Oral tube conveying clamp for soft-bag large transfusion production line

A large infusion, production line technology, used in transportation and packaging, manufacturing of rigid/semi-rigid containers, paper/cardboard containers, etc., can solve the problems of complex production line structure, high manufacturing and use costs, and bulky volume, saving space. , the effect of simplifying the structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

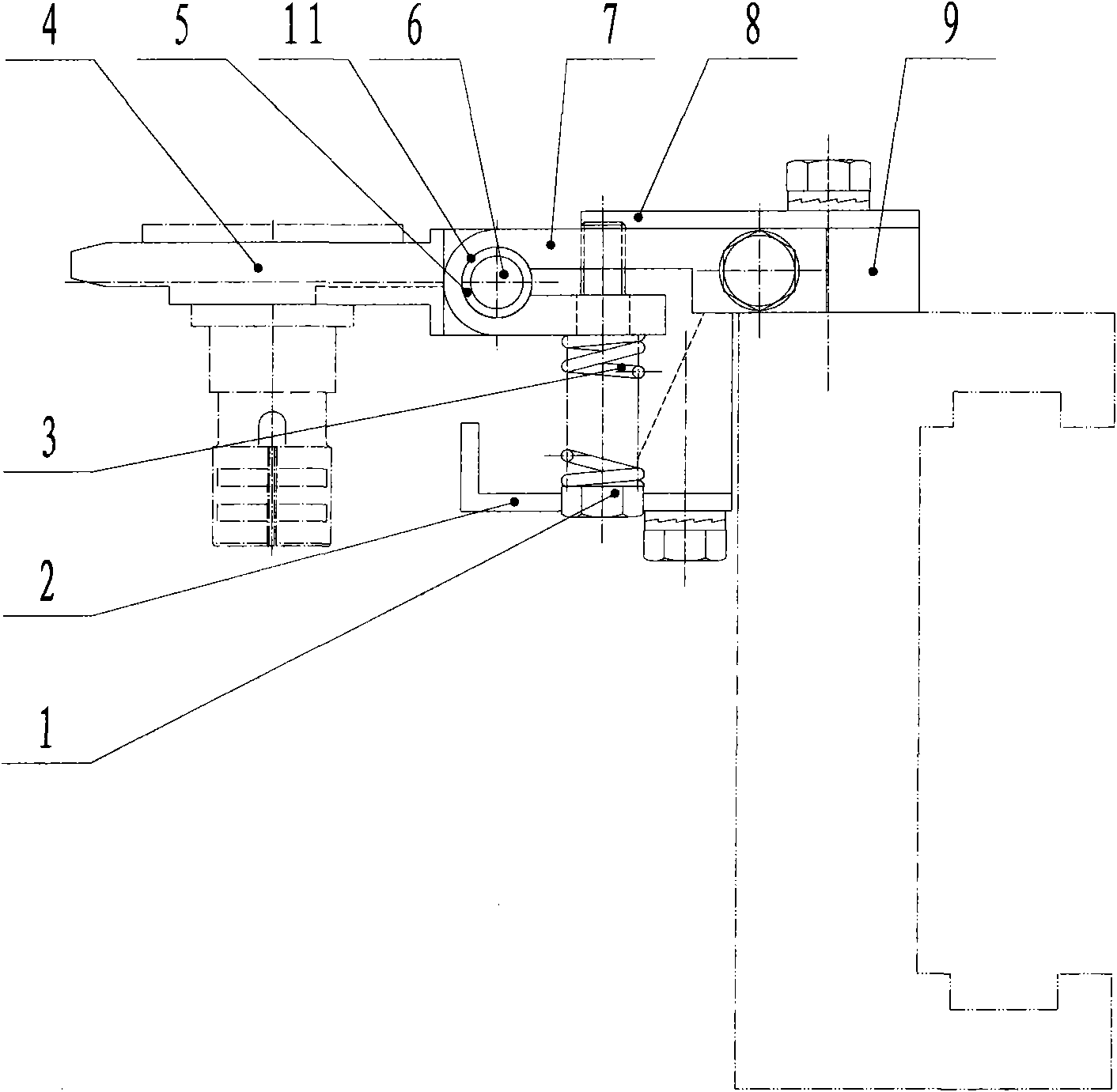

