Self-cleaning reverse osmosis membrane

A reverse osmosis membrane, self-cleaning technology, applied in the direction of semi-permeable membrane separation, membrane technology, general water supply saving, etc., can solve complex process, loss of permeation flux of reverse osmosis composite membrane, affect membrane separation performance of charged ions, etc. problem, to achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention is described in detail below:

[0048] Preparation of Porous Supported Membrane: Prepared by conventional method. In the present invention, 15% of Udel PS3500 polysulfone, 0.3% of water and 0.1% of surfactant are dissolved in N,N-dimethylacetamide. On the ester non-woven fabric, and then immersed in water to remove the solvent, a support membrane with a molecular weight cut-off (MWCO) of about 50,000 was obtained. Wherein the surfactant includes at least one of alkylphenol polyoxyethyl ester phosphate, sodium lauryl sulfonate and alkylphenol polyoxyethyl ester phosphate.

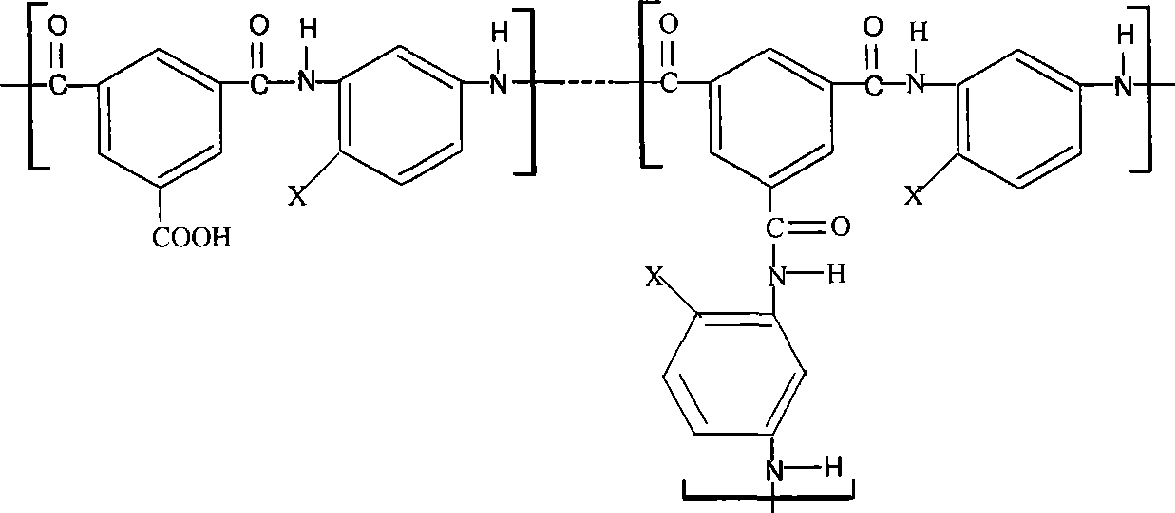

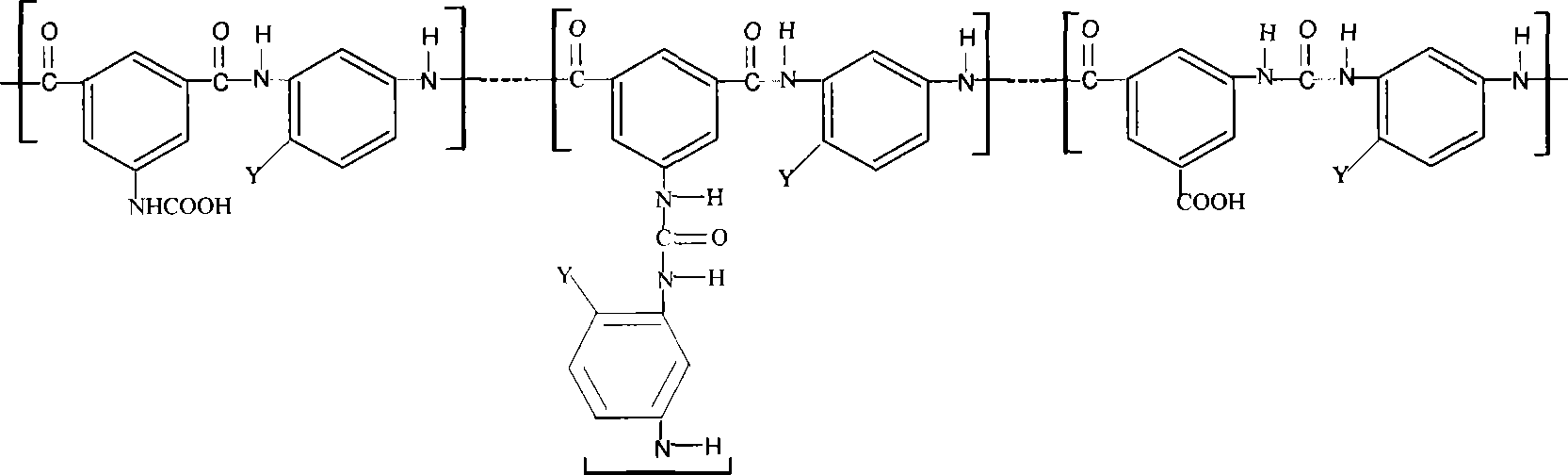

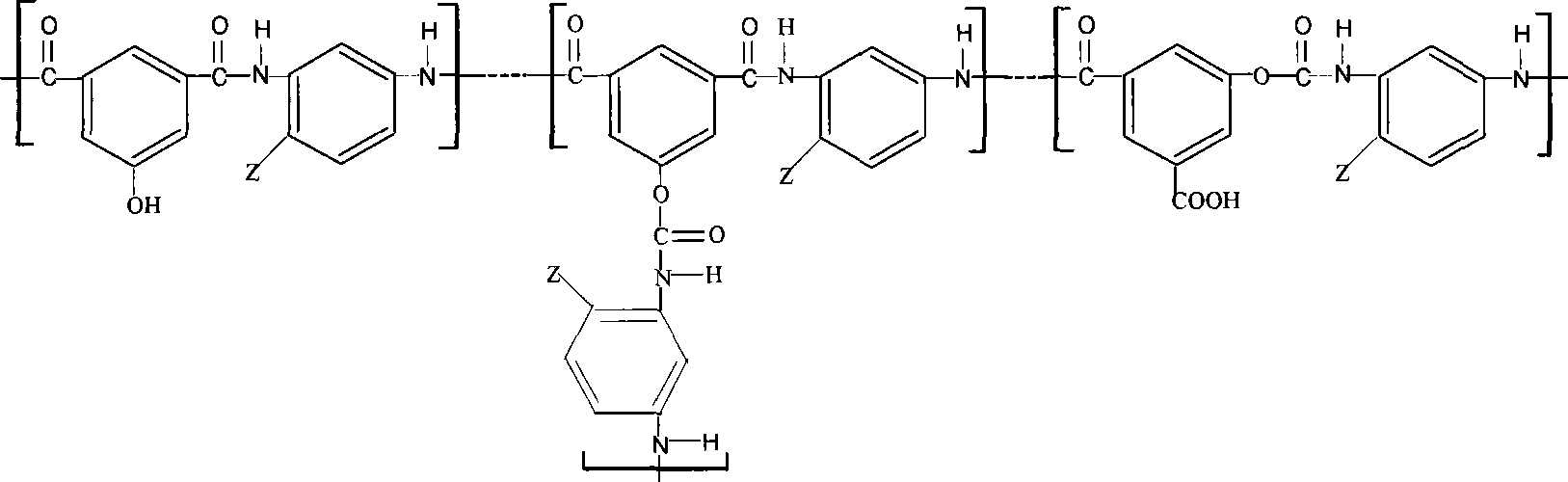

[0049] Preparation of polymer desalination layer: the wet polysulfone support membrane is immersed in polyamine solution on one side, and the surface of the support membrane is squeezed dry with a rubber roller, and then contacted with polyacid chloride solution on one side to carry out interfacial polymerization reaction. The composite film is dried in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com