Box type wire descaling machine

A skin peeling machine and coil wire technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of personal injury and environmental pollution, and achieve the effects of high work efficiency, convenient use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

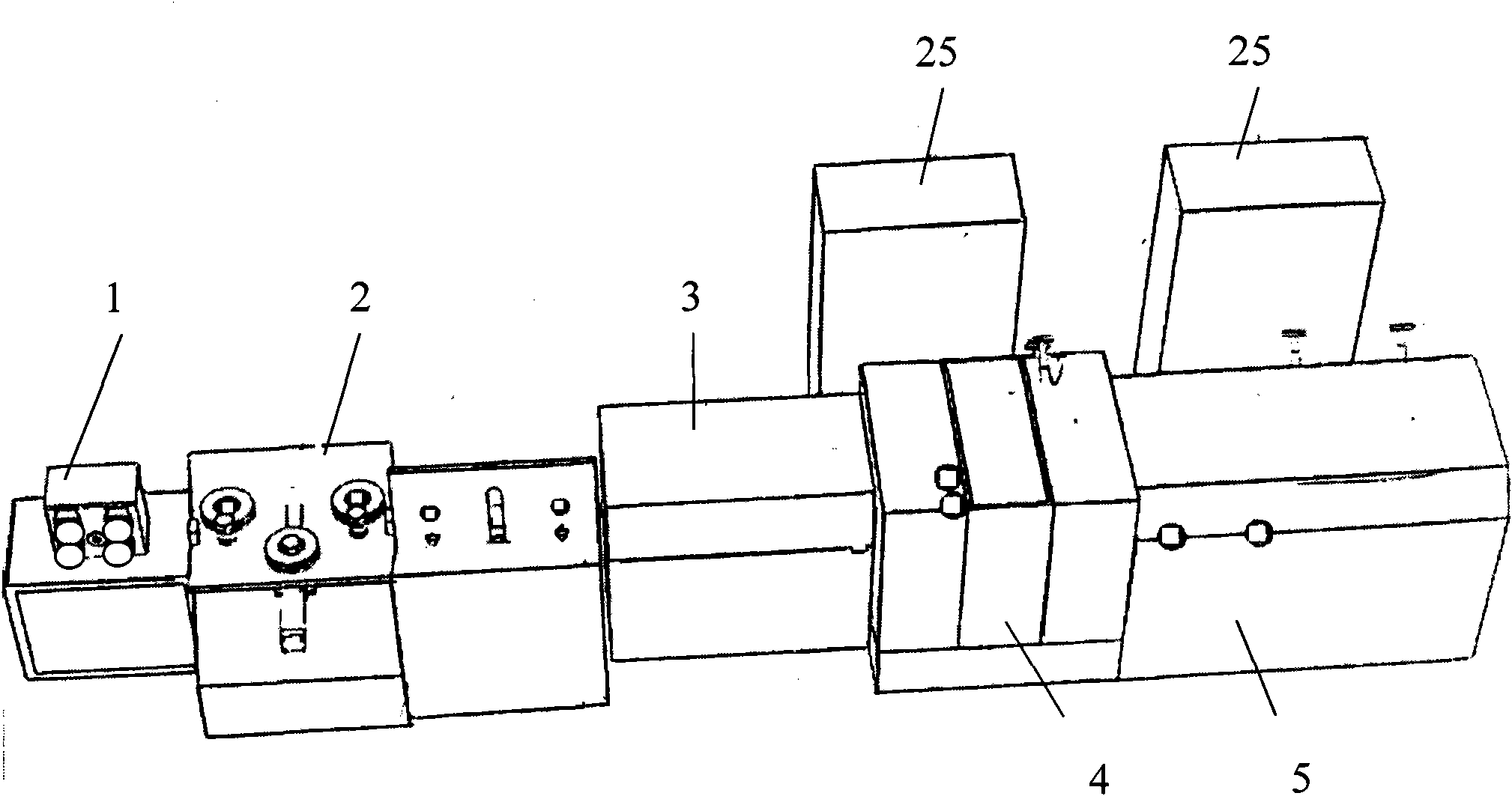

[0028] like figure 1 As shown, the box-type coil wire oxide skin peeling machine is composed of a feeding part 1, a shelling part 2, a rust removal part 3, a cleaning part 4 and a cleaning part 5;