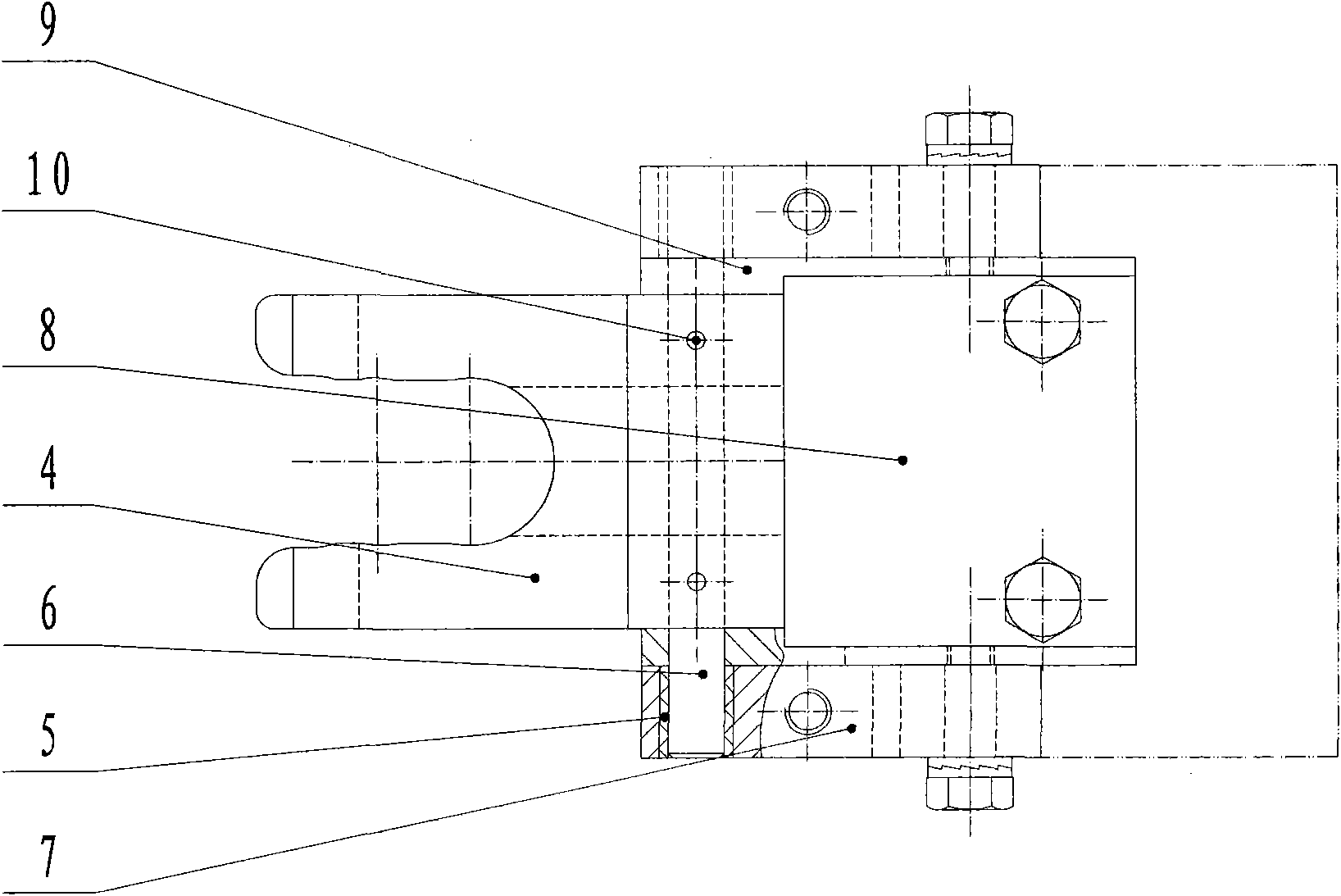

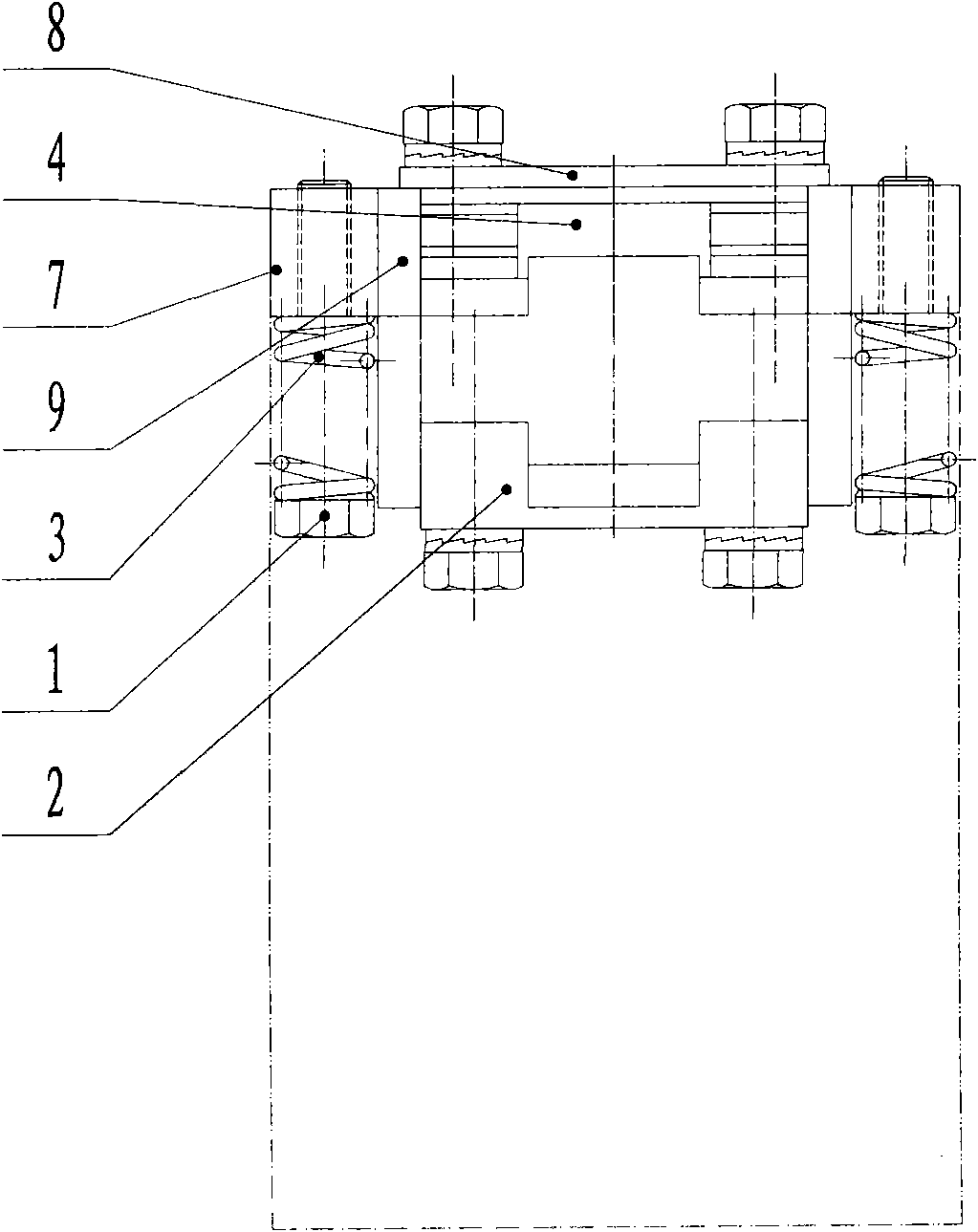

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the oral tube transmission clip used in the soft bag large infusion production line of the present invention includes a chuck 4 and a chuck seat 9, and the chuck 4 used to clamp the oral tube is hinged on the chuck seat 9 through a pin shaft 6, and the pin The shaft 6 is sleeved in the collet 4, and is relatively fixed with the collet 4 through the elastic pin 10, and the pin shaft 6 can rotate freely in the collet seat 9, which is equivalent to that the collet 4 can be opposite to the pin shaft 6 Chuck seat 9 makes relative rotation movement. The chuck seat 9 is provided with a horizontal limiting plate 8 for controlling the horizontal position of the chuck 4 and a vertical limiting plate 2 for controlling the vertical position of the chuck 4, that is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap