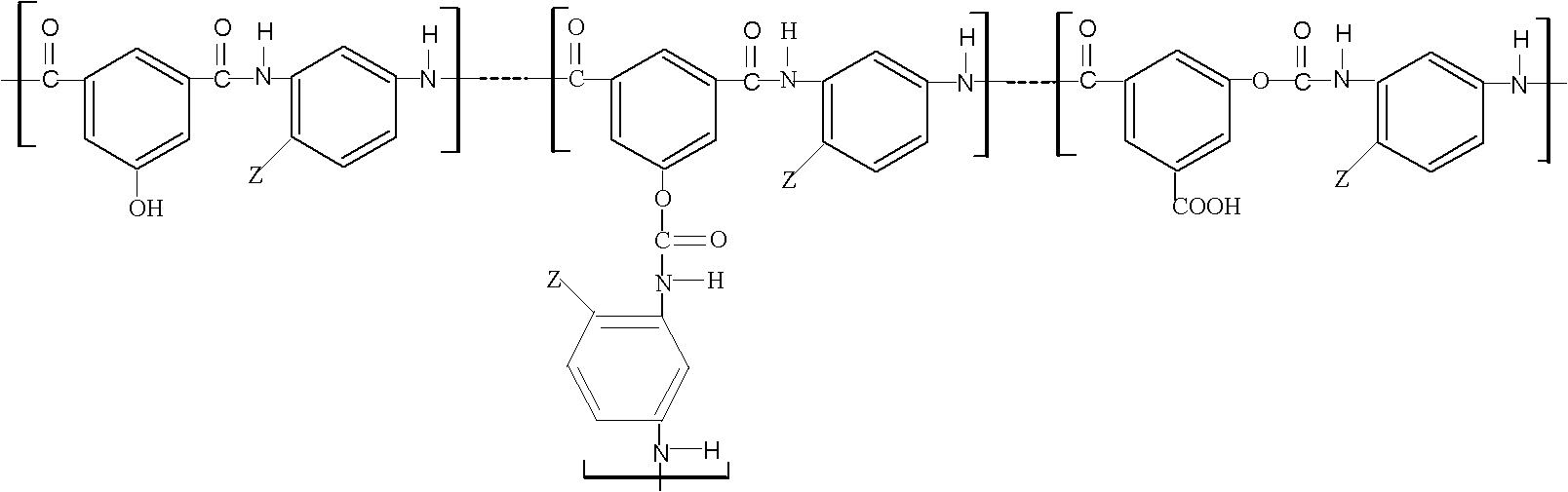

Method used

Image

Examples

Embodiment 9-15

[0051] Table 2: Performance of antibacterial composite reverse osmosis membranes with different thicknesses of antibacterial materials

[0052]

[0053]

[0054] The above examples show that the reverse osmosis membrane with self-cleaning function can be prepared by coating the surface of the composite reverse osmosis membrane with fully aromatic polyamide as the desalination layer with different thicknesses of sericin, and the thickness of the sericin layer is not more than 0.5 μm The anti-homogeneous composite reverse osmosis membrane has the best performance.

Embodiment 16-20

[0056] Table 3: Performance of antibacterial composite reverse osmosis membranes with different antibacterial material layer crosslinking agents

[0057]

[0058]

[0059] The above examples show that the compound reverse osmosis membrane with antibacterial function can be prepared by coating the surface of the composite reverse osmosis membrane with fully aromatic polyamide as the desalination layer with sericin containing cross-linking agent.

Embodiment 21-26

[0061] Table 4: Performance of antibacterial composite reverse osmosis membranes with different antibacterial material layer preparation processes

[0062]

[0063]

[0064]

[0065] The above examples show that the compound reverse osmosis membrane with antibacterial function can be prepared by coating the surface of the composite reverse osmosis membrane with fully aromatic polyamide as the desalination layer with sericin protein containing cross-linking agent, but when the aqueous solution concentration of sericin protein is 100-500mg / l, the best effect is when the aqueous solution concentration of the cross-linking agent is 5-20mg / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com