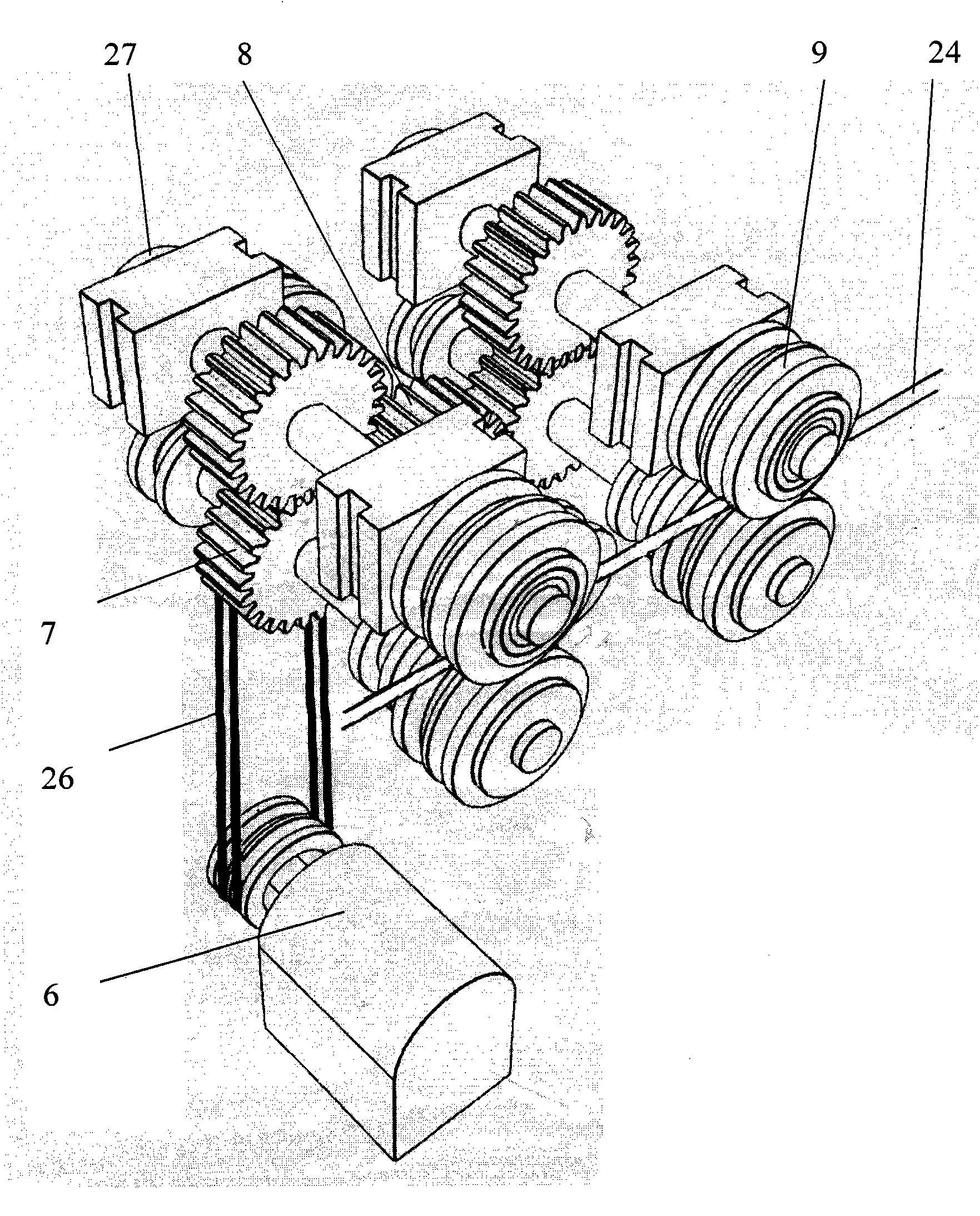

[0029] like figure 2 As shown, the feeding part 1 is composed of a feeding motor 6, a feeding gear 7, an intermediate gear 8 and a feeding roller 9. There are two groups of feeding gears 7 and 9, and the feeding roller 9 is connected with the feeding gear 7 through the rotating shaft. The feeding motor 6 The belt 26 is connected with the intermediate gear 8, and the intermediate gear 8 is connected with the two groups of feeding gears 7; the feeding rollers 9 of the same group are closely contacted by the adjusting handle 27, so as to clamp the wire 24;

