Antibacterial oxidation-resistant composite reverse osmosis membrane

A technology of reverse osmosis membrane and oxidation resistance, which is applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems that restrict the popularization and application of polyamide composite reverse osmosis membrane, and achieve the improvement of antibacterial performance and oxidation resistance , good antibacterial and oxidation resistance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

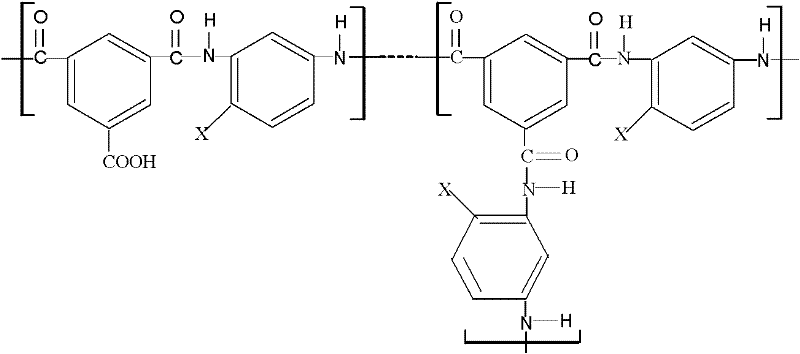

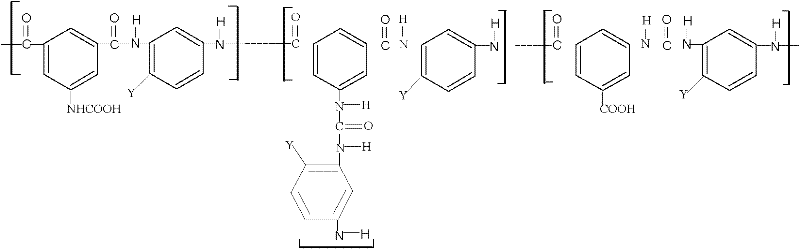

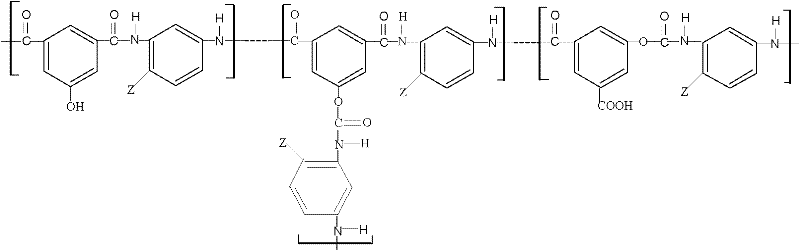

Method used

Image

Examples

preparation example Construction

[0033] The preparation of porous supporting membrane: prepare by conventional method, the present invention is to dissolve in the polar organic solvent with the UDEL PS3500LCD polysulfone of 13.0wt%, the water of 0.3wt% and the tensio-active agent of 0.1wt%, be coated with scraping on polyester After immersing in water to remove solvents and additives, a porous support membrane with a molecular weight cut off (MWCO) of about 80,000 is obtained. Wherein, the surfactant includes at least one of alkylphenol polyoxyethyl ester phosphate, sodium dodecyl sulfonate and alkylphenol polyoxyethyl ester phosphate; the polar organic solvent is N,N-dimethyl Acetamide, or N,N-dimethylformamide, or N-methylpyrrolidone, or a mixture thereof.

[0034] Preparation of polyamide polymer desalination layer: immerse one side of the wet polysulfone support membrane into the polyamine solution, roll the surface of the support membrane with a rubber roller and squeeze it dry, then contact with the pol...

Embodiment 5-8

[0060] Composite reverse osmosis membranes containing different desalination layer materials are prepared by using the existing technology, and then the desalination layer materials are processed in the following three steps in sequence:

[0061] (1) Soak the polymer desalting layer in a solution with a formaldehyde concentration of 5.0 wt %, a pH of 10.0, and a temperature of 60°C for 60 minutes, take it out and wash it with pure water.

[0062] (2) Soak the polymer desalination layer treated above at a pH of 3.0, a temperature of 60° C., and contain 5.0 wt % of hydroxymethylhydantoin in the solution for 30 minutes, and keep it in an oven at 120 degrees for 5 minutes after taking it out. minute.

[0063] (3) Soak the above-treated polymer desalination layer in a solution with an active chlorine concentration of 0.5 wt% and a temperature of 20° C. for 100 minutes, take it out and wash it with pure water.

[0064] The separation performance, antibacterial performance and chlor...

Embodiment 9-14

[0069] The composite reverse osmosis membrane was prepared by the same preparation method as in Example 5 except that the soaking treatment process in the first step was different. The separation performance, antibacterial performance and chlorine resistance performance of the prepared composite reverse osmosis membrane are shown in Table 3.

[0070] Table 3: Examples 9-14

[0071]

[0072]

[0073] The above examples show that the antibacterial and oxidation resistance of the composite reverse osmosis membrane can be improved by soaking the polyamide composite reverse osmosis membrane with formaldehyde solutions of different concentrations, or different pHs, or different temperatures for different times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com