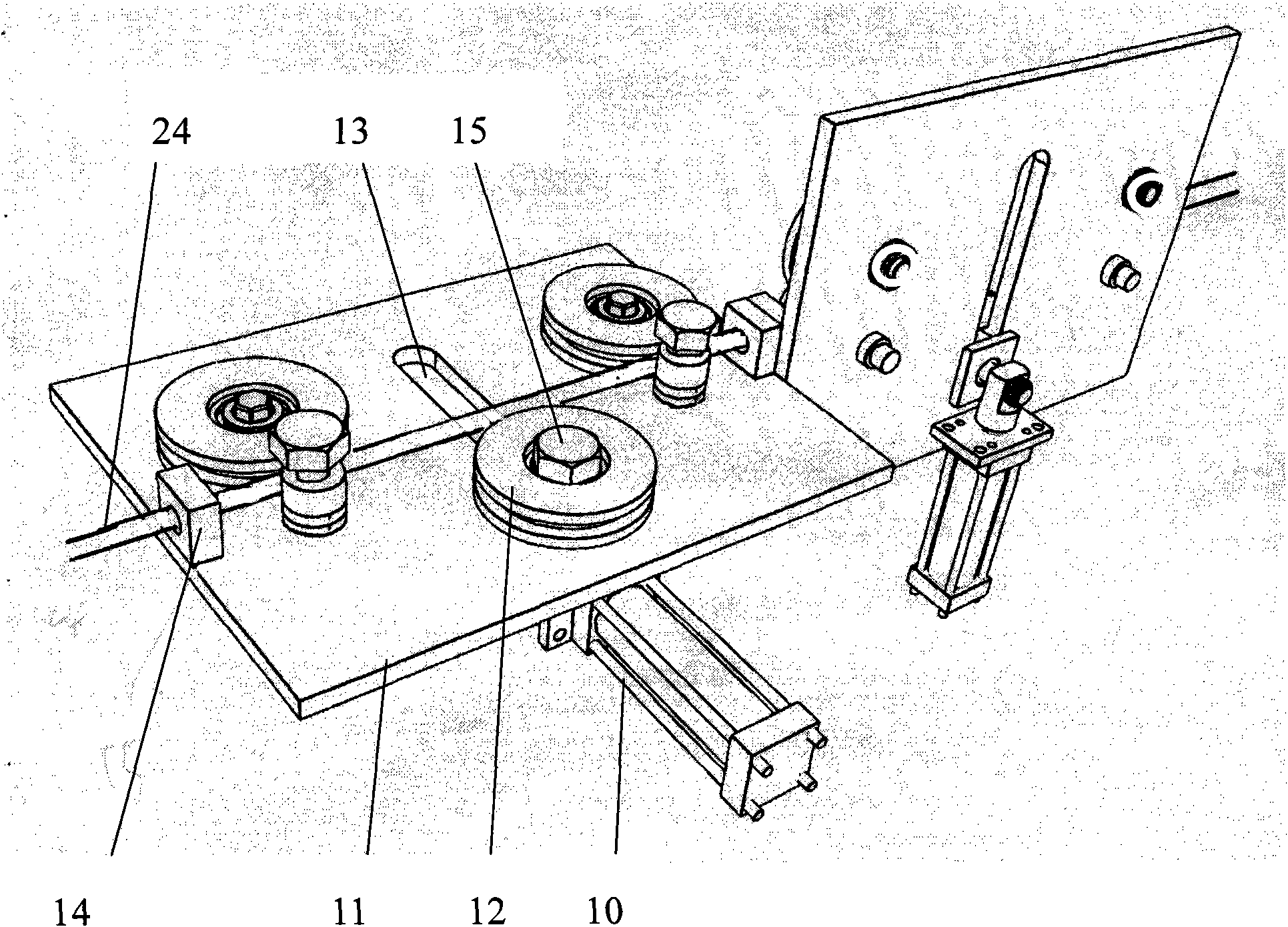

[0030] like image 3 As shown, there are two groups of peeling parts, each group is composed of a top cylinder 10, a fixed plate 11 and a peeling roller 12, there are three peeling rollers 12, and a long hole 13 